Product Introduction

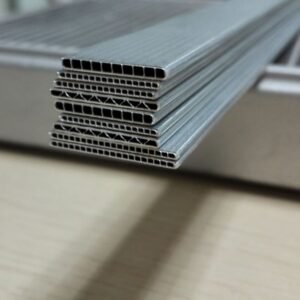

Aluminum Microchannel Tube 1-220 mm Wall

Aluminum microchannel tube (industry aliases: multi-hole extruded tube, flat multi-port tube, MPE tube) pushes wall bandwidth to an industry-leading 1 mm–220 mm, giving design engineers freedom to optimize surface-to-volume ratios from 50 m²/m³ up to 1 200 m²/m³.

The enlarged internal fin-to-channel interface lifts overall heat-transfer coefficient (HTC) by ≥30 % versus conventional round pipe, translating into 15 % lower kWh consumption for residential and commercial HVAC units .

Product Features

Aluminum Microchannel Tube 1-220 mm Wall

We continuous-seam-weld 3003-modified or 6063-T5 billet through a 12 000-ton porthole press, maintaining ≤±0.02 mm wall tolerance and ≥6 MPa burst pressure even at the 220 mm ultra-thick corner.

Every coil passes 2.5 MPa helium leak test (<1×10⁻⁹ Pa·m³/s) and 1 000 h neutral salt-spray to ASTM B117, ensuring 15-year field life in coastal or polluted environments .

Typical outer dimensions span 10 mm–220 mm width × 1.2 mm–30 mm height; channel count 3–90, hydraulic diameter 0.4 mm–8 mm.

Options include zinc-spray 5–25 g/m², chromate-free flux coating, or internal rifling for super-critical CO₂ heat-pump systems.

Supplied straight (3/6 m), LWC (≤300 kg), or CNC bended to ≤0.5×tube height radius without crack

| Item | Range |

| Tube length | 20mm-6000mm |

| Tube width | 10mm-220mm |

| Tube height | 1.2mm-30mm |

| Wall thickness | 0.15mm-0.6mm |

| Alloy | 6061 1100 3003 3102 |

| Temper | O HO H112 |

| zinc spraying | 5g/㎡-15g/㎡ |

Product Applications

1. EV thermal management: battery cold plate, chiller, power-module baseplate

2. HVAC-R: R290/R32 microchannel condenser, evaporator coil

3. Energy storage: liquid-cooling plate for 280 Ah LiFePO4 pack

4. Industrial: inverter heat sink, wind-turbine transformer cooler

Aluminum Microchannel Tube 1-220 mm

OEM aluminum microchannel tube 1 mm-220 mm thickness, multi-hole extrusion, ≤±0.02 mm tolerance. Boost HVAC heat-transfer 30 %, cut energy bill 15 %. • Have good experience working with big customers all over the world; • Free samples are available to give a quality check; • Cost-effective; • Fast delivery time; • Good communication skills to provide good service and understanding to customers. Welcome to Place Your Professional Order

Product SKU: 99999

Product Brand: DAG

5