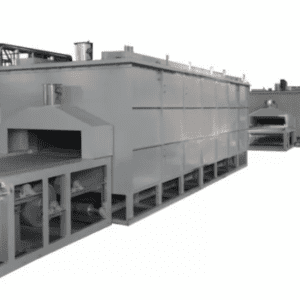

The aluminum atmosphere brazing furnace is an industrial equipment specifically designed for continuous brazing of aluminum alloy components (such as automotive radiators and air conditioning evaporators) under a protective atmosphere.

This brazing furnace operates under nitrogen atmosphere protection, utilizing non-corrosive flux to continuously braze aluminum heat exchanger products including radiators, oil coolers, intercoolers, heater cores, tube-and-fin condensers, evaporators, parallel-flow condensers, stacked evaporators, and power plant air coolers.

Equipment Introduction

The line is optimized for mass production of aluminum heat exchangers—parallel-flow condensers, laminated evaporators, engine radiators, charge-air coolers and battery cold plates—delivering hermetic, corrosion-resistant joints at automotive OEM throughput rates.

Purpose-built for high-volume, flux-assisted brazing of aluminum assemblies under a protective nitrogen atmosphere, the CAB furnace integrates:

1. High-precision flux spraying station

2. Electric pre-dry oven for flux fixation and moisture removal

3. Multi-zone radiant-heating brazing chamber with ±3 °C uniformity

4. Hybrid water- and forced-air cooling section for rapid, distortion-free cool-down

5. Closed-loop atmosphere control system delivering < 50 ppm O₂ throughout the process envelope

Application Areas

Automotive Parts: Brazing of all-aluminum heat exchangers such as condensers, evaporators, and intercoolers, replacing copper to reduce weight by 30%.

Power Plant Equipment: Brazing of air coolers and stacked evaporators, meeting the needs of handling large workpieces (1100 x 350 mm).

Electronic Cooling: Efficient welding of new energy battery liquid cooling plates and server cooling modules.

Aluminum Controlled-Atmosphere Brazing (CAB) Furnace

Aluminum atmosphere brazing furnaces are primarily used for brazing aluminum parts in a protective atmosphere. They consist of a flux sprayer, an electric drying furnace, a brazing heating furnace, water- and air-cooling devices, an atmosphere control system, and an automatic control system. They are suitable for mass production of aluminum radiators, such as parallel flow condensers, laminated evaporators, and automotive radiators. We can customize our products to meet your needs and budget at competitive prices. We welcome inquiries and look forward to establishing long-term partnerships.

Product SKU: 2

Product Brand: DAG

5