The automotive radiator is an indispensable component in an automobile’s cooling engine cooling system and is developing in a light, efficient, and economical direction. Automotive radiator structures have also continuously adapted to new developments.

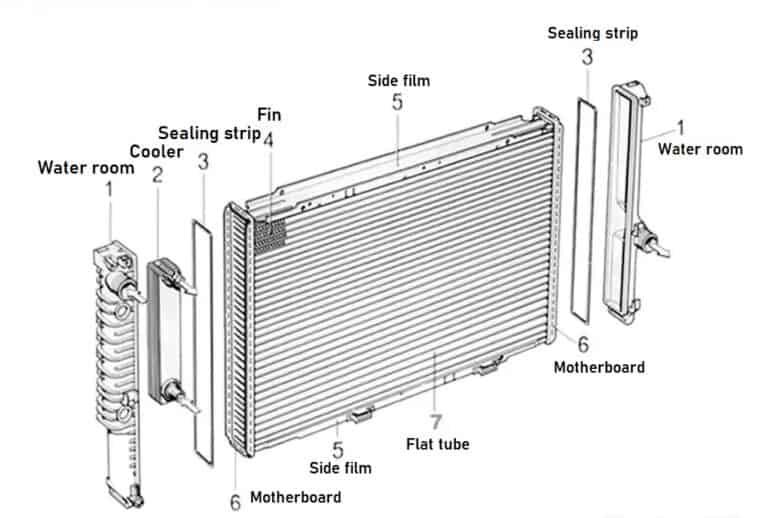

The tube-type radiator core comprises many fine cooling pipes and heat sinks. Most cooling pipes are used in flat cross sections to reduce air resistance and increase heat transfer area.

The radiator core should have sufficient ainable area to allow the coolant to pass. At the same time, it should also have an adequate airflow area to allow enough air to pass the heat of the cooling device by taking away the cooling fluid. At the same time, there must be enough heat dissipation area to complete the heat exchange between coolant, air, and heat dissipation tablets.

The tube band radiator is welded by a wavelet-shaped radiator and cooling tube.

Under the same conditions, the band-type radiator can increase the heat dissipation area by about 12% compared with the tube-type radiator. In addition, the pores, similar to the louver window with disturbing airflow on the radiator, are opened to destroy the flowing air on the rail belt surface. The attachment layer on the top improves the heat dissipation ability.