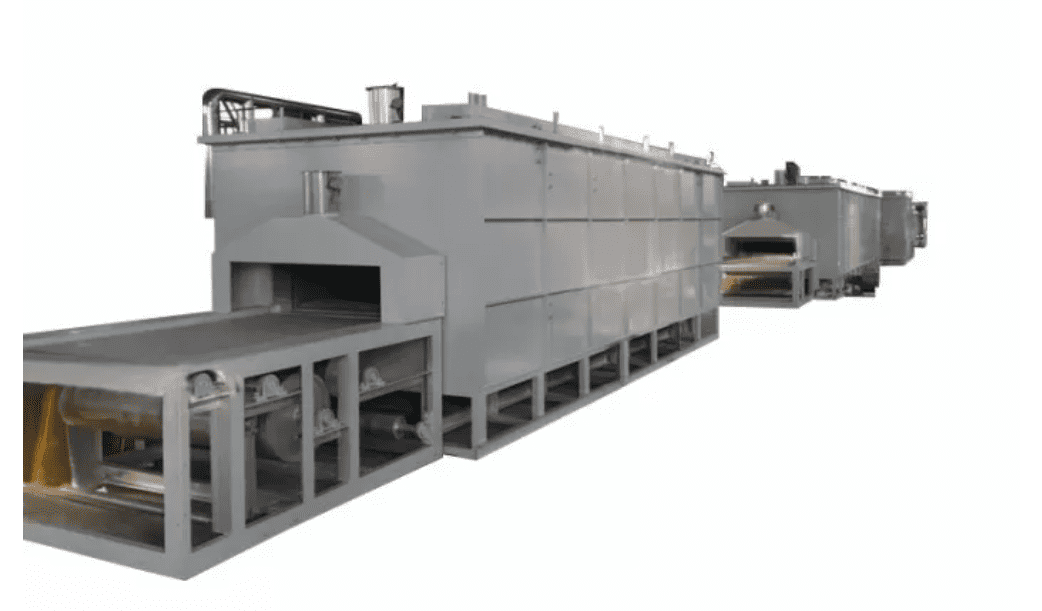

Controlled Atmosphere 650 Degree Aluminium Radiator Brazing Furnace

It consists of mesh belt conveyor systems, heating, cooling, and electric control; objects can be brazed: aluminum heat exchangers such as radiators, intercoolers, condensers, evaporators, and heaters.

| Machine Name: | Aluminium Radiator Brazing Furnace | Mesh Belt Speed: | 200-1000mm Per Minute |

| Brazing Area Length: | 8m | Rated Working Temperature: | 650 Degree Celcius |

| Protective Atmosphere: | Nitrogen | Warranty: | 1 Year |

| High Light: | continuous brazing furnace, 650 degree Aluminum Brazing Furnace, furnace brazing equipment | ||

Technical Parameters

| Mesh belt operation surface height | 850mm |

| Mesh belt speed | 300~800mm/min (inverter control) |

| Effective working size | 1000mm(width)×200mm (height) |

| Drying oven effective size | 5000mm(L)×1000mm(W)×200mm(H) |

| Brazing oven effective size | 8000mm(L)×1000mm(W)×200mm(H) |

| The overall dimension of the production line | 30700mm(L)×2050mm(W)×2100mm(H) |

| Total heating power | 450KW (120KW for drying oven and 330KW for brazing oven) |

| Power at temperature rising stage | 100% |

| power at the brazing stage | ≤60% |

| 99.999% nitrogen supply | 200m3/h (actual consumption:70-90m3/h) |

Product advantages

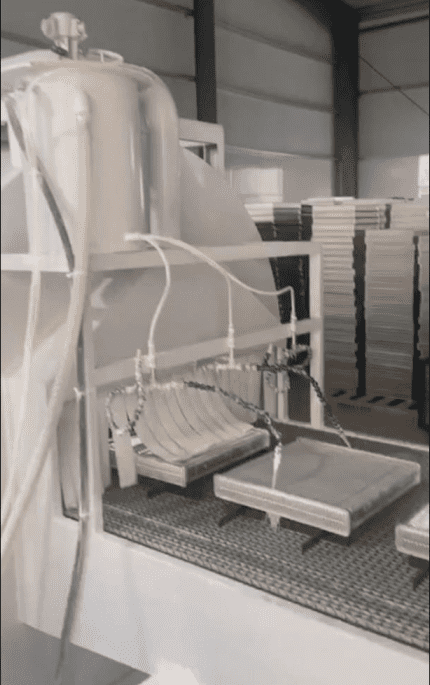

1) Driving system of mesh belt: The stainless steel roller is driven with high-temperature resistance through the chain wheel to circulate the mesh belt into the chamber, which can expand the mesh belt’s service life and reduce furnace heat loss while improving thermal efficiency.

2) The furnace was equipped with a fan to ensure uniform temperature and protect the evenly dispersed (carburizing) atmosphere, improving the carburizing speed and workpiece quality.

3) On the rear of the furnace, equipped with an exhaust fan for timely discharge of waste gas, improved the workpiece surface gloss.

4) The bottom of the furnace body is equipped with a slag removal mouth, which is convenient for cleaning up the slag.

5) The new sealing design of the furnace door can save 55-65% of atmosphere consumption, deep permeation, and 30-40% higher efficiency than before under pressure at ≥10-100Pa.

This mesh belt conveyor, aluminum and brazing furnace for radiator core, can be used to manufacture copper and aluminum radiator cores. By adjusting the temperature, it can also braze steel, iron, cameras, mics, and s. Power sources can be electricity or natural gas; please let us know your requirements.

If you are interested in setting up a radiator factory or buying any products at your place, please contact us. We will provide you with the best service and the best price.