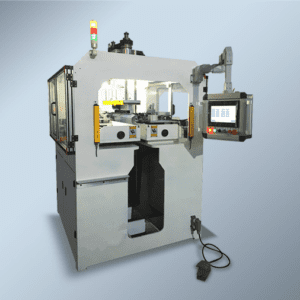

Machine Description

| Machine Name: | Radiator Plastic Tank Clinching Machine | Warranty: | 1 Year |

| Header To Header Distance: | 350-950mm | Header Length: | 100-800mm |

| Driving Force: | Servo And Pneumatic | Cycle: | About 25 Cores Per Hour |

| High Light: | radiator crimping tool,radiator tank crimping tool | ||

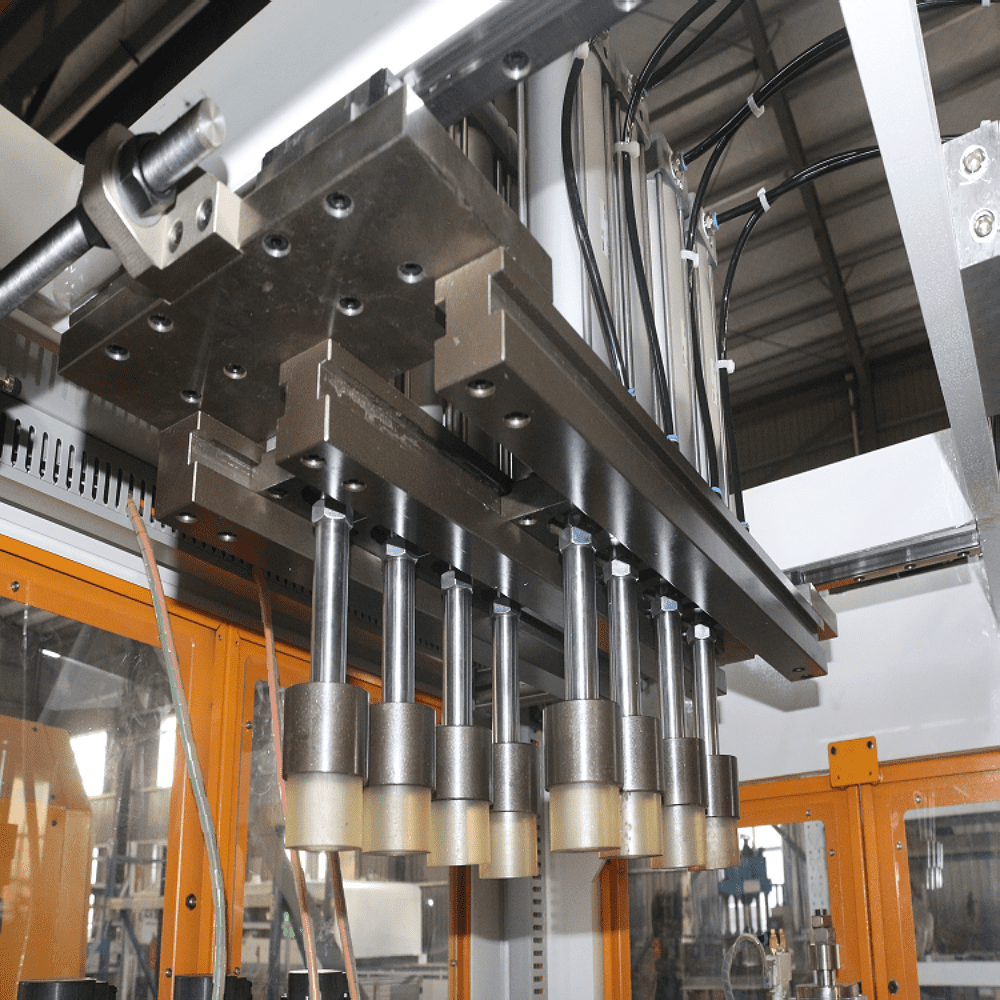

Radiator Plastic Tank Crimping Machine

Pneumatically-driven crimper forms uniform serrations on header-plate tabs, locking the plastic tank and gasket to the core and creating a leak-free seal. Ideal for automotive aluminum radiators and heavy-duty truck cooling modules.

Working Principle

1. Core & Tank Positioning

The pre-assembled radiator core (with header plates) and plastic tanks fitted with O-rings/gaskets are automatically loaded into the crimping fixture.

2. Pneumatic Clamping

Dual-action cylinders center and clamp the header-plate ears, ensuring zero movement during crimp formation.

3. Serration Forming / Tab Folding

Sequential or simultaneous crimping heads (shaped to the header-plate tooth profile) advance under regulated air pressure (0.5–0.7 MPa), folding each tab 90° ± 5° over the tank flange.

4. Controlled Compression

Adjustable stroke limiters and pressure regulators maintain uniform compression on the gasket, creating a metal-to-plastic interference lock without over-stressing the tank neck.

Machine Technical Parameters

| Item | Data |

| Header to header distance | 350-950mm |

| Crimping method | Stepping way |

| Header Width | 30-100mm |

| Suitable header plate length | 100-800mm |

| Production Capacity | About 25 cores/hour |

| Working Force | Servo+ pneumatic system |

| Machine dimension | 2100 x 1800 x 1800mm (L,W,H) |

| Machine weight | 2100 kgs |

| Working Power | 1.5 KW |

Aluminum Car Radiator Plastic Tank Crimping Machine

Radiator Plastic Tank Crimping Machine-Pneumatic cylinders drive the header-plate tabs over the plastic tank neck, compressing the gasket and locking tank to core in one cycle. This final assembly step guarantees a leak-proof coolant loop and finishes the radiator manufacturing process.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.