Machine Introduction

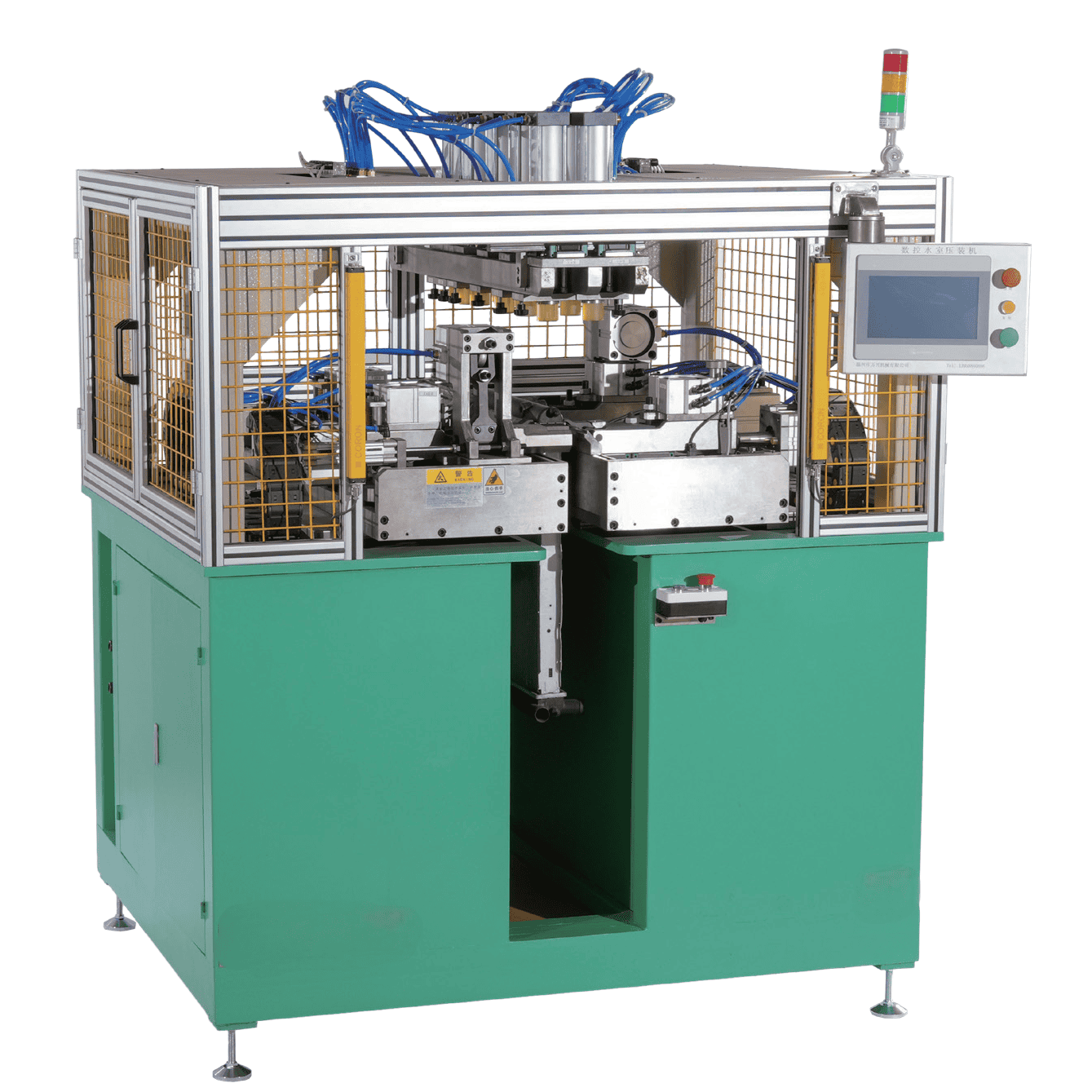

Automotive Radiator Plastic Tank Crimping Machine

This specialized crimping machine is engineered for automotive radiator manufacturing, designed to securely fasten plastic tanks, gaskets, and header plates into a sealed, leak-proof assembly. The equipment utilizes progressive pressure technology to sequentially crimp long and short side tabs within a single workstation, ensuring uniform sealing force and optimal structural integrity.

Key Technical Features

1. Progressive Single-Station Crimping: Simultaneously processes long and short side tabs with sequential pressure application.

2. Precision Sealing System: Creates reliable, airtight joints between plastic tanks and header plates.

3. High-Efficiency Design: Eliminates multiple workstations, reducing cycle time and maximizing throughput.

4. Multi-Product Versatility: Accommodates various radiator sizes and plastic tank configurations with minimal retooling.

5. Robust Industrial Construction: Built for continuous operation with low maintenance requirements.

Performance Benefits

✓ Superior sealing reliability and joint integrity

✓ Efficient single-stage processing reduces production time

✓ Consistent crimp quality across diverse product specifications

✓ Cost-effective solution for high-volume radiator manufacturing

Machine Parameters

Automotive Radiator Plastic Tank Crimping Machine

| Core height (distance between main boards) | 300mm-800mm |

| Core width (main board length) | 300mm-800mm |

| Core thickness (width of main board) | Under 32-80mm |

| Avoid the plastic tank nozzle travel | Less than 70mm |

| Compressed air pressure | 0.4mpa--0.7mpa(One stabilizing gas tank) |

| Storage | 500 kinds of water tank parameters,can arbitrary call |

| Power | Single phase 380 (V) |

| Dimension | L1700mm× W1600mm×H2100mm |

| Equipment weight | 1.7 (T) |

Automotive radiator plastic tank crimping machine for precision sealing. Features progressive single-station crimping, multi-product compatibility, and reliable performance for high-volume radiator manufacturing.

Car Aluminum Radiator Plastic Tank Crimping Machine

This specialized crimping machine is engineered for automotive radiator manufacturing, designed to securely fasten plastic tanks, gaskets, and header plates into a sealed, leak-proof assembly. The equipment utilizes progressive pressure technology to sequentially crimp long and short side tabs within a single workstation, ensuring uniform sealing force and optimal structural integrity. For detailed specifications, customization options, and competitive quotations, please submit your inquiry. We welcome your consultation and purchase orders.

Product SKU: 5

Product Brand: DAG

5

Reviews

There are no reviews yet.