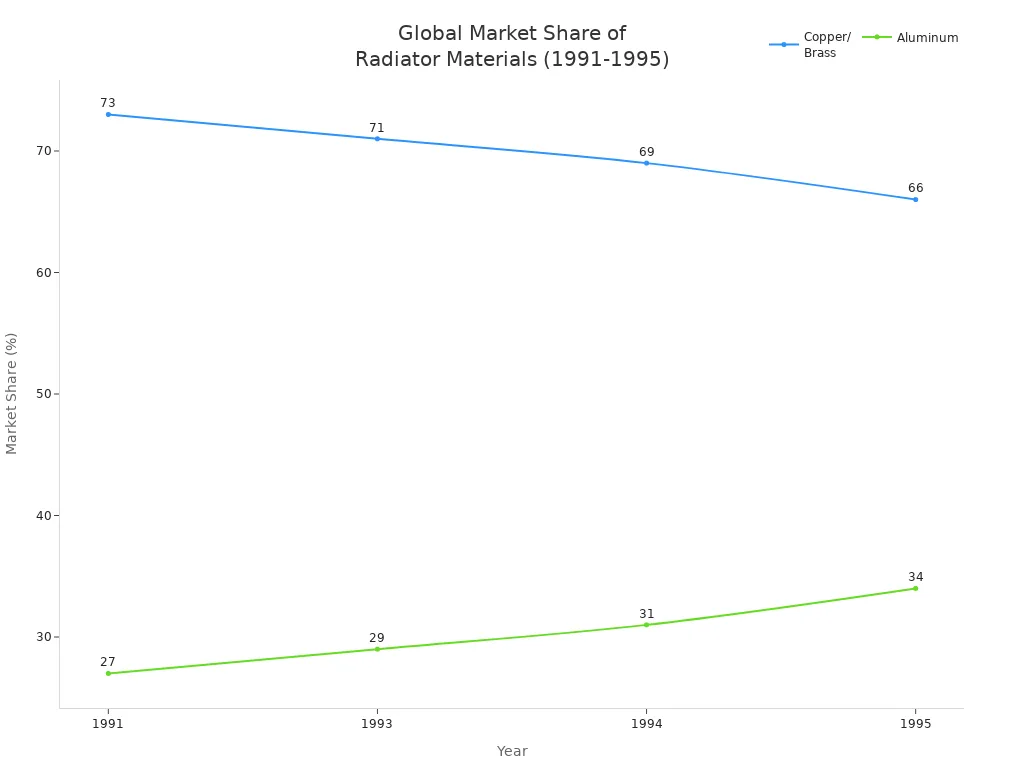

Brazed aluminum radiators are popular because they are light. They cool engines well and do not rust easily. Many car experts pick a braze aluminum radiator for new cars. These radiators have strong joints that do not leak. The market share of radiator materials has changed over time:

| Material | 1991 (%) | 1993 (%) | 1994 (%) | 1995 (%) |

|---|---|---|---|---|

| Copper/Brass | 73 | 71 | 69 | 66 |

| Aluminum | 27 | 29 | 31 | 34 |

People pick an aluminum radiator for many reasons:

- It is light, so cars handle better.

- It cools the engine well.

- It does not rust, so it lasts longer.

- It is cheaper to make.

- It fits well in new cars.

- The joints are strong and do not leak.

Choosing the best radiator for your car involves several factors, including the vehicle’s specific needs, your budget, and desired longevity. While a brazed aluminum radiator offers numerous advantages, other different types of aluminum radiators might be more suitable depending on your car’s application.

Key Takeaways

- Brazed aluminum radiators are known for being lightweight and strong. They significantly contribute to engine cooling, which in turn enhances your car’s overall performance benefits and extends its lifespan.

- These radiators exhibit excellent corrosion resistance. Special aluminum alloys and zinc coatings are used to prevent rust, reducing the need for frequent maintenance.

- Their superior heat exchange capabilities are a hallmark. Wide fin spacing and thin tubes facilitate rapid heat dissipation, often outperforming traditional copper or brass radiators in effective cooling.

- Aluminum radiators are 30-50% lighter than their copper or brass counterparts. This weight reduction can lead to improved fuel efficiency and better vehicle performance.

- However, repairing brazed aluminum radiators can be challenging. Regular inspections and the use of the correct coolant are crucial for maximizing their lifespan.

- When selecting a radiator, consider your vehicle’s usage, your budget, environmental conditions, and your specific cooling needs. For instance, for high-performance vehicles, a multi-pass radiator or even a triple-pass radiator design in brazed aluminum can offer superior engine cooling.

- Modern brazed aluminum radiators feature advanced designs. The furnace brazing process creates stronger, more durable joints, contributing to their longevity.

- Proper maintenance, including regular cleaning and using the recommended coolant, is essential to protect the radiator from the elements and safeguard your engine.

Braze Aluminum Radiator Basics

Construction

A brazed aluminum radiator is meticulously crafted from robust aluminum alloys. Its core, exclusively made of brazed aluminum, ensures both joint strength and optimal heat exchange. TIG welding is employed for precise and durable connections between components. The radiator incorporates louvered fins, which significantly enhance effective cooling by maximizing airflow. This construction contributes to the overall performance benefits in engine cooling.

| Component | Material/Description |

|---|---|

| Fins | Aluminum, different patterns for better heat |

| Braze Sheets | Aluminum sheets that hold fins and bars |

| Bars | Aluminum bars or tubes made by extrusion |

| Tubes | Extruded aluminum tubes for strength |

| Headers | Aluminum headers, welded to the core |

| Manifolds | Welded aluminum, custom pipes |

| Tanks | Welded aluminum, made in different ways |

| Material Enhancements | Zinc-mixed aluminum to stop corrosion |

| Joining Methods | Brazing and TIG welding |

This way of building makes the radiator light but strong. Zinc-mixed aluminum helps stop rust. This makes the radiator last longer.

How It Works

The braze aluminum radiator helps keep the engine cool. Coolant moves through the aluminum tubes inside the radiator. When the engine runs, it heats up the coolant. The louvered fins take heat from the coolant. They move the heat to the air that goes through the radiator. This keeps the engine from getting too hot.

Brazing connects the thin fins to the tubes. This makes the joints strong and stops leaks. Brazing uses less heat than welding. This means the aluminum does not get damaged. The radiator can handle high pressure and heat changes. The strong joints help move heat well, which is needed for cooling.

Note: Brazing lets the radiator have many shapes and designs. This helps it fit in many types of cars.

Common Uses

Car makers use braze aluminum radiators in many vehicles. You can find them in regular cars, light trucks, and fast cars. Racing teams like them because they are light and cool well. Luxury cars use them because they do not rust and last a long time.

- Braze aluminum radiators are used in:

- Regular cars and light trucks

- Fast and racing cars

- Luxury cars

- Foreign cars, mostly in Europe and America

More car makers use aluminum radiators now. They want better cooling and lighter cars. Braze aluminum radiators are now common in new cars that need good cooling and long life.

Aluminum Radiators: Key Benefits

Heat Dissipation

Brazed aluminum radiators get rid of heat very well. They have wide spaces between fins and thin tubes. This lets air move easily through the radiator. More air helps take heat away from the coolant faster. Aluminum moves heat quickly from the coolant to the fins.

Copper can move heat better than aluminum by itself. But copper/brass radiators use a tin-lead layer. This layer makes them lose heat less well. Aluminum radiators do not have this problem. They often cool as well or even better than copper/brass radiators, especially when it is hard for the engine.

| Material | Thermal Conductivity (W/m·K) | Heat Dissipation Rate Compared to Brass |

|---|---|---|

| Copper | 406–430 | N/A |

| Aluminum | 353–390 | About double that of brass |

| Brass | 109–125 | Baseline |

Lab tests show brazed aluminum radiators work well at different air speeds. They also do well with different coolant flow rates. These tests check air and coolant temperatures, pressure drops, and how much heat is removed. The results show aluminum radiators cool well and move heat fast, even in big trucks. Tests on real cars show these radiators last a long time and work in tough driving.

Lightweight

Aluminum radiators are much lighter than copper/brass ones. They can weigh 30–50% less for the same car. Lighter radiators help cars speed up faster and turn better. They also help save gas because the engine has less weight to move.

- Lighter radiators make the whole car weigh less.

- Less weight means the car uses less fuel.

- Cars handle better with a lighter front end.

- More space under the hood helps air move and cool better.

Most new cars and trucks use aluminum radiators for these reasons. The light design helps cars perform well. It also makes the radiator easier to put in or take out.

Corrosion Resistance

Aluminum radiators do not rust as much as other types. The alloys used, like AA3003 and AA3005, work well in hard places. Lab tests show these alloys last longer than cold-rolled steel and electrogalvanized steel. Some aluminum alloys, like 3003 with zinc, resist rust even more and get fewer pits.

- Aluminum alloys can last up to 15 years with the right coolant.

- Special alloys with less iron and silicon resist rust better.

- Using more ethylene glycol in the coolant slows down rust.

- Aluminum radiators handle surface and electric rust better than steel.

This means the radiator keeps working for many years. It also means you do not need to fix or change it often, so you save money over time.

Durability

Many people pick a brazed aluminum radiator because it lasts a long time. Most of these radiators work well for 8 to 10 years. Some top models can last up to 15 years if you take care of them. This is as long as, or longer than, brass and copper radiators. Those usually last about 6 to 10 years.

A few things help the radiator last longer. The strong brazed joints stop leaks and cracks. The aluminum alloys help stop rust and corrosion. This means the radiator works even in bad weather or on rough roads. Cleaning the radiator and using the right coolant also help it last longer.

Tip: If you check for leaks and keep the coolant clean, your radiator may last longer.

A radiator that lasts saves you money over time. You will not need as many repairs or new parts. Many car owners feel better knowing their aluminum radiator is reliable. This is true for people who drive in very hot or cold places. The strong build and rust resistance make these radiators a good choice for many years.

Aluminum Radiator Drawbacks

Cost

Brazed aluminum radiators usually cost more than copper-brass ones. This is because they need special tools and good materials. Many car owners see the higher price when they buy a new radiator. Making these radiators takes skilled workers and special machines. This makes them more expensive. Some cars do better with these radiators because they last longer and are lighter. Over time, this can make up for the high price. But people who do not have much money may find the cost too high.

Repairability

Fixing a brazed aluminum radiator is not easy. The strong joints made by brazing stop leaks but are hard to fix. Mechanics often have trouble fixing cracks or leaks in the tubes. Many repair shops say it is better to get a new radiator. There are many reasons why repairs are tough:

- If the flux is not rinsed off, it can cause damage.

- It is hard to keep the right heat because aluminum cools fast.

- Aluminum gets a hard oxide layer that stops bonding, so cleaning is needed.

- Too much heat can melt thin parts.

- Flux must remove the oxide layer for a good bond.

- The flux can be toxic, so safety steps are needed.

- Filler metal may not fill thick joints well.

- Aluminum moves heat fast, so it is hard to keep the area hot.

- The oxide layer comes back quickly, so cleaning and flux are very important.

These problems mean even good mechanics may not be able to fix a broken radiator. Most people get a new one to stay safe and avoid more trouble.

Maintenance

Brazed aluminum radiators do not need as much care as copper-brass ones. Aluminum makes a layer that protects it from rust. New cars use designs that help stop rust even more. Drivers still need to change the antifreeze and use clean water. Copper-brass radiators have more rust problems because they use different metals. This means they need to be checked and cleaned more often.

Tests show that pure aluminum can break if not made well. Stronger materials and smart fin shapes help stop rust and make the radiator last longer. Good brazed aluminum radiators need less care than old types. Checking the coolant and cleaning the radiator helps the engine stay cool and the car run well.

Tip: Always use the right coolant and keep the radiator clean for best results and longer life.

Radiator Comparison: Aluminum vs. Other Types

Copper/Brass Radiators

Copper/brass radiators have been used for many years. Old cars and big trucks often use them. These radiators have copper tubes and fins. The tanks and headers are made from brass. Solder holds all the parts together. Copper moves heat better than aluminum. But the solder makes cooling less effective. Copper/brass radiators can weigh up to 60% more than aluminum ones. This extra weight makes cars harder to handle and uses more gas.

| Attribute | Brazed Aluminum Radiators | Copper/Brass Radiators |

|---|---|---|

| Cooling Capacity | Uniform heat transfer; wide tubes and strong fin contact | High base conductivity, but solder reduces efficiency |

| Weight | 30-60% lighter | Heavier |

| Durability | More corrosion-resistant; strong in vibration | Prone to corrosion; easier to repair |

| Construction Method | Brazed all-aluminum core | Soldered mixed metal core |

| Repairability | Harder to repair | Easier to repair |

| Application Preference | Modern, performance, daily-use vehicles | Vintage, heavy-duty vehicles |

You can fix copper/brass radiators with simple tools. But they rust faster if you do not paint or care for them. Their solder joints can get weak when the car shakes a lot. Most new cars use aluminum radiators now. Aluminum is lighter and lasts longer.

OEM Radiators

OEM radiators come in most new cars from the factory. Car makers design them to be cheap and easy to make. Most OEM radiators have aluminum cores and plastic end tanks. The plastic tanks are held on with crimped tabs. This keeps the price low but can cause leaks as the plastic gets old.

Aftermarket aluminum radiators are better than OEM ones. They use B-tube technology to make the tubes stronger and cooler. These radiators use tough aluminum for tubes, fins, and brackets. TIG-welded aluminum end tanks replace the plastic ones. This makes them stronger and last longer. Aftermarket radiators pass hard tests for airflow, pressure, shaking, and rust. OEM radiators are not as strong or cool as well as aftermarket ones. Aftermarket models often have custom end tanks and CNC fittings. OEM radiators rarely have these features.

Tip: If you want your engine to stay cool and work well, pick an aftermarket aluminum radiator instead of an OEM one.

DAG Aluminum Radiators

DAG aluminum radiators are known for being strong and reliable. Makers use a Giant Vacuum Aluminum Brazing Furnace to build them. The furnace works in a vacuum, so no air gets in. This stops rust and dirt from forming. The joints are pure and strong because no flux is needed. The welds are almost as strong as the main metal. This helps the radiator last longer and not leak.

The furnace keeps the heat even and steady. This stops problems like rust or holes from happening. The vacuum also helps stop rust. DAG can change the furnace to make different sizes of radiators. The design saves energy and cuts down on waste. This helps lower the cost. These things make DAG aluminum radiators a great pick for cars and factories that need good cooling.

| Feature | Explanation |

|---|---|

| Working Principle | High vacuum prevents oxidation; no flux needed |

| Product Quality | Strong, pure welds; excellent airtightness and corrosion resistance |

| Temperature Control | Automatic, precise heating and cooling |

| Customization | Fits different radiator sizes and production needs |

| Energy and Waste | Efficient design reduces waste and energy use |

DAG aluminum radiators are trusted for their strength and performance. Many companies use them when they need engines to stay cool.

Other Alternatives

Many cars use radiators made from more than just aluminum or copper/brass. Some radiators are plastic, composite, or stainless steel. Each kind has special features that change how it works, how much it costs, and how long it lasts.

Plastic radiators are common in new cars. The end tanks are plastic, but the core is still metal. This makes the radiator lighter and cheaper. But plastic can break after many hot and cold cycles. If a plastic tank breaks, you must replace it. Fixing it is almost never possible.

Composite radiators use more than one material. Some mix aluminum and plastic. Others use strong plastics called reinforced polymers. These radiators are not too heavy and are pretty strong. They do not rust as fast as metal ones. But they may not work well with high pressure or very hot engines.

Stainless steel radiators are used for special jobs. People pick stainless steel because it does not rust and can handle chemicals. These radiators are good for boats or factories. Stainless steel is heavier than aluminum. It also costs more to make. Most car companies do not use stainless steel for these reasons.

Some big trucks use radiators with thick cores or special coatings. These help the radiator work in tough places. They protect against rocks, shaking, and chemicals. But thick cores can block air and make cooling worse.

The table below shows how these radiator types compare:

| Characteristic | Plastic/Composite Radiators | Stainless Steel Radiators | Brazed Aluminum Radiators |

|---|---|---|---|

| Weight | Lightest | Heaviest | Light |

| Durability | Moderate (prone to cracking) | High (resists rust, heavy) | High (resists corrosion, light) |

| Repairability | Low | Moderate | Low |

| Cost | Lowest | Highest | Moderate |

| Application Suitability | Daily-use, economy cars | Marine, industrial, specialty | Most modern vehicles, trucks |

| Cooling Performance | Adequate for standard engines | Good, but heavy | Excellent with modern design |

Note: New brazed aluminum radiators have better fins and tubes. These changes help them cool as well or better than old copper or brass ones. Brazing makes the joints strong and stops leaks. This helps the radiator last longer and work better.

When picking a radiator, think about what your car needs. Plastic and composite radiators are good for daily driving and cheap fixes. Stainless steel is best for tough or dirty places. Brazed aluminum radiators are light, strong, and cool engines well. That is why most new cars use aluminum radiators today.

Choosing the Right Radiator

Vehicle Use

Picking the right radiator starts with knowing how you use your car. Cars for daily driving, work, or racing need different radiators. A family car usually needs a normal radiator to stay cool. Trucks that carry heavy things need a bigger radiator. Race cars need the best aluminum radiators to handle lots of heat.

Key things to think about for your car:

- Make sure the radiator fits your car’s make and year.

- The radiator must fit in the space under the hood.

- Check if the hoses and mounts match your car’s parts.

- For race or off-road cars, pick a radiator with a bigger core and more rows. This helps it cool better.

Tip: Always look at your car’s manual or ask a mechanic before picking a radiator for special cars.

Budget

How much money you have is important when picking a radiator. Some radiators cost less at first but may break sooner. Others cost more but last longer and need fewer repairs. The table below shows how much different radiators cost now and later:

| Aspect | Brazed Aluminum Radiator | Copper Radiator |

|---|---|---|

| Initial Investment | Lower | Higher |

| Maintenance | Regular upkeep needed | Easier to maintain |

| Repairability | Hard to repair | Easier to repair |

| Durability | Good, but can corrode | Very durable |

| Long-Term Costs | Can be higher | Often lower |

You should think about the price now and the cost to fix or replace it later. Reading what other people say and checking the warranty can help you choose well.

Performance Needs

What your car does changes what radiator you need. Fast cars and big trucks need radiators that can handle more heat and pressure. Here are some important things for performance:

- The radiator must keep the engine cool enough.

- It should be as big as the space allows.

- Good fins and open spaces help air move through it.

- Aluminum radiators are light and do not rust, so many people like them.

- The radiator must not leak when under high pressure.

- More rows and passes help cooling but may need a stronger pump.

- Special coatings and good alloys help the radiator last longer.

Note: Making the cooling system stronger can help in hot weather or hard driving.

Pick a radiator that matches how you use your car, your budget, and what your car needs. This helps your engine stay cool and safe in all kinds of driving.

Climate

Climate is very important for how long a radiator works well. Different places have different weather and air. These things can change how a radiator works as time goes by. A study in southern Sweden checked brazed aluminum radiators in real cars. The study showed that weather and the environment matter more than how old the radiator is. Some radiators had a lot of corrosion after just a few years. Others had only a little corrosion even after being used longer. This shows that things like rain, salty air, and pollution can hurt a radiator more than just age.

Drivers near the ocean deal with salty air. Salt makes metal rust faster. Cities with lots of pollution have chemicals that can damage the radiator. Places with lots of rain or snow have more water around the radiator. Water can get stuck and make the radiator rust faster. Dry places slow down rust, so radiators last longer there.

Big changes in temperature also matter. Hot days and cold nights make metal move. This can stress the joints and seals. Over time, this can cause leaks or cracks. In cold places, road salt in winter can stick to the radiator. If you do not wash it off, the salt can damage the metal.

Drivers can do a few things to help their radiator last longer in tough weather:

- Wash the radiator with clean water after driving on salty roads.

- Park in a garage or under cover to keep off rain and snow.

- Look for rust or leaks when you check your car.

- Use the right coolant to stop freezing and rust.

Tip: Cleaning and checking your radiator often helps stop weather damage. These easy steps can help your radiator last longer.

Weather and the environment change how well a radiator works. If drivers know about their local weather, they can protect their radiator. This keeps the engine safe and working in any kind of weather.

Real-World Feedback

Enthusiast Views

Car fans have strong thoughts about brazed aluminum radiators. Many like that these radiators are lighter and cool better. Some say they can be half the weight of copper-core ones. They also cool engines up to 20% better. People like that furnace-brazed cores do not crack as much as plastic tanks.

- Lighter radiators help cars turn better on race tracks.

- Furnace-brazed joints stop leaks and last longer than epoxy parts.

- Aluminum tanks do not break like plastic, so they are more reliable.

But there are some problems too. Sometimes, radiators fail if used as a support in old cars. Epoxy-bonded aluminum radiators can get brittle and start to leak. If they break, you often have to buy a new one. Car fans agree that how a radiator is made matters more than just the material.

Everyday Drivers

Most drivers want a radiator that works well and needs little care. Many pick aluminum radiators because they do not crack like plastic tanks. Drivers notice these radiators last longer and need fewer repairs. In daily driving, the radiator keeps the engine cool, even in traffic or hot days.

Many drivers say, “I got an aluminum radiator, and now my car stays cooler and I do not worry about leaks.”

Plastic tanks and thermostat housings often break first in old cars. Aluminum radiators fix this by being stronger. Most drivers do not feel a big change when driving, but they like having fewer problems and less time at the repair shop.

Expert Opinions

Car experts see many good things in brazed aluminum radiators. Furnace-brazed cores make strong joints and do not need epoxy, which can leak. Experts say more fins and lighter weight help cooling and car performance. They also say aluminum radiators do not rust easily and work in many places.

- Experts say to use rubber or foam mounts to stop shaking.

- Hard mounts can make aluminum crack, especially in racing or rough roads.

- Picking the right mount and material helps the radiator last longer.

Experts warn about some weak points too. Bad brazing can bend the radiator or make it weaker. They say it is important to build and install the radiator carefully. If done right, brazed aluminum radiators cool well and last a long time.

Brazed aluminum radiators have many good points. They cool engines well and are built strong. They also do not rust easily. Many experts talk about these good things:

- They move heat fast, so engines stay cool.

- They are strong, so they can be smaller and lighter.

- They do not bend or crack easily.

- Their design helps coolant move better.

- They break less often than radiators made with different materials.

But these radiators usually cost more money. They also need to be taken care of the right way. The best radiator depends on how you use your car and how much you want to spend. It is smart to ask an expert for help. Making radiators in special machines, like the DAG Giant Vacuum Aluminum Brazing Furnace, helps them work better and last longer.

FAQ

What makes brazed aluminum radiators different from traditional radiators?

Brazed aluminum radiators use aluminum alloys and special furnace-brazed joints. These joints are strong and do not leak easily. Traditional radiators use copper or brass with soldered joints. Soldered joints can make the radiator heavier and not cool as well.

Can a brazed aluminum radiator fit any vehicle?

Brazed aluminum radiators come in many sizes and shapes. Makers design them to fit lots of vehicles. You should always check your car’s details or ask a pro before you buy one.

How long does a brazed aluminum radiator usually last?

If you take care of it, a brazed aluminum radiator can last 8 to 15 years. Using the right coolant and cleaning it often helps it last longer. Bad weather or not taking care of it can make it wear out faster.

Are aluminum radiators hard to repair?

Fixing aluminum radiators is tough. The brazed joints and thin metal need special tools and skills. Most shops say it is better to get a new radiator if it breaks.

Do aluminum radiators need special coolant?

Aluminum radiators work best with coolants made for aluminum. These coolants stop rust and help the radiator last longer. Always use the coolant your car maker says is best.

Why do performance vehicles use brazed aluminum radiators?

Performance vehicles need to stay cool and be light. Brazed aluminum radiators help with both. Their design keeps engines cool when working hard, so racers and fast cars use them a lot.

How does climate affect aluminum radiator performance?

Very hot or cold weather, salty air, and pollution can hurt the radiator. Cleaning it and using the right coolant helps protect it. People in tough climates should check their radiators more often.

What role does the DAG Giant Vacuum Aluminum Brazing Furnace play in radiator quality?

The DAG Giant Vacuum Aluminum Brazing Furnace makes strong, clean joints in aluminum radiators. Its vacuum technology helps make radiators that last longer and work better for cars and factories.