Machine Description

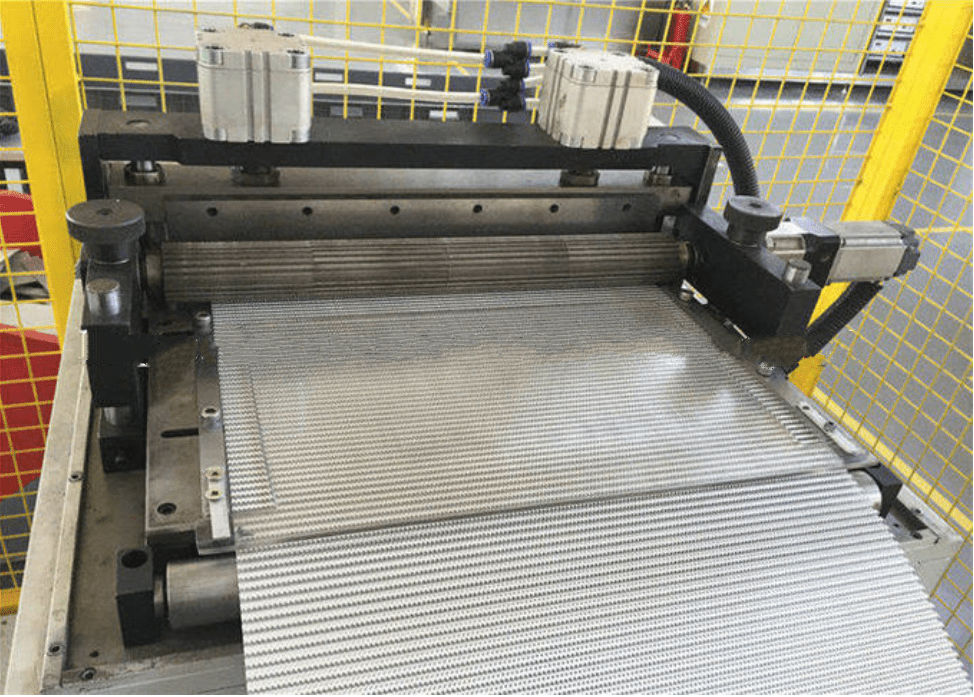

Aluminum Radiator Fin Stamping Machine

The aluminum radiator fin machine, also known as a fin stamping machine, is engineered for versatile, high-speed production of diverse fin patterns including straight fins, flat fins, serrated fins, perforated fins, wavy fins, louver fins, and other custom profiles for heat exchanger applications.

| Name: | Radiator Fin Machine |

| Max Fin Width: | 300mm |

| Fin Height: | 45 Mm |

| Weight: | 2000kgs |

| Size: | 1800*1000*2000 |

| High Light: | Fin press machine, flat fin machine |

Key Features & Highlights

1. High-precision fin press for flat fin production

2. Servo-driven positioning for superior cutting accuracy

3. Quick-adjust combined-width forming rollers reduce changeover time

4. Micro-spray lubrication system for optimal forming quality

5. Fully customizable specifications available

6. Decoiling, tensioning, feeding, forming, straightening, and cutting integrated

Technical Parameters

3003 Aluminum Foil Radiator Fin Machine for 45mm Height with Stable Performance.

| Machine Technical Parameters | Power supply | customized 3P five-wire |

| Fin height: 45mm Fin pitch: 8F | ||

| Punching force | 4200kg | |

| Fin Size | Fin Width | max 300mm |

| customized | ||

| Fin height accuracy | +/-0.01-0.05mm | |

| Overall Size | L, W, H | 1800*1000*2000mm |

| Total Weight | 2000kg | |

Components List of 3003 Aluminum Foil Radiator Fin Machine

| NO. | Item | Q’ty |

| 1 | Stamping Type Radiator Fin machine body | 1 set |

| 2 | Decoiler | 1 set |

| 3 | Lubrication device | 1 set |

| 4 | Servo cutter | 1 set |

| 5 | Collection table | 1 set |

| 6 | Toolbox | 1 set |

| 7 | Accessories | Several |

3003 Aluminum Foil Radiator Fin Machine

High-speed aluminum fin stamping machine for producing straight, flat, serrated, perforated, wavy & louver fins. Versatile fin forming solution for radiator and heat exchanger manufacturing. Quick-change die system available. Affordable Pricing. Fully Customizable. Welcome Your Inquiry.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.