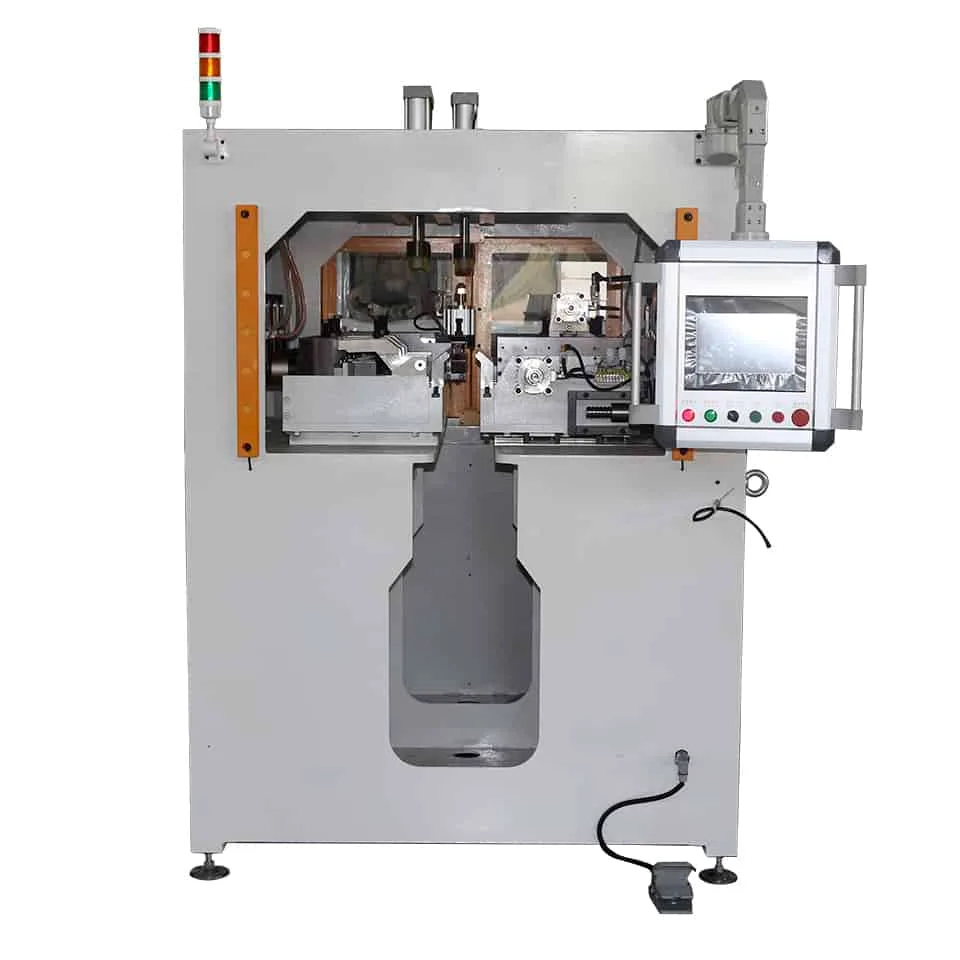

16M Aluminum Brazing Furnace Nitrogen Protective Atmosphere

Continuous CAB line engineered for high-volume brazing of aluminium intercoolers, radiators, A/C condensers, laminated evaporators and oil coolers. Nitrogen atmosphere ≤20 ppm O₂, three-zone temperature uniformity ±2 °C, belt speed 150–600 mm/min, flux recovery and rapid convection cooling deliver leak-free joints with minimal distortion. Modular 16 m footprint, expandable to 22 m.

| Machine Name: | Aluminium Radiator Brazing Furnace | Brazing Muffle Length: | 16M |

| Application: | Aluminum Radiators | Mesh Belt Speed: | 200-1400mm, Depending On Furnace Size |

| Rated Working Temperature: | 650 Degree Celcius | Drying Temperature: | 230 Degree Celcius |

| High Light: | continuous aluminum brazing furnace, furnace brazing equipment | ||

Technical Parameters

Aluminum Brazing Furnace Nitrogen Protective Atmosphere

| Model | Rated heating power | emperature | Working size (mm) | Brazing oven effective length | Total length | ||

| Degreasing Oven | Drying Oven | Brazing Oven | |||||

| DG-450-200-6M | Non | 50KW | 150KW | Brazing temperature: | 450×200 | 6m | 23.5m |

| DG-600-200-6M | Non | 60KW | 180KW | 630°C; | 600×200 | 6m | 23.5m |

| DG-800-200-6M | Non | 70KW | 210KW | 800×200 | 6m | 23.5m | |

| DG-1000-200-6M | Non | 85KW | 245KW | Drying temperature: 250°C | 1000×200 | 6m | 23.5m |

| DG-600-200-8M | 50KW | 70KW | 240KW | 600×200 | 8m | 37.7m | |

| DG-800-200-8M | 60KW | 85KW | 280KW | Degreasing temperature: | 800×200 | 8m | 37.7m |

| DG-1000-200-8M | 76KW | 108KW | 330KW | 180°C | 1000×200 | 8m | 37.7m |

| DG-800-200-11M | 85KW | 120KW | 380KW | 800×200 | 11m | 48.4m | |

| DG-1000-200-11M | 108KW | 150KW | 450KW | 1000×200 | 11m | 48.4m | |

| DG-1200-200-11M | 120KW | 170KW | 520KW | 1200×200 | 11m | 48.4m | |

| DG-1200-200-16M | 150KW | 220KW | 760 KW | 16m | 65.0m | ||

| DG-800-220-8M | 70KW | 85KW | 280KW | 800×220 | 8m | 38.9m | |

Note: The heating furnace (brazing furnace section of the heat of the treatment line) is 8m, 11m, 12or 16m long based on the productivity line required by the customer.

Continuous Aluminum Brazing Furnace

The aluminum radiator brazing furnace uses non-erosive brazing material under the nitrogen-protective atmosphere. The continuous aluminum radiator brazing furnace is applied to the brazing of aluminum intercoolers, radiators, automobile air conditioning condensers, evaporators, aluminum oil coolers, etc. Designed & manufactured by DAG Shenzhen—full customizable, affordable prices, global delivery, turnkey installation, inquiries welcome.

Product SKU: 2

Product Brand: DAG

5

Reviews

There are no reviews yet.