Choosing the right radiator fin forming machine starts with knowing what you need. A business must make sure the machine’s output and features fit its radiator line. Each machine must work with the needed radiator fin types and materials. DAG gives advanced technology for many radiator uses. A good machine will make radiator quality better and lower downtime. It will also help the business grow. A manufacturer should also think about support and budget when picking a machine for radiator making.

Key Takeaways

- Pick a radiator fin forming machine that matches how much you need to make and the fin types you use. This helps make better products and work faster.

- Find machines with rollers and blades that can change. This lets you make many fin shapes and sizes for different radiators.

- Machines with automation, like PLC control and servo feeding, help you work faster. They also lower mistakes and save energy.

- Safety features like overload protection, emergency stops, and guards keep workers safe. These features help stop accidents from happening.

- Make sure the machine works well with your radiator core builder and fits in your factory. This helps your work go smoothly.

- Doing regular maintenance, having spare parts easy to get, and good training help the machine last longer. This also means less time when the machine is not working.

- Think about the total cost, like energy, repairs, and support, not just the first price.

- Pick a brand you trust, like DAG, for machines that work well. They also give good support, training, and help with upgrades.

Radiator Fin Forming Machine Basics

What Is a Radiator Fin Forming Machine

DAG is a trusted company that makes radiator fin forming machines. These machines bend metal foils into fins for radiators. The fin rolling part shapes the fins very carefully. Operators use a touch screen and PLC control to run the machine easily. These machines work with both aluminum and copper. They can make straight, serrated, perforated, wavy, and louvered fins. The machines form fins quickly and cut them with accuracy. You can change the rollers and blades to make different fin types and thicknesses.

Tip: Radiator fin forming machines help companies make fins fast and with great accuracy. This makes radiators better and helps factories work faster.

| Feature | Description |

|---|---|

| Working Principle | Fin rolling part shapes fins with care |

| Control Mode | PLC control makes the machine easy to use |

| Feeding Speed | Can go up to 120 m/min for fast work |

| Blade Options | Single or many blades let you pick fin shapes |

| Operation Interface | Touch screen makes it simple to control |

| Fin Material | Works with aluminum and copper fins |

Types of Radiator Fin Machines

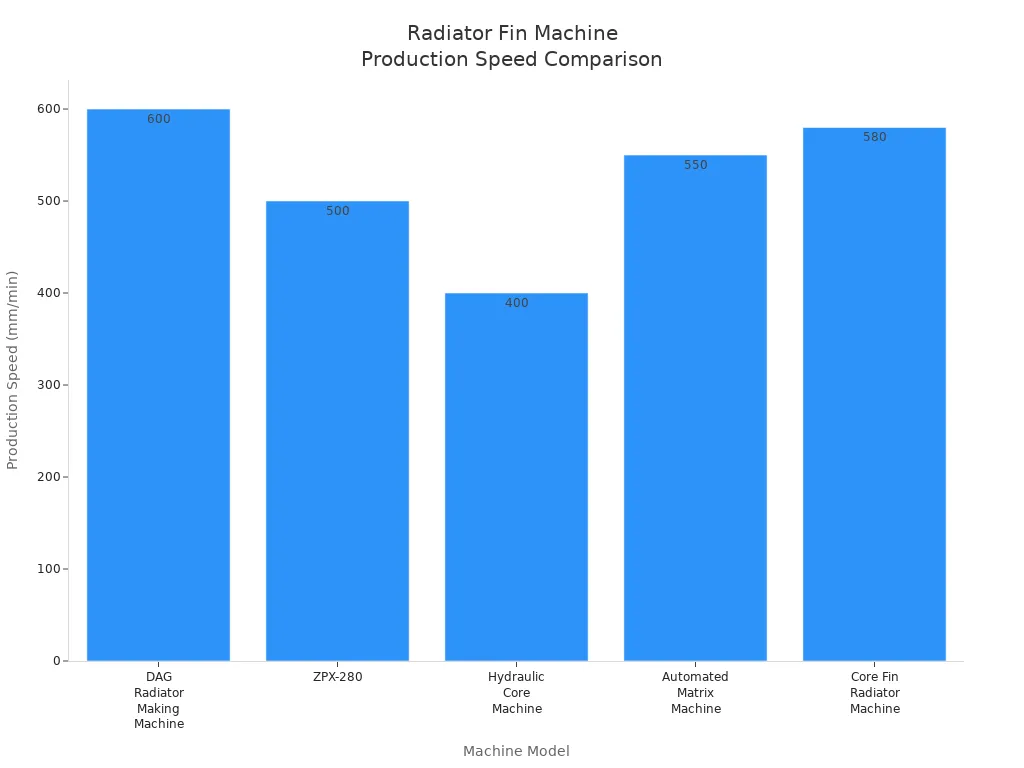

Different radiator fin machines are used for different radiator cores and products. DAG has machines for making both aluminum and copper fins. Fully automatic machines can go as fast as 600 mm/min and work with both metals. Semi-automatic machines are slower and good for smaller jobs. Some machines use hydraulic systems to build the core. Others use rollers to shape the fins. These machines can make fins for cars, air conditioners, and big industrial radiators.

| Machine Model | Automation Level | Production Speed | Material Compatibility |

|---|---|---|---|

| DAG Radiator Making Machine | Full | Up to 600 mm/min | Aluminum, Copper |

| ZPX-280 | Semi/Full | Up to 500 mm/min | Aluminum |

| Hydraulic Core Machine | Semi | Up to 400 mm/min | Aluminum, Brass |

| Automated Matrix Machine | Full | Up to 550 mm/min | Aluminum |

| Core Fin Radiator Machine | Full | Up to 580 mm/min | Aluminum, Copper |

Manufacturers pick a machine by looking at speed, what metals it works with, and if it fits with other machines. KL-Type machines are the fastest and work with many tube materials. L-Type machines are better for smaller amounts.

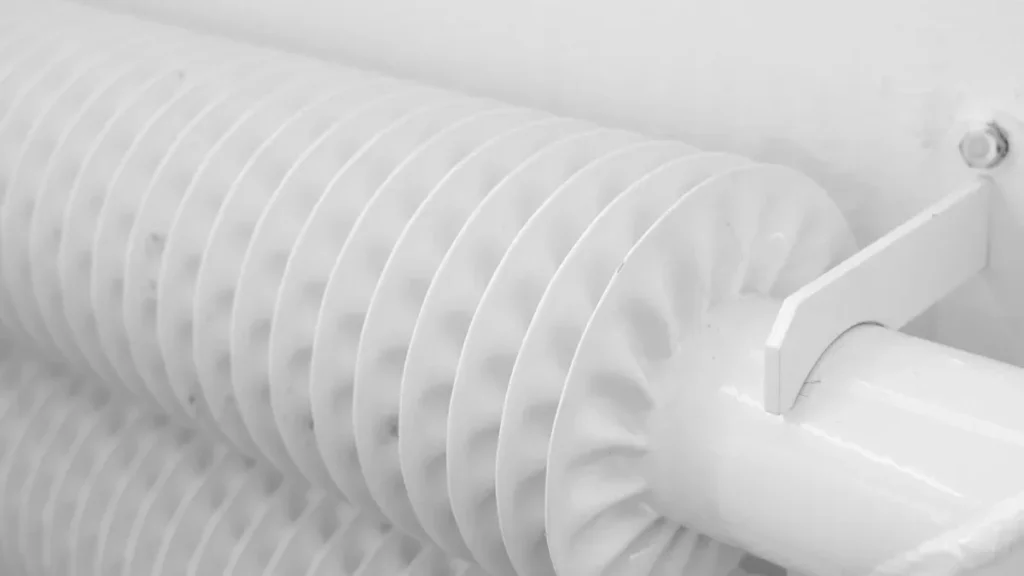

Applications in Radiator Production

Radiator fin machines are important in many fields. Car radiators use fins to move heat away from the engine. Air conditioners need fins in their coils to cool air. Big factories use fins in heat exchangers for power plants and chemical plants. The machines make fins that help cool things down by giving more surface area. Each fin design is made for its special job.

- Radiator fins act as heat sinks and move heat from coolant.

- Fins give more surface area so air can take away heat.

- Fins help hold the radiator tubes in place.

- Fin shapes help air flow and cooling for each radiator type.

DAG’s radiator fin machines work with both aluminum and copper. Copper machines handle thin copper foil and run fast. They use strong blades and can adjust for copper’s special needs. Aluminum machines use thicker foil and rollers to shape the fins. They can make louver, serrated, and flat fins. Both types cut fins accurately and the blades last a long time.

Radiator core builder machines work with fin forming machines to put radiators together automatically. This setup helps make more radiators and keeps quality the same. DAG gives solutions that make it easy to connect machines and make lots of radiators.

Production Needs

To pick the right radiator fin forming machine, you must know your production goals. Every radiator maker should match the machine’s size to how many fins they need, what types of fins they want, and their future plans. This part shows how to check how many fins you need, what kinds you want to make, and if you can grow your business later.

Output Volume

Manufacturers need to set clear goals before buying a machine. Output volume is how many radiator fins a factory makes in a certain time. Some factories need fast machines for big orders. Others need smaller machines for special or small jobs.

- Fast machines can make up to 60 meters of fins each minute.

- Small machines are good for shops that make fewer radiators.

- Factories should pick a machine speed that matches their needs.

A table can help compare different machines for different jobs:

| Machine Type | Output Volume (Fins/Hour) | Suitable For |

|---|---|---|

| High-Speed Automatic | 10,000+ | Large radiator factories |

| Semi-Automatic | 2,000–5,000 | Medium radiator workshops |

| Manual | <2,000 | Small radiator producers |

Tip: If you set clear goals, you can pick the best machine for making radiator fins and keeping them high quality.

Product Range

A wide product range helps radiator makers sell to more people. The right machine should work with many fin types and radiator shapes. DAG’s machines use rollers and blades you can swap out. This lets workers make straight, serrated, perforated, wavy, and louvered fins. You can also change the fin height and width. Factories can make fins from 8mm to 200mm wide and as thin as 0.07mm.

- Changeable rollers let you make many fin types on one machine.

- You can change fin sizes to fit different radiator designs.

- Factories can make fins for cars, air conditioners, and big machines.

- Radiator core builder machines can also be changed for different fin heights, so you can make more types.

Having many product choices makes radiators better and helps companies get new customers. Factories can keep up with what people want by making many kinds of radiators and fins.

Scalability

Scalability means you can make more radiators if your business grows. DAG’s machines come in many sizes, from small ones for new businesses to big ones for large factories. Some machines save energy for small lines, while others use more power for big plants.

- Small machines are good for little radiator shops.

- Big machines are best for factories that make lots of radiators.

- You can change dies quickly to make different fins, which helps you make many types.

- Factories can pick manual, semi-automatic, or fully automatic die changes, depending on what they need.

Semi-automatic machines are flexible and work well. Planning for growth helps radiator makers avoid spending too much later. Saving energy and picking the right size machine also helps when adding new machines to old lines.

Note: If you pick a machine that can grow with your business, your factory can meet new goals and keep making good fins as you get more orders.

Radiator Fin Machine Features

Precision

Precision is very important for radiator fin machines. DAG makes machines that shape fins the right way every time. The machine uses special rollers and blades to make fins the right size. Operators can set the fin height to about 8 mm. The machine can also make fins as thin as 0.07 mm. This matches what most radiator factories need.

The machine uses strong blades made with cobalt. These blades last through over 200 million fin bends. The machine can make fins up to 100 mm wide. This helps factories build many kinds of radiators. DAG’s machines use a micro oil spray system. This saves about 60% of the oil and keeps the machine running well. It helps make more fins and cuts down on waste.

| Parameter | Specification/Value |

|---|---|

| Working Speed | Up to 100 meters per minute |

| Fin Thickness | As low as 0.07-0.08 mm |

| Fin Height | Approximately 8 mm (±0.05 mm) |

| Fin Width | Up to 100 mm |

| Blade Service Life | ≥ 200 million fin convolutions |

| Lubrication System | Micro oil spray (saves ~60% lubricant) |

DAG’s machines let you change rollers for different fin shapes. You can make straight, serrated, wavy, or louvered fins. This helps factories make many radiator designs. The machine forms and cuts fins quickly and with care. Good precision keeps radiator quality high and lowers mistakes.

Tip: When fins are made with care, radiators work better and last longer. Good fin shapes help move heat and make radiators stronger.

Automation

Automation makes radiator factories work faster and easier. DAG’s radiator fin machine uses automation to speed up work and cut down on hand labor. The machine can make up to 100 meters of fin each minute. Operators use automatic feeding and cutting to keep things moving.

With automation, the machine can change fin types without stopping. It uses servo feeding and PLC control to set speed and position. This helps factories fill big orders and keep fins the same every time. Automation also lets workers change dies fast and start new jobs quickly.

- Automatic feeding keeps fin material moving all the time.

- Servo systems set fin position for each radiator.

- PLC control sets how fast the machine runs for each job.

- Quick die change tools save time and help workers.

- Automatic cutting keeps every fin the right length.

Automation helps factories save energy too. Motors only run when needed, so power use goes down. The machine uses hydraulic lifting and overload protection for safety. These features help stop delays and keep radiator making on track.

Control Systems

Control systems help run every part of the radiator fin machine. DAG uses smart control systems to make work easy and safe. The machine has a touch screen so operators can set fin size, speed, and type. PLCs and rotary encoders help the machine move the right way every time.

Modern machines use inverter speed control. This lets operators change motor speed for each job. Frequency conversion control saves energy and keeps parts working right. Central electrical control connects all the machine’s features. This makes it easy to run automatic lines.

- Touch screens make setup and checking simple.

- PLCs control timing and fin forming steps.

- Inverter speed control changes motor speed for each radiator.

- Rotary encoders check fin position and length.

- Fault protection warns about low oil or material.

- Hydraulic lifting and overload protection make die changes safe.

Control systems help factories make lots of fins quickly. Operators can watch every part and fix problems fast. These systems help with automatic radiator core building and keep radiator quality high.

Energy Efficiency

Energy efficiency is important for every radiator fin machine. DAG makes machines that use less energy but still make many fins. The machine has inverter technology to change how fast the motor goes. This helps save energy when working slow or fast. Operators can pick the speed for each job. The machine only uses the power it needs for the work.

DAG’s radiator fin machine uses a micro oil spray system. This system cuts oil use by about 60%. Using less oil means less waste and lower costs. The machine also turns off by itself when not working. This stops energy from being wasted during breaks.

Note: Saving energy helps factories pay less for power and helps the planet. A radiator fin machine with good energy features saves money over time.

The table below shows how DAG’s radiator fin machine saves energy:

| Feature | Benefit |

|---|---|

| Inverter Speed Control | Uses only needed energy |

| Micro Oil Spray System | Reduces oil and waste |

| Automatic Shut-Off | Stops energy loss |

| Servo Feeding | Precise, efficient movement |

Factories with energy-saving radiator fin machines can make more fins with less power. This helps them keep up with others and follow new rules.

Safety

Safety is very important for every radiator fin machine. DAG adds many safety features to protect people and the machine. The machine has overload protection and emergency stop buttons. These stop the machine if something is wrong.

Operators use a touch screen to run the machine. The screen shows warnings if the machine needs help. The radiator fin machine has guards around moving parts. These guards keep hands and clothes safe from harm.

DAG’s radiator fin machine uses hydraulic lifting for safe die changes. The machine will not work if a guard is open. This keeps people safe during repairs. The machine also has sensors to check oil and material levels. If something is low, the machine gives a warning.

Here are some safety features in DAG’s radiator fin machine:

- Overload protection stops the machine if it works too hard.

- Emergency stop buttons let workers stop the machine fast.

- Guards cover moving parts to keep people safe.

- Hydraulic lifting makes die changes safe and easy.

- Sensors watch oil and material levels for safe work.

- Touch screen alerts warn about problems right away.

- Safety systems help keep workers and machines safe every day.

Tip: Good safety features help workers feel safe. A safe radiator fin machine keeps work going and lowers the chance of accidents.

Compatibility and Integration

Existing Equipment

Manufacturers need to see if a new radiator fin forming machine fits with what they already have. Every factory has its own way of making radiators. Some factories make radiators in groups, while others keep making them without stopping. How a factory works changes how machines fit together. If a factory makes radiators in groups, it needs a machine that can do many jobs. If a factory works all the time, it needs a machine that runs by itself and keeps the same speed.

When getting a new machine, companies should check power, voltage, and how exact it is. A radiator fin forming machine with a 1.5Kw motor and 380V voltage works for most factories. The machine should make fins with 3-5mm accuracy. It must work with both copper and aluminum fins. The machine should be easy to put together and fix. This makes repairs easier and stops long breaks. Good companies like DAG help by giving support and extra parts.

Tip: Always make sure the new machine can connect to your radiator core builder machine. This helps stop problems when making radiators.

Factory Layout

How a factory is set up changes how well a radiator fin forming machine works. Each machine needs enough space to be safe. The machine should fit in the line without slowing things down. Workers need room to move and handle fin materials.

It is best to put the radiator core builder machine close to the fin forming machine. This makes it faster to move fins from one machine to the next. The machine should be easy to reach for repairs. Companies should leave space for more machines if they want to grow. A good setup keeps the radiator line working well and safely.

| Factor | Details |

|---|---|

| Space | Enough room for machine access |

| Flow | Smooth movement of fin parts |

| Safety | Clear paths for workers |

| Expansion | Room for more machines |

Radiator Core Builder Machine Integration

A radiator core builder machine works with the fin forming machine to build radiators. These two machines must match in speed, size, and controls. DAG gives ways to help these machines work together in automatic lines. The radiator fin forming machine can send fins right to the radiator core builder machine. This saves time and keeps radiator quality high.

The machines should not put too much stress on each other or the fins. Both machines need to use the same way to cut fins for good results. They should also work with the same fin styles and materials. You can change things like fin height and design so the machines work for different radiator types.

A table below shows important things for working together:

| Integration Point | Requirement |

|---|---|

| Speed Match | Both machines run at same speed |

| Material Support | Copper and aluminum fin compatibility |

| Control System | PLC and touch screen for both |

| Cut-off Mode | Mechanical cutting for accuracy |

| Customization | Adjustable fin height and design |

Note: When the radiator fin forming machine and the radiator core builder machine work together well, factories work faster and make fewer mistakes. DAG’s automatic lines help companies make more radiators and reach their goals.

Maintenance and Support

Maintenance

Taking care of a radiator fin forming machine is important. Workers should look at the machine every day. They need to check for dust, oil, and loose parts. Cleaning the fin rollers and blades helps make good fins. Putting oil on moving parts stops them from wearing out. It also keeps the machine quiet. DAG gives easy guides for daily and weekly care. Their team helps set up the machine and teaches workers how to keep it working well. Good care lowers the chance of the machine breaking. It helps the radiator line keep running. If workers follow a plan, the machine can make fins for many years. A clean and cared-for machine makes sure each radiator is good.

Spare Parts

Spare parts are important for keeping the machine ready. DAG makes sure spare parts are easy to get. Many people buy spare parts with their machines. This helps them fix problems quickly and avoid long stops. DAG gives a one-year warranty and keeps spare parts ready as part of their service. Getting parts fast means the machine can keep making fins. Customers like DAG for quick help and good support. The company’s focus on spare parts helps factories fill orders and keep fin quality high.

After-Sales Support

After-sales support helps customers use their machine without worry. DAG gives a one-year warranty for every machine. Their team answers questions in one day and gives updates on how the machine is made. They teach technicians for free before sending the machine. Online help is always there for the machine’s life. If a big problem happens, DAG sends experts to help in person. The company also gives free samples and helps check quality. Customers can visit the factory and learn more about the machines. DAG’s support helps factories keep making fins and radiators with good quality. This strong support builds trust and helps customers do well.

Tip: Good after-sales support and easy spare parts help factories keep their radiator fin forming machines working well. This support keeps every fin and radiator high quality.

Training

Training teaches workers how to use the radiator fin forming machine. All factories need workers who know how to run the radiator line. DAG gives training to every worker who will use their machines. The training shows how to set up the machine and make different fin types. Workers also learn how to keep the machine clean. They check the fin rollers and blades before starting work. They learn how to find problems with the fin shape or size.

DAG’s team goes to the factory to give hands-on training. They show how to change fin rollers for different jobs. The team teaches how to use the touch screen and PLC controls. Workers practice making straight, wavy, and louvered fins. They learn how to adjust the machine for thin or wide fins. Training helps workers make sure every fin is the right size and shape.

Good training keeps everyone safe. Workers who know the machine can stop problems early.

A normal DAG training program includes:

- Setting up the machine for new radiator jobs

- Changing fin rollers and blades for each fin type

- Using the touch screen to set fin height and width

- Checking fin thickness for each order

- Cleaning and oiling the machine

- Fixing common problems with the radiator line

The table below shows what workers learn in training:

| Training Topic | Skills Gained |

|---|---|

| Machine Setup | Start and stop the radiator line |

| Fin Roller Change | Make new fin types for radiators |

| Control System Use | Set fin size and speed |

| Maintenance | Clean and oil the fin machine |

| Troubleshooting | Fix fin shape and radiator issues |

DAG also gives videos and guides for training. Workers can watch these to remember each step. The company answers questions after training is done. This help lets workers keep the radiator line running well. Factories that train workers make better fins and radiators. They also have fewer stops and less waste.

Training is not just for new workers. Even skilled workers need updates when the radiator line changes or when new fin types are needed.

A trained team helps the factory make more radiators with good fins. Training saves time and money. It also keeps the radiator line safe for everyone.

Budget and Value

Cost vs. Value

When picking a radiator fin forming machine, buyers should not just look at the price. The real cost is more than what you pay at first. You also pay for energy, fixing the machine, spare parts, and help from the company. Some machines are cheap to buy but break down more or use more power. Other machines cost more but save money later because they work better and last longer.

The table below shows how prices and features can change:

| Brand / Model Category | Price Range (USD) | Key Features / Notes |

|---|---|---|

| Budget / Entry-Level | $700 – $3,150 | Manual or semi-auto machines, basic features, lower cost, fewer options. |

| Mid-Range Versatility | $2,200 – $17,191 | More forming options, moderate price, fits many radiator jobs. |

| Higher-End / Specialized | $14,000 – $100,000+ | Precision CNC, high speed, best for large radiator factories. |

Buyers should remember to add up all costs, like energy, repairs, and training. A machine that costs more at first might save money later if it works faster and needs less fixing.

Brand Comparison

DAG is a top brand for radiator machines. It has fast speed, strong automation, and can do many jobs. Other brands make good machines too, but DAG gives better help and answers faster. The table below shows how DAG and other brands compare:

| Feature / Brand | DAG Radiator Fin Forming Machines | Other Leading Brands (IEA, LLC, SORADIATOR GROUP, FTH Industries) |

|---|---|---|

| Automation Level | Advanced PLC control, easy to use | Automation present, less advanced |

| Speed | Up to 280 m/min, very fast | Lower speeds, less focus on speed |

| Flexibility | Works with many core sizes and materials | Flexible, but not as many options |

| Technical Support | 24/7 help, training, custom options | Good support, but not always 24/7 |

| After-Sales Service | Fast response, full training, custom help | Support varies by supplier |

| Reliability | Built for long hours, trusted by many customers | Reliable, but less focus on repeat buyers |

DAG’s machines help factories make radiators faster and stop less. The company’s team answers questions any time. Many people buy from DAG again because they trust the machines and the help they get.

Long-Term Investment

Buying a radiator fin forming machine is a big choice for a factory. Buyers should think about how the machine will help their business grow. Machines that run fast and do not break often help factories make more radiators each day. Good help and easy spare parts mean the machine does not stop for long.

Picking a good radiator machine can help a factory make more money and have fewer problems. Factories with the right machine can fill new orders and keep customers happy.

When thinking about value, buyers should ask:

- Does the machine save energy?

- Can it make many kinds of radiator fins?

- Is it easy to get help?

- Will it last a long time?

Choosing a machine with strong features and good help lets a factory do better. Over time, the right machine brings more success and more business.

People who work in factories can pick the best radiator fin forming machine by using simple steps. First, they make sure the machine’s features match what the factory needs for making radiators. They check if the radiator core builder machine works well with the machines and space they already have. They look at how much of the work is automatic, how fast the machine makes fins, and how it helps stop mistakes. They think about the future and pick machines that can be upgraded later. They also look at how easy it is to fix the machine, get spare parts, and train workers. They compare how much the machine costs with how much it will save or cost to fix over time. Safety features and certifications keep workers safe and follow the rules. Control systems and energy-saving parts help the radiator work better. By following these steps, factories can connect the radiator core builder machine, make work smoother, and make sure radiators are made well every time. Brands like DAG give strong machines for every radiator core builder machine job.

- Make sure the machine fits the radiator core builder machine’s size, fin type, and materials.

- Check how much work is automatic and how many radiators it can make.

- Think about if the machine can be upgraded for more radiators later.

- Look at how easy it is to fix, get help, and train workers.

- Compare the price with what you get for your money.

- Make sure the machine has safety features and certifications.

- Check if the control systems and energy-saving parts help make radiators better.

- See if the machine works well with the radiator core builder machine and fits in the factory.

Tip: Using these steps helps factories make radiators better and save money for a long time.

FAQ

What materials can DAG radiator fin forming machines process?

DAG machines can use aluminum and copper. These metals are good for car, air conditioner, and factory radiators.

How often should operators perform maintenance on the machine?

Operators need to check and clean the machine every day. Oiling and looking at parts often keeps the machine working well. This stops it from breaking down.

Can one machine produce different fin types and sizes?

Yes. DAG machines have rollers and blades you can change. Operators can make straight, wavy, louvered, or serrated fins. You can also change how tall and wide the fins are.

How does automation improve radiator fin production?

Automation makes work faster and uses less hand labor. Machines with PLC control and servo feeding keep work steady and correct.

What support does DAG provide after purchase?

DAG gives a one-year warranty and spare parts. Their team trains workers and answers questions fast.

Is it easy to integrate DAG machines into existing production lines?

Yes. DAG makes machines that fit into many factories. They work with radiator core builder machines and fit different layouts.

How energy efficient are DAG radiator fin forming machines?

DAG machines use inverter speed control and micro oil spray. These help save energy and cut down on waste.

What safety features do DAG machines include?

DAG machines have overload protection and emergency stop buttons. Safety guards and touch screens show warnings to keep workers safe.