Choosing the right automobile radiator making machine helps save money and work faster in the radiator business. Companies need to pick a machine that fits their needs, budget, and radiator types. The table below shows how the right machine makes radiators better, look nicer, and get made faster while saving money:

| Advantage Category | Impact on Production Efficiency and Cost Savings |

|---|---|

| Improved Heat Dissipation | Even coatings help radiators work better and stop problems. This lowers the cost of fixing mistakes. |

| Enhanced Corrosion Resistance | Special coatings make radiators last longer. This means less money spent on repairs. |

| Improved Appearance Quality | Machines make sure every radiator looks the same. This cuts down on mistakes and saves materials. |

| Environmental Protection | Powder coating does not release harmful gases. It can be recycled, so there is less waste and lower costs. |

| Increased Production Efficiency | Machines work faster, so people spend less time working. This saves money. |

DAG gives Radiator Making Machine solutions with good quality, custom choices, and help when needed. Buying a machine that fits your radiator line gives you value for a long time, steady quality, and dependable work.

Key Takeaways

- Pick a radiator making machine that matches how much you want to make. Make sure it fits the types of radiators you need. Check if it fits in your workspace. This helps you work better and faster.

- Choose machines that work with your materials, like aluminum or copper. This helps you make good radiators and gives you more options.

- Find machines that are very accurate and fast. Automation helps you make more radiators and keeps the quality the same.

- Safety features and simple controls keep workers safe. They also help stop mistakes when using the machine.

- Good support after buying, like training and spare parts, helps your machine last longer. It keeps your machine working well.

- Make a careful budget. Think about the price, maintenance, energy costs, and ways to pay.

- Look at what people say about the supplier. Check reviews to find companies you can trust for good machines and service.

- Install the machine the right way and test it often. This makes sure your machine works well and makes strong, leak-free radiators.

Production Needs

Volume

How many radiators you make affects your machine choice. If you want to make a lot, you need a machine that works all the time and is fast. Big factories use machines that run by themselves to keep up with orders. Smaller companies might pick machines that need some help from people. These cost less and can do different jobs. The best machine helps you build radiators without stopping a lot. It also keeps work moving. Managers should figure out how many radiators they want to make each day and month. This helps them pick a machine that is fast enough and big enough for their needs.

Product Types

There are many kinds of automobile radiators. Most companies make tube-and-fin radiators because they are easy and cheap. Plate-and-fin radiators are used in race cars and big trucks. They are small and cool better. Brazed aluminum radiators are light and do not rust easily. They are used in fancy or fast cars. Crossflow radiators move coolant sideways and are good for new cars. Downflow radiators move coolant up and down and are found in old cars. What the radiator is made of is important too. Most new cars use aluminum radiators because they are light and cool well. Copper and brass radiators are heavy and mostly used in old or big vehicles. Some radiators use both plastic and aluminum to save weight and money. Companies should look at what kinds of radiators they want to make. They need to pick a machine that can handle all those types and materials. This makes sure the work goes smoothly and the radiators are always good.

Tip: Write down every radiator type your company wants to make. Make sure the machine you pick can work with each kind and material.

| Radiator Core Type | Description | Typical Applications |

|---|---|---|

| Tube and Fin | Tubes hold coolant, fins are around them | Most regular cars |

| Plate and Fin | Coolant goes between flat plates | Race cars, trucks |

| Brazed Aluminum | Light and does not rust | Racing, fancy, fast cars |

| Crossflow | Coolant moves sideways | New and changed cars |

| Downflow | Coolant moves up and down | Old and classic cars |

Facility Space

How much room you have changes what machine you can buy. Big machines need lots of space and clear paths for moving parts. Small shops may need smaller machines or ones that can be moved around. Companies should measure their space before buying a machine. Good planning stops things from getting crowded and keeps workers safe. Some machines can be set up in different ways or stacked. This helps you use your space better if you do not have much room. Managers should also think about where to put supplies, finished radiators, and space for fixing machines.

Radiator Making Machine Types

Automobile radiator making machines have different types. Each type does a special job in making radiators. Picking the right machine helps work go faster and makes better radiators. DAG sells many machines, like core builder machines, fin forming machines, and crimping machines. Each machine works for different radiator shapes and how many you need to make. The table below shows the main machines used to make radiators:

| Machine Type | Description / Features |

|---|---|

| Radiator Core Builder Machines | Manual, semi-automatic, and automatic choices; put radiator cores together; pick one based on your factory size and how many you want to make. |

| Radiator Fin Forming Machines | Automatic controls; make fins the right size; work with aluminum and copper; help heat move better. |

| Radiator Crimping Machines | Used for crimping plastic tanks; teeth can be changed; fits different core heights; speed is not always the same. |

Core Builder Machine

The core builder machine is very important in making radiators. It puts together the main parts of the radiator core. These parts are header plates, side plates, fins, and flat tubes. Workers put each part on the table. The machine uses moving parts and air power, with computer controls and screens, to press and line up the parts. This makes sure every radiator core has the right space and lines up well.

A good core builder machine helps keep the parts in the right place. It makes the core look neat, which is needed for the next step. The machine uses jigs to hold parts and sensors to find mistakes. New core builder machines can change fast for different radiator shapes. They use motors to control speed and pressure. This helps keep the fins and tubes lined up.

Factories can pick manual, semi-automatic, or automatic core builder machines. Small shops use manual machines for small jobs. Medium companies use semi-automatic machines for more speed. Big factories use automatic machines for fast and steady work. The right core builder machine works for many radiator types and can change as you need.

DAG’s core builder machine is easy to use, quiet, and puts parts in the right spot. The machine gets the core ready for brazing by spreading fins and putting tubes in the right place. Sensors watch the work and stop the machine if there is a problem. This stops mistakes and keeps the quality high. The computer lets workers change radiator shapes quickly, so the machine can do many jobs.

A good core builder machine helps work go faster and makes less waste. It checks the space and lines before brazing to keep quality good. DAG’s machine can put together a core in just one second for each fin and tube. This helps factories make lots of radiators. The machine works for both normal and special radiator shapes. Companies can ask for changes in fin height, width, and more. The right core builder machine makes sure every radiator is made well.

Note: Always pick a core builder machine that matches your work size and radiator types. This helps stop delays and keeps your factory working well.

Fin Forming Machine

The fin forming machine, or radiator fin machine, shapes the thin metal fins. These fins help the radiator move heat away. The machine stamps, folds, and cuts metal like aluminum or copper into the right fin shape. The fin machine uses computer controls and screens to set fin length, width, and thickness.

A radiator making machine line needs a good fin forming machine to keep up. The machine works with different metals, so it fits many radiator types. Workers can change the machine for fin heights up to 8mm. The machine keeps the size right within 3-5mm, so fins are always good.

The fin forming machine works fast, with some making up to 60 cuts each minute. This helps make lots of fins and saves materials. The machine can make 1-6 rows of fins, so it works for many radiator shapes. DAG’s fin machine is used for cars, heating, cooling, and factories.

| Feature/Parameter | Description/Benefit |

|---|---|

| Fin Height | Can be changed up to 8mm |

| Accuracy | 3-5mm precision |

| Maximum Cut-off Speed | Up to 60 cuts per minute |

| Rows | Makes 1-6 rows |

| Fin Style | Flat fins, can be changed |

| Power | 1.5Kw |

| Voltage | 380V |

| Cut-off Mode | Mechanical |

| Machine Size | 12606001100mm |

| Applications | Cars, heating/cooling, factories, electronics |

| Benefits | Faster work, better fins |

A good core builder machine works best with a good fin forming machine. Together, they help every radiator meet the right standards. DAG’s machines are easy to change, so they work for normal and special radiator jobs.

Crimping Machine

The crimping machine helps attach the radiator’s water tanks to the core. This machine uses strong power or motors to press the plastic or metal tanks onto the core. The crimping machine pushes evenly, so there are no leaks and the radiator stays strong.

Workers can change the teeth and how deep the press goes for different radiators. Sensors watch the work to make sure the seal is tight but does not bend the parts. The machine works with many materials and radiator sizes, so it fits many jobs.

Automatic features, like computer controls and cameras, help stop mistakes. The crimping machine can finish each press in less than 10 seconds. This helps factories make lots of radiators and keep them good.

A good core builder machine gets the core ready for crimping. The crimping machine then locks the parts together to keep them strong. DAG’s crimping machines work well and are easy to use, so they are a good pick for any radiator making line.

Tip: Check the crimping machine’s sensors and settings often. This helps stop leaks and keeps the radiator working well.

Brazing Furnace

A brazing furnace is very important in making radiators. This machine joins the core, fins, and tubes together. It makes the radiator strong and stops leaks. The furnace gets very hot and melts the solder. This sticks all the parts together. DAG sells brazing furnaces for both aluminum and copper radiators.

Controlled atmosphere brazing furnaces use nitrogen gas. This keeps oxygen low and stops rust. The furnace heats up fast and gets to about 680°C. The heat goes up by 50°C each minute. After heating, the furnace cools the radiator quickly. This helps the bond stay strong. The muffle and gas barriers keep the air inside clean. These things help make good radiators with fewer mistakes.

Vacuum brazing furnaces use a vacuum to take out air. This helps control the heat and makes better welds. The vacuum level changes how good the weld is. The furnace keeps the heat between the solder’s melt point and the metal’s solid point. The heat stays for about three minutes after it gets hot enough. This helps remove oxide and makes the joint strong. Cold wall vacuum furnaces use water to cool down. This saves energy and heats evenly.

| Model | Dimensions (mm) | Effective Height (mm) | Power Rating (KVA) |

|---|---|---|---|

| MES-NOC-500 | 500 x 2500 x 7000 | 150 | 230 |

| MES-NOC-750 | 750 x 5100 x 16000 | 150 | 450 |

| MES-NOC-1000 | 1000 x 8200 x 23000 | 150 | 750 |

Brazing furnaces follow safety rules like NFPA 86 and UL508a. The power needed depends on the size and how many radiators you make. DAG’s brazing furnace works with other machines in the line. It helps make sure every radiator is high quality.

Note: Always pick a brazing furnace that matches your work size and radiator type. This keeps your work safe and steady.

Specialized Machines

Specialized machines help factories make special radiator designs. These machines can handle different shapes, sizes, or cooling needs. DAG has many specialized machines for different radiator lines.

Some examples of these machines are:

- Genset radiator machines

- Remote radiator machines

- Frac pump radiator machines

- Hydraulic engineering radiator machines

- Machines for cranes and bulldozers

- Plate heat exchanger machines

- Industrial radiator machines for heavy equipment

Factories use these machines to make radiators for forklifts, air compressors, and more. They also work for welding equipment, engines, loaders, and boilers. Custom machines help companies meet special cooling needs. Some companies use 3D modeling and CAD software to design new radiators. Skilled workers use new brazing and welding ways to make sure each radiator is strong.

DAG’s specialized machines work with the core builder machine and others in the line. These machines help companies make special radiators for old cars, big machines, or tough places. You can change fin height, width, or add logos and labels.

Tip: Pick specialized machines if you need to make custom radiators or work in special industries. This helps you meet customer needs and be different from others.

Key Features

Precision

Precision is very important when making good radiators. Each machine must give exact results, especially when stamping aluminum fins. The holes in the fins must be spaced at 1.5 ± 0.01 mm. This small difference helps the radiator move heat away from the engine well. New machines use special roller feeders with anti-backlash systems. These systems keep the metal moving at the right length. They hold accuracy at ±0.01 mm, even when working fast. Keeping the holes spaced right for many cycles helps the radiator last longer and work better.

The metal must also stay flat. If it bends or has stress, the radiator can crack or warp. Synchronous leveling machines keep the metal flat and free from stress. This helps the machine stamp fast and keeps the surface smooth. The radiator ends up strong and without problems. Factories using precise machines make fewer mistakes and better products.

Speed

Speed helps factories make more radiators. A fast machine can shape, cut, and put parts together quickly. High-speed fin forming machines can make up to 60 cuts each minute. This helps factories fill big orders and not make people wait. The core builder machine also works fast, putting each fin and tube together in one second. Fast assembly means more radiators leave the factory every day.

Going fast does not mean the quality drops. Modern machines stay accurate even when working quickly. They use sensors and computers to check each step. If something goes wrong, the machine stops and tells the worker. This keeps the line moving without lowering standards. Companies with fast machines can do more work and grow bigger.

Automation

Automation changes how radiators are made in factories. Automated machines can run for many hours without stopping. They keep the line moving and help make more radiators each day. Automated systems feed molten aluminum or other materials into the machine. This steady flow keeps everything working smoothly.

Many factories use robot arms or ejectors to take out finished parts. This step means less work for people and saves money. Automation also makes things more exact and reliable. Machines with automatic controls make fewer mistakes and better radiators. Less hand work means higher standards and better efficiency.

Tip: Automation helps companies save both money and time. It also makes sure every radiator leaving the factory is high quality.

Material Compatibility

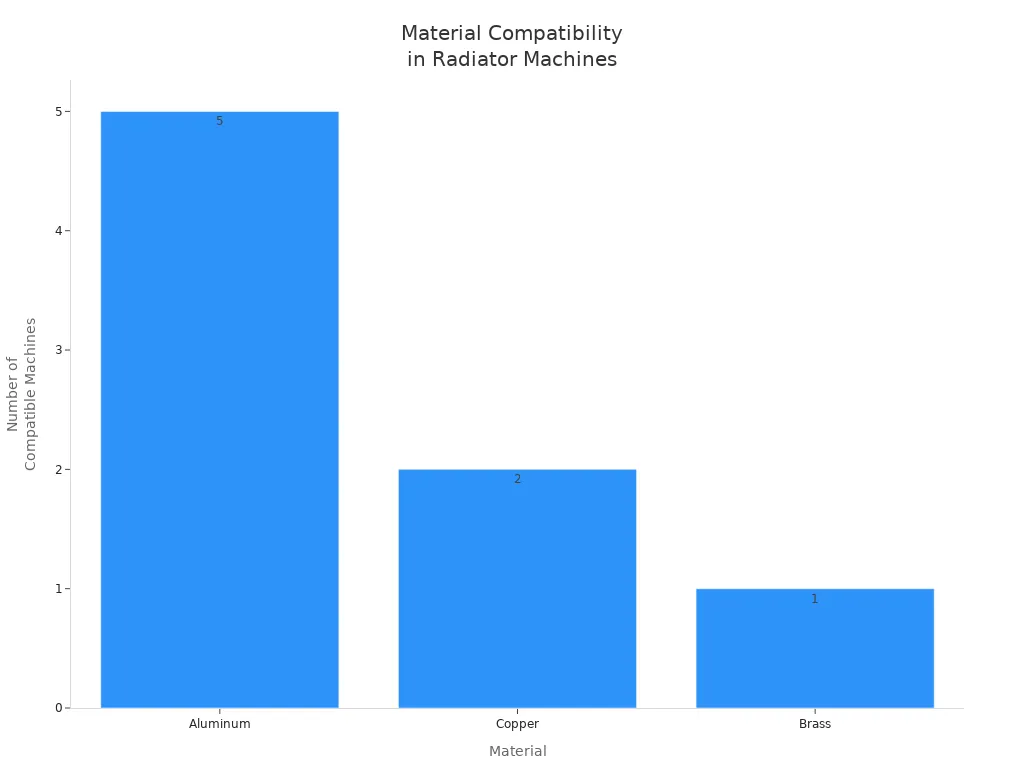

Material compatibility is very important when picking a machine for making radiators. The material you use changes how well the radiator works, how long it lasts, and how much it costs. Most radiator making machines can use aluminum, copper, or brass. Aluminum is the most popular because it is light, cools well, and does not rust. Copper and brass move heat well and are easy to fix, but they are heavier and cost more.

The table below shows which machines work with each material:

| Machine Model | Material Compatibility |

|---|---|

| DAG Radiator Making Machine | Aluminum, Copper |

| ZPX-280 | Aluminum |

| Hydraulic Core Machine | Aluminum, Brass |

| Automated Matrix Machine | Aluminum |

| Core Fin Radiator Machine | Aluminum, Copper |

Aluminum is still the best pick for most factories. It keeps radiators light and helps cool engines fast. Copper-brass radiators are good for big trucks and last a long time. A machine that can use both aluminum and copper gives companies more choices. This helps them make different radiators for many customers.

Note: Always check if the machine works with your material before you buy. This makes sure your radiator is good and does its job.

Energy Efficiency

Energy efficiency is important in today’s factories. A machine that uses less power saves money and helps the planet. Many radiator making machines now have better motors and smart controls. These help the machine use less energy while working. For example, machines with servo motors change speed and power for each job. This way, the machine only uses what it needs.

Some machines turn off by themselves when not being used. This stops wasting power and lowers the electric bill. Factories with energy-saving machines can make more radiators without spending more money. Using less energy also means the work area stays cooler, so workers are safer and more comfortable.

Tip: Pick a machine that saves energy. This helps your factory do better and is good for the environment.

Ease of Use

Ease of use makes it simple and safe for workers to run the machine. A good radiator making machine has easy buttons and clear screens. Workers can learn to use it fast, even with little training. This means fewer mistakes and steady work.

Some things that make machines easy to use are:

- Simple screens and easy buttons for quick use.

- Workers do not need much training.

- Smart controllers help the job go faster.

- The design makes it easy to use and fix, so there is less waiting.

- Semi-automatic machines need less hand work.

- Good help, like online guides, FAQs, and manuals.

- Service and repair help at the factory if needed.

A machine that is easy to use helps new workers start fast. It also lets skilled workers focus on doing a good job. DAG radiator making machines have these features to help factories work well.

Tip: Choose a machine with good help and simple controls. This keeps your radiator line working with fewer problems.

Safety

Safety is very important in any factory that makes radiators. Workers must be safe when using big machines. Companies should pick machines with good safety features to protect workers and keep work going.

New radiator making machines have many safety systems. These systems help stop accidents and keep work moving. Here are some common safety features in these machines:

- Emergency stop buttons close to where people work

- Safety covers over moving machine parts

- Sensors that find hands or things in risky spots

- Automatic shut-off if something goes wrong

- Warning lights and alarms to tell workers

DAG makes machines that focus on safety. Each machine has sensors to watch for unsafe moves. If a worker puts a hand in a moving part, the machine stops fast. This helps stop injuries. Safety covers hide sharp or hot parts. Workers can do their jobs without being scared.

Training is also important for safety. Companies should teach workers how to use each machine before they start. Easy instructions and clear signs help everyone remember safe steps. Checking and fixing machines often keeps them working well. Machines that are taken care of do not break and are safer.

Tip: Always look at safety features before you buy a radiator making machine. Good safety systems keep workers safe and help the factory run well.

A safe place to work helps everyone do a good job. When workers feel safe, they work faster and make better radiators. Companies that care about safety have fewer accidents and less lost time.

Quality and Reliability

Consistency

Consistency means every radiator is made the same way. Factories use careful planning and strong materials like aluminum and copper. These materials help radiator cores last in hard places. Special machines shape and put together each part with care. Workers and machines check each step for mistakes. Companies follow rules to keep quality high.

- Careful planning keeps radiator cores tough.

- Strong materials stop rust and handle heat.

- Special machines control fin shape and core size.

- Checks happen at every step of building.

- Factories use ISO9001 and TS16949 for trust.

When factories focus on consistency, every radiator works well. This helps customers trust the product and keeps work moving smoothly.

Testing

Testing is important to make sure radiators work well. Each machine helps test for leaks, strength, and cooling. Factories use many ways to test radiators before sending them out.

- Looking at the radiator finds problems and checks size.

- Pressure tests find leaks and test how strong it is.

- Rust tests show if the radiator can last in tough places.

- X-ray and sound tests find hidden problems inside.

- Cooling tests make sure the radiator cools as it should.

- Tube burst and solder spray tests check if joints are strong.

- Machines are checked often to keep tests correct.

Quality teams write down every test and save the results. Customer ideas help make better radiators next time. These steps make sure each radiator is strong and works well.

Note: Testing and checking often help stop problems and keep radiators working.

Machine Lifespan

How long a radiator making machine lasts is important. Factories pick machines with strong frames and good parts. Good aluminum and special metals stop damage and rust. Smart designs help moving parts last longer. Regular care keeps machines working well.

- Machines with PLC controls and servo motors last longer.

- Strong parts protect against daily use.

- Workers check and fix machines often.

- Factories clean and change parts on a schedule.

A machine that lasts a long time helps factories keep making radiators. Good machines mean less stopping and more work done. Spending money on strong machines saves money later.

Compare Machines

Technical Specs

When you look at radiator making machines, the technical specs are very important. Buyers should check some key features to make sure the machine is right for them. Here are the most important technical specs:

- Control systems like PLC and servo motors help the machine work well. They also make it easy to change settings.

- Energy-saving features, such as smart motors and idle modes, use less power. This helps save money.

- If the machine works with your other equipment, it will fit into your factory better.

- The machine should handle different radiator core sizes, fin types, and materials like aluminum or copper. This gives you more options.

- Machines can be manual or automatic. This changes how fast they work and how many people you need.

- Production speed and output volume tell you how many radiators the machine can make in a certain time.

- Precision features, like adjustable speed and built-in checks, help keep the quality high.

- Scalability means the machine can grow with your business.

- Safety features, such as light curtains and two-hand controls, help keep workers safe.

- Certifications and good supplier support make the machine more reliable and easier to fix.

Tip: Always look at these specs side by side when picking a radiator machine supplier you trust.

Supplier Reputation

A supplier’s reputation is important for getting good machines and help. Trusted suppliers like DAG have a history of making strong and steady machines. These companies make machines that are very accurate and can make a lot of radiators. They also let you change the machine for different radiator types and factory needs.

Good suppliers give 24/7 technical help, training, and repairs. This support helps you fix problems fast and keeps the machine working. Warranties from good suppliers protect you from broken parts and help you trust them. Friendly customer service, from buying to setting up, makes sure the machine works as it should. Always check if a supplier has a good reputation before you buy.

Customer Reviews

Customer reviews show what real people think about radiator making machines and their suppliers. Reviews talk about what is good and bad, so buyers can make smart choices. The table below shows what customers say about top brands:

| Brand | Strengths | Weaknesses |

|---|---|---|

| DAG | High automation, precision, reliability, 24/7 support, fast machines, OEM/ODM options | Warranty details product-specific |

| Atlas Radiator Inc | Fast shipping, spare parts, easy setup, training, good support | Longer delivery for custom machines |

| Radiator Supply House | Excellent customer service, quick turnaround, handles special orders | Limited product specs, no detailed warranty |

| Guangdong Faret Auto Radiator | Wide export network, strong supply chain, high customer satisfaction | Not enough public details on weaknesses |

| American Radiator | Broad product range, reliable support, fast shipping | Not enough public details on weaknesses |

Many customers like DAG for its high automation, fast work, and strong technical help. Users say the machine is easy to use and works well. Atlas Radiator Inc gets good reviews for customer service and training. Radiator Supply House is known for quick answers and handling special orders. Guangdong Faret Auto Radiator gets high marks for being reliable and making customers happy.

Note: Reading customer reviews helps buyers pick trusted radiator machine suppliers and avoid problems.

After-Sales Support

After-sales support is very important for radiator factories. Buyers want more than just a machine. They want help to keep their work going well. Good support helps every day and in the future.

Most buyers want help at any time. 24/7 technical support means someone can help, even at night or on weekends. If something breaks, fast answers help fix it quickly. Companies like DAG answer questions fast, usually in one day. This makes buyers trust them and keeps work moving.

Training is also needed. New workers must learn to use the machine safely. Suppliers give training with books, videos, or visits. Trainers show how to set up, use, and care for the machine. This stops mistakes and helps work go faster.

Spare parts and repair help are important. Machines work hard and parts can break. Good suppliers keep extra parts ready and send them fast. Some even pay for repairs during the warranty. This keeps machines working and stops long waits.

Warranties help buyers feel safe. A good warranty covers broken parts and mistakes from making the machine. It saves buyers from surprise costs. Most warranties do not cover normal use or mistakes when setting up. Buyers should read the warranty before buying. Knowing what is covered stops problems later.

Customization support is helpful too. Some factories want special features or their own logo. Suppliers like DAG help make machines fit these needs. This helps companies meet customer needs and be different.

Tip: Pick a supplier with strong after-sales support. Look for help all day, quick spare parts, easy training, and a good warranty.

A good support team knows a lot and answers questions clearly. Friendly service helps build trust for a long time. When buyers know they will get help, they feel good about their choice.

Budget Planning

Price Range

Automobile radiator making machines have many different prices. The price changes based on the machine type, how automatic it is, and how many radiators it can make. Manual machines cost the least and are good for small shops. Semi-automatic machines cost more but help make more radiators. Fully automatic machines cost the most but work the fastest and need fewer workers. If you want special features or a custom design, the price can go up. Most companies give quotes that match what each factory needs. It is smart to check prices from different sellers to get the best deal for your money.

| Machine Type | Typical Price Range (USD) |

|---|---|

| Manual | $10,000 – $30,000 |

| Semi-Automatic | $30,000 – $80,000 |

| Fully Automatic | $80,000 – $200,000+ |

| Specialized/Custom | Varies |

Note: Prices can change if the machine is bigger, has more features, or comes from a different place.

Cost of Ownership

Owning a radiator making machine costs more than just buying it. Companies need to think about other things that cost money over time:

- The first price you pay for the machine

- Money spent on workers and power to run it

- Costs for fixing and keeping the machine working

- How long the machine lasts and how often it breaks

- How much of the work is done by the machine itself

- If you can change the machine for special jobs

- How many radiators the machine can make

- Help after you buy, like spare parts and fixing help

Fixing and taking care of the machine can cost a lot. Running the machine, like paying for power, can cost even more. Good machines that come with help do not break as much and save money. Machines that do more work by themselves may cost more at first but save money later because they need fewer workers and make more radiators. Buying from a trusted company helps make sure the machine works well and you get help when needed.

Tip: Checking the machine often and fixing small problems early helps save money and keeps it working well.

Financing

Many companies use financing to help pay for new machines. There are different ways to help businesses buy a radiator making machine without paying all the money at once:

- Renting for a short time

- Renting for a long time and maybe buying later

- Paying for the machine in small amounts over time

- Leasing the machine and having a choice to buy it later

- Long leases that let you choose what to do at the end

- Flexible leases that let you return the machine at certain times

These choices help companies start making radiators without spending all their money right away. Businesses can pick the plan that works best for how much money they have and what they want in the future. Machine makers and banks often work together to give good deals and help.

Companies should look at all the ways to pay and pick the one that fits their needs and budget best.

Purchase Process

Contact Suppliers

A buyer needs to find good suppliers for a radiator making machine. They can look online, go to trade shows, or ask other companies for ideas. Many suppliers show their machines on their websites or in business lists. It is smart to pick suppliers who know a lot about radiators. Checking for certificates and reading what other customers say helps you know if the supplier is trusted. When talking to suppliers, buyers should write down questions to ask. These questions can be about machine types, how long delivery takes, and what help is offered. Sending a clear message helps the supplier know what the buyer wants. Good suppliers answer fast and give lots of information. DAG lets buyers contact them on their website and gives help with technical questions.

Tip: Write down every supplier you talk to and what they say. This makes it easier to compare later.

Request Quotes

After talking to suppliers, a buyer asks for quotes for the radiator making machine. A quote tells the price and gives details about the machine. The buyer should say what kind of radiator they want, how many they need, and any special needs. This helps the supplier pick the best machine for them. Suppliers usually send quotes by email. The quote should say the price, when it will arrive, how to pay, and what the warranty covers. Some quotes also list extra costs like shipping or setting up the machine. Looking at quotes from different suppliers helps buyers get the best deal. Buyers should check if the quote fits what they need. If something is not clear, they should ask more questions. Talking clearly helps both sides understand the deal.

Verify Quality

Before buying, a buyer should make sure the machine is good quality. They can ask for certificates, test results, or names of other customers. Some suppliers show videos or live demos of the machine working. This helps buyers see if the machine does the job right. Buyers can also ask for a sample radiator made by the machine. This shows if the machine makes the same thing every time. Going to the supplier’s factory lets buyers see how the machines are made and checked for quality.

A checklist for checking quality:

- Look at certificates and test results

- Watch videos or see the machine work

- Ask for sample radiators

- Visit the factory if you can

- Ask for names of other customers

Note: Checking quality before you buy helps stop problems later.

Installation

Putting in an automobile radiator making machine is a big step. It helps start the production line. Companies need to plan well so everything works right and lasts long. First, they must get the factory ready. Managers check if there is enough space for the machine and for workers to move. Clear walkways help move parts and finished radiators easily.

Before setting up, companies must make sure all utilities are ready. This means steady electricity, air for the machine, and good airflow. Skilled workers should be there to set up and run the machine. Training from the supplier, like DAG, teaches workers how to use the machine safely and correctly.

A good setup follows the machine’s plans and rules. The machine must fit the radiator’s design and how much it needs to cool. Many companies pick bar and plate construction because it is simple and easy to fix. Using all-aluminum parts makes the radiator light, cools well, and saves money.

Important steps for installation are:

- Look at the machine’s drawings and what the site needs.

- Put the machine on a flat floor so it does not shake or move.

- Hook up power and air as the maker says.

- Clean the machine and area before putting it together.

- Build the machine parts to the right size.

- Use the right brazing with strong aluminum and cladding to stop leaks.

- Clean well before and after brazing for good quality.

- Check every joint to make sure there are no leaks.

- Run test cycles to see if the machine meets heat and work goals.

- Pack finished radiators carefully so the fins do not get bent.

Quality checks are very important during setup. Inspectors measure sizes, check brazing, and look for leaks. If they find problems, they can fix them before making lots of radiators.

The supplier helps with any problems during setup and later. DAG gives help, answers questions, and trains workers to keep the machine working well. Companies should write down each step, test results, and when they do maintenance.

Tip: Planning well and following each step helps stop delays and makes sure the machine works right.

A machine that is set up well helps make radiators fast, keeps quality high, and lasts a long time. Companies that take time to install it right have fewer problems and better results for many years.

Picking an automobile radiator making machine takes good planning. Buyers need to find a machine that fits what they want to make, how good they want it to be, and how much they can spend. They should look at different machines, check if help is easy to get, and pick brands people trust, like DAG. Taking time to plan helps companies get the most for their money. Good machines keep the radiator line working and help cars stay cool.

Making smart choices now helps you build strong radiators later.

FAQ

What types of radiators can DAG machines produce?

DAG machines make radiators for cars, trucks, and big machines. They also work for air conditioning systems. These machines can build tube-and-fin, plate-and-fin, and brazed aluminum radiators. If you need something special, you can ask for custom features.

How long does installation take for a radiator making machine?

Most machines are set up in one or two weeks. The time depends on how big the machine is and if your factory is ready. DAG helps with setup and trains your team so you can start fast.

Can one machine handle different materials like aluminum and copper?

Yes, DAG machines can use both aluminum and copper. You can change the material by adjusting the settings and using the right tools.

What maintenance do these machines require?

Operators should clean the machine every day and check moving parts. Follow a regular schedule for maintenance. DAG says to inspect the machine each month and replace worn parts. Taking care of the machine helps it last longer.

Does DAG offer technical support after purchase?

DAG gives technical help all day and night. You can call the service team for help with setup, fixing problems, or repairs. DAG also sends spare parts and training guides.

How does automation improve radiator production?

Automation makes work faster and more accurate. Machines with automatic controls need less hand work. This lowers mistakes and helps factories make more radiators in less time.

What safety features come with DAG radiator making machines?

DAG machines have emergency stop buttons, safety covers, and sensors. These features keep workers safe and help stop accidents.

Can DAG customize machines for unique production needs?

Yes, DAG can change machines for special jobs. You can ask for different fin heights, widths, machine sizes, or your own brand. Customers can get special features to fit their needs.