Radiator Core Builder Machine Manufacturer

DAG has been in automobile radiator manufacturing equipment for over ten years. We provide OEM and ODM, Non-standard customization services, solutions, and technical support. We are capable of doing everything.

Custom Radiator Core Builder Machine

DAG performed core builder machine OEM&ODM and provided non-standard customization services. Radiator core assembly machine, intercooler core assembly machine, multirow radiator core builder, radiator core builder (manual tube laying), and radiator core builder (auto tube laying, manual push tube storage rack) are among our equipment.

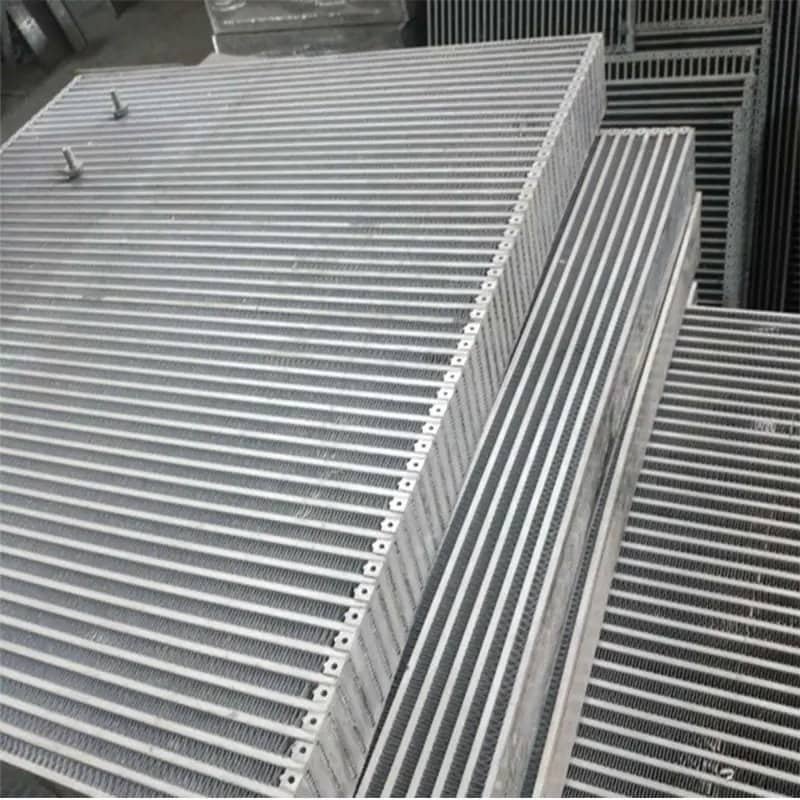

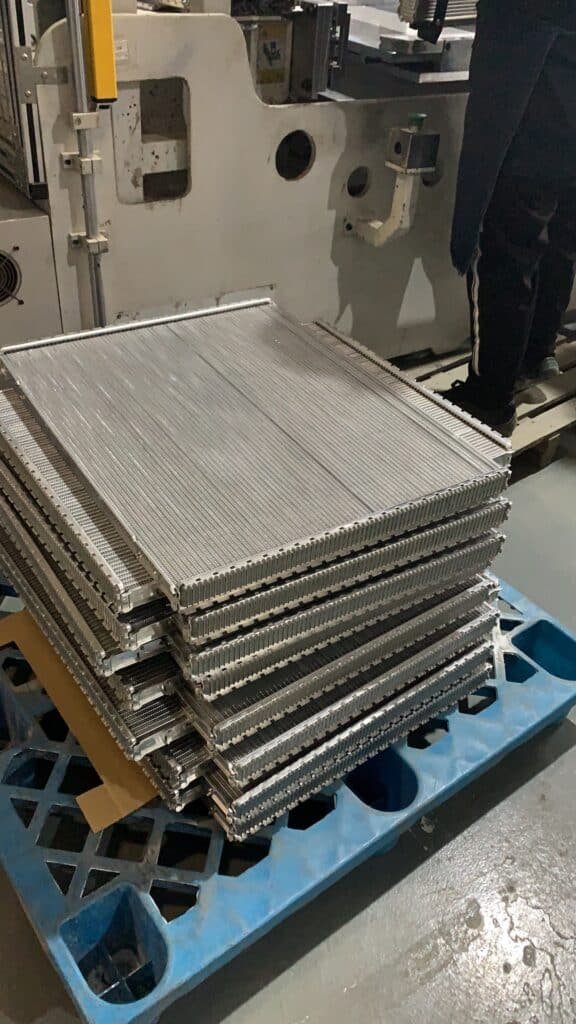

The core builder machine is able to assemble the header plate, side plate, fins, and flat tubes together as a core body. It has high assembly accuracy and a good appearance, which ensures a better brazing effect in the brazing furnace.

If you are interested in setting up a radiator factory in your place or buying any products, please get in touch with us, and we will provide you with the best service and best price.

Please fill out my online form.

Radiator Core Builder Machine By Features

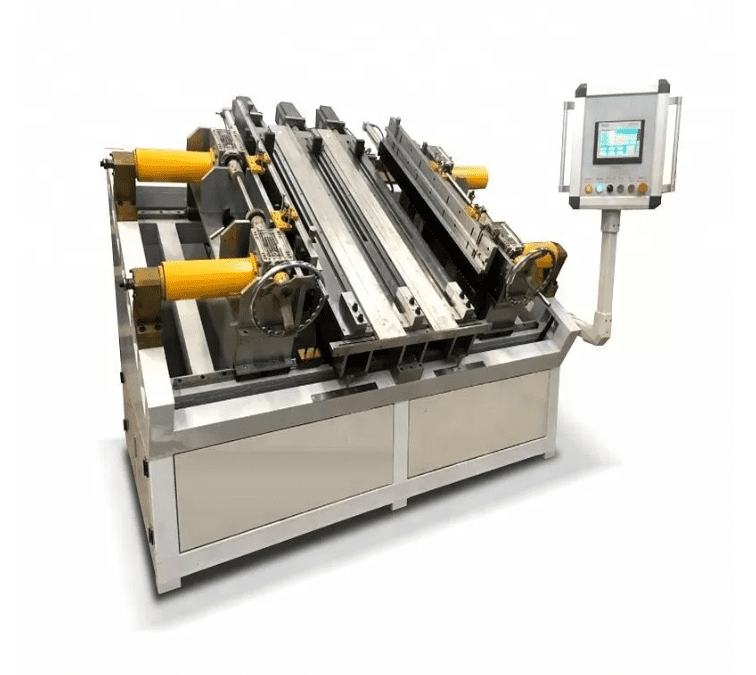

The 4-row radiator core builder machine has the advantages of stable and reliable working performance, easy operation, low noise, accurate positioning of flat tube center, and even distribution of fins.

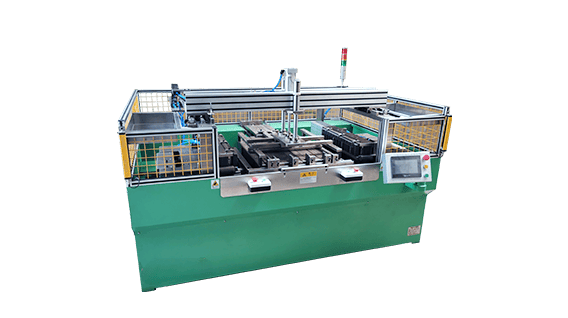

PLC-controlled intercooler core builder machine consists of a left and right header positioning fixture, tube end expansion device, tube storage box, tube distribution device, tube guidance device, tube guidance screw, assembling the working table, flat tube, and fin positioning device.

The radiator core assembly machine is used to assemble auto radiator cores. The machine has the advantages of stable and reliable working performance, easy operation, low noise, accurate positioning of flat tube center, and even distribution of fins.

The radiator core builder can assemble the header plate, side plate, fins, and flat tubes together as a core body. The core is then further brazed in the CAB brazing furnace. The core is well assembled, and the brazing quality can be assured.

The radiator core builder machine is used to assemble cores based on the combined control of a mechanical and pneumatic mechanism, the electrical control system of a PLC, and a touch screen. The flat tubes, fins, side plates, and header plates are manually placed on the work table.

Core-making machines include condenser core-making machines, intercooler core-making machines, heater aluminum core-assembling machines, and water tank core-making machines. They can adapt to different sizes of magnetic cores and be applied to different types of tubes.

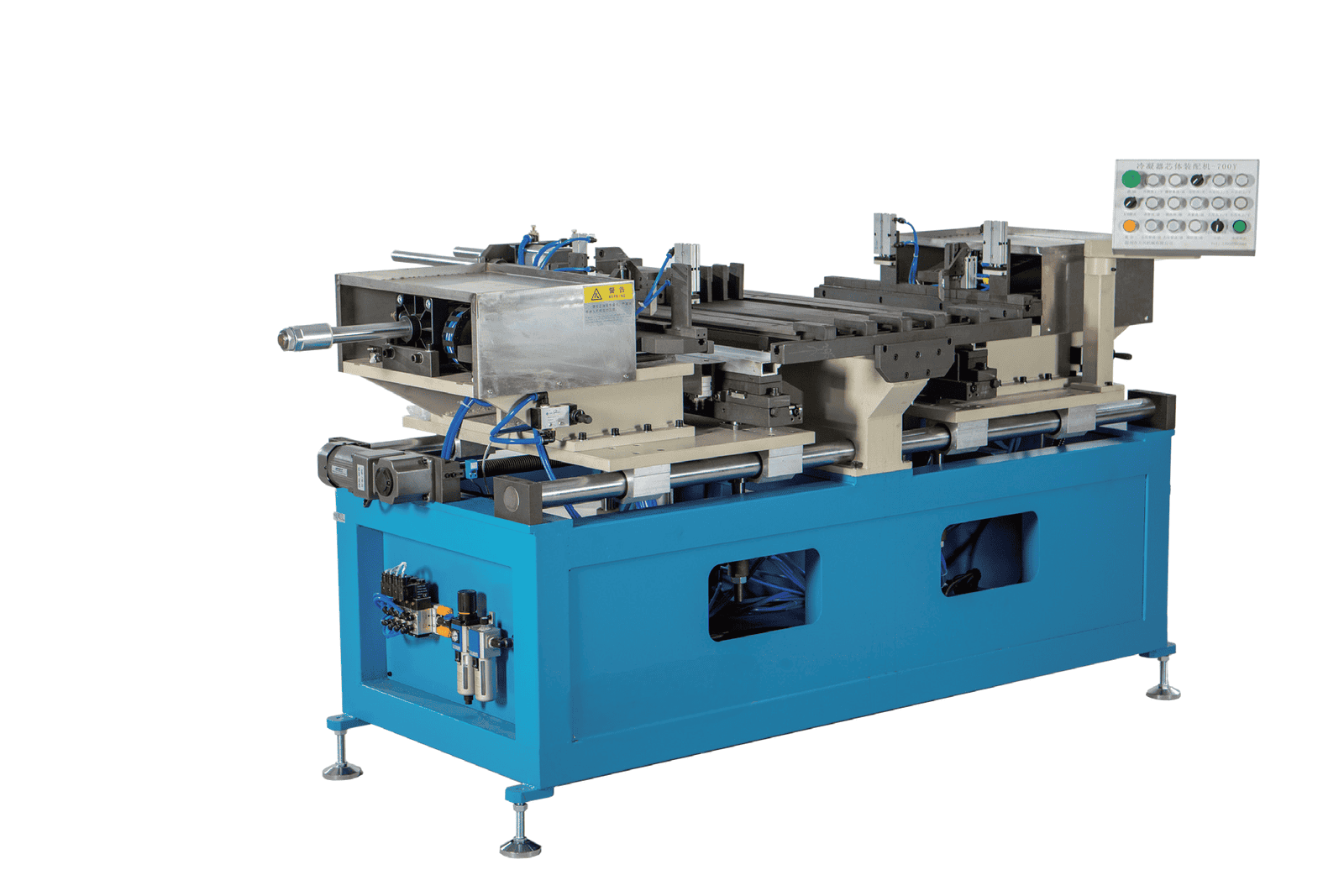

A hydraulic core assembly machine is used to assemble cores based on the combined control of a mechanical and pneumatic mechanism, the electrical control system of a PLC, and a touch screen.

The radiator core builder machine is used to assemble cores based on a combined control of a mechanical and pneumatic mechanism, the electrical control system of PLC, and the touch screen.

A radiator core builder machine is also called a radiator core assembly machine, aluminum radiator core assembly machine, or core assembly table. The assembled radiator core has a high assembling accuracy and a good appearance, which ensures a better brazing effect in the brazing furnace.

The equipment uses a servo motor for pressing power, a slide rail pair for the motion mechanism, a precision aluminum profile for the laying plate, a manual domino tube laying mechanism, a chain comb and a formed material needle combination. The equipment has a flat tube expansion function and a movable pressure cover.

The power of the machine is controlled by the cylinder, the process structure adopts the guide rail, and the position structure adopts the electrical equipment and machinery. The machine has the advantages of high process precision and high positioning accuracy. Simple operation, fast, safe, reliable, suitable for many variety of products.

This machine is used for the assembly of automobile radiators. Its main features are convenient and fast material distribution and simple use and adjustment. Compared with the fully automatic automobile heater assembly machine, this equipment eliminates the complex automatic material distribution device, and since it does not require flaring and adopts pneumatic transmission, the equipment price is greatly reduced.

Advantages of Core Builder Machine

Stability

The advantages are stable and reliable working performance, easy operation, low noise, accurate positioning of flat tube center, and even distribution of fins.

Customization

OEM and ODM services, Non-standard customization, factory direct sales, high quality and low price, multiple model options, and on-time delivery.

Economical

We provide a professional team with detailed solutions for free, saving you time and money and allowing your business to increase.

service

Contact us 24×7 to answer all your questions anytime, improve your work efficiency, and allow your project to proliferate.

Why Choose DAG to Customize Radiator Core Builder Machine

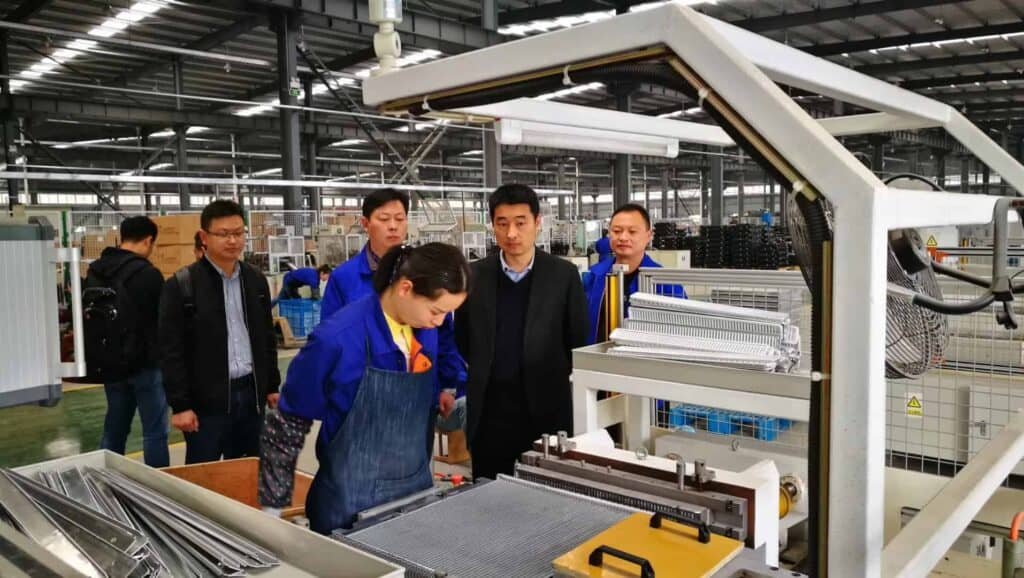

DAG provides a full range of automotive radiator production equipment. In its nearly twenty-year business career, it has accumulated rich production experience, and most of its equipment is sold in various countries and regions worldwide.

We provide customers with pre-sales and after-sales equipment design and services according to the size of the product. We will send technicians on-site to guide the installation to ensure smooth production at the customer’s factory and provide free consulting services without any problems during production.

To learn more about DAG radiator equipment capabilities, contact us or request a quote today.

Example of Display Results

People Also Ask

Q: What products can your radiator core builder machine produce?

A: Our assembly machine can produce radiators, condensers, and intercoolers. We can customize the machine according to your needs.

Q: What is the maximum size of the radiator produced by your assembly machine?

A: Our maximum assembly size is L1800 * W1200 * T56mm. We can customize the machine to your size.

Q: Can fins of different heights be assembled on the same radiator core builder machine?

A: The core machine can only assemble cores with a single fin height. We must customize fins of different heights if you need to assemble them.

Q: Is it possible to assemble fins of the same height in the radiator core and condenser core on the same radiator core builder machine?

A: No, because the radiator and condenser pipes are very different and cannot be mixed.