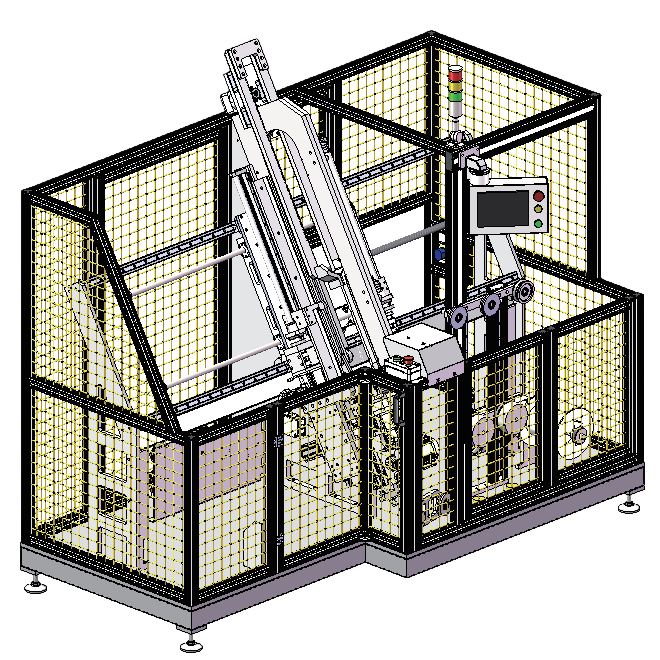

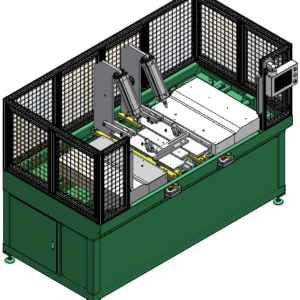

Machine Introduction

Radiator Core Wire Bandling Machine

This machine is used for the automobile condenser, the radiator core binding, the equipment is servo as the main power, the cylinder is the auxiliary power, the motion mechanism adopts the guide rail auxiliary, and the electric control system uses the motion controller. The number of core body wire channels is in the range of 1-5 channels. The binding position, number of tracks and core size can be realized in the setting program. The binding strength is controlled by torque control, which can realize the independent torque setting of each track.

The equipment operation is simple, small area, high equipment operation accuracy, stable performance, and can adapt to multi-specification model production.

Key Features

1. 1.0 kW servo motor provides main tension; pneumatic cylinder assists strap feed and cut-off—low energy, low noise.

2. Linear guideway slide guarantees ±0.1 mm strap placement accuracy across 250–1 200 mm core widths.

3. Programmable HMI: strap position, pitch (20–300 mm), number of straps (1–5) and individual torque values (1–10 N·m) stored per part number; recipe change < 30 s.

4. Real-time torque transducer with closed-loop feedback; automatic re-tension if deviation > ±3 %.

5. CE/UL safety light-curtain, two-hand start, quick-change strap magazine; 99 % uptime demonstrated in 24/7 lines.

Customization & Logistics

1. Strap width, feed length and tension profile adapted to your core specification.

2. Remote FAT, multilingual manual, on-site commissioning, global spare-parts hub.

3. Export plywood crate, Incoterms FOB/CIF/DDP, 6-week lead time.

Machine Parameters

Radiator Core Wire Bandling Machine

| Core height (distance between main boards) | 300mm-800mm |

| Core width (main board length) | 200mm-800mm |

| Core thickness | 16mm-64mm |

| The number of wire | 1—5 wire |

| One action cycle time | ≤12S |

| Compressed air pressure | 0.4mpa--0.7mpa |

| Power | 380 V、20A |

| Dimension(L×W×H) | 2200mm×1200mm×2500mm |

| Equipment weight | 1(T) |

Radiator Core Wire Bandling Machine for Sale

Radiator core wire bandling machine is a special equipment for automobile condensers, radiators and evaporator cores, which can prevent deformation during brazing and core bundling. The equipment is easy to operate, easy to adjust and highly efficient. It is suitable for small and medium batch continuous production. Tailored to Your Specs, Affordable Price, Shipped Worldwide. DAG Worldwide Radiator Machinery Exporter. Get a Quote Now!

Product SKU: 5

Product Brand: DAG

5

Reviews

There are no reviews yet.