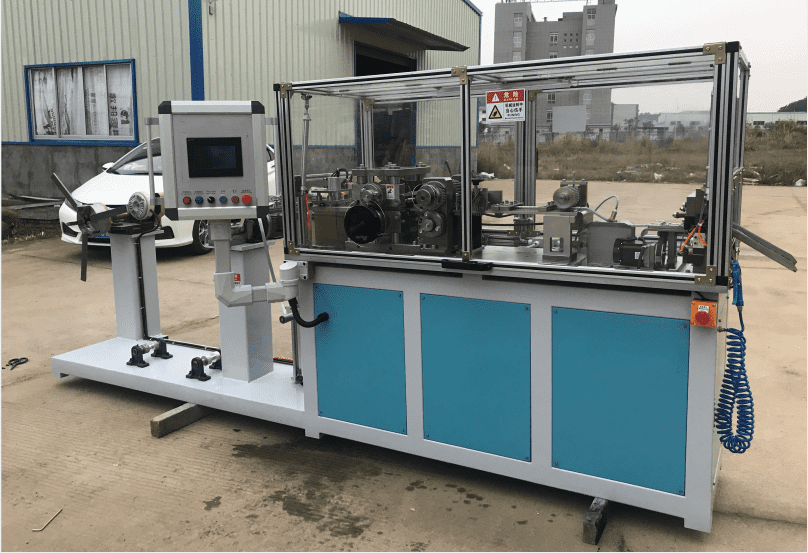

Radiator Crimping Machine Solutions for Better Results

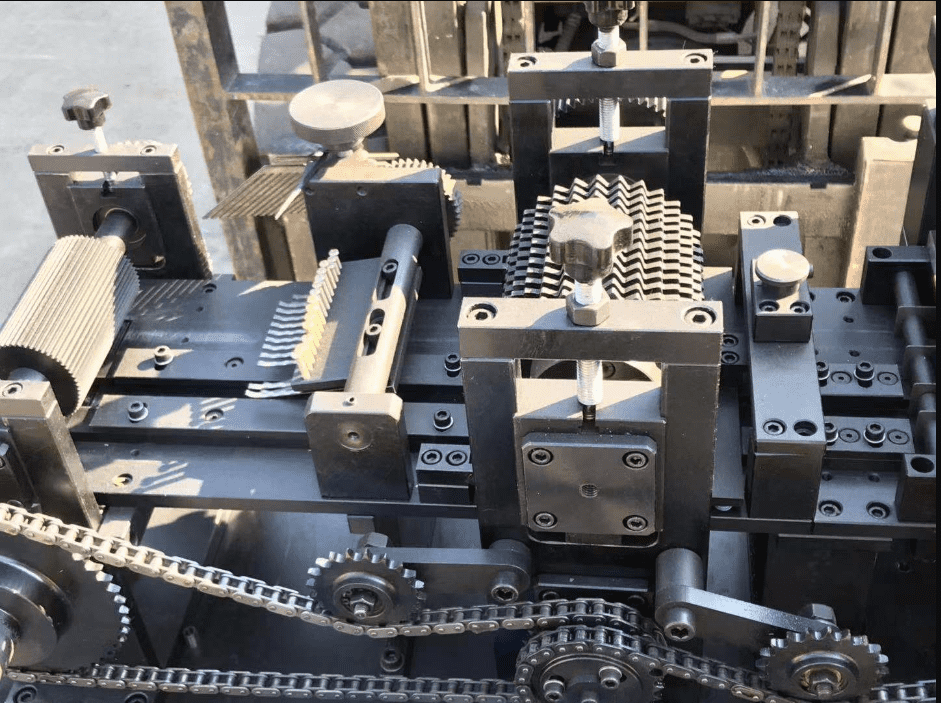

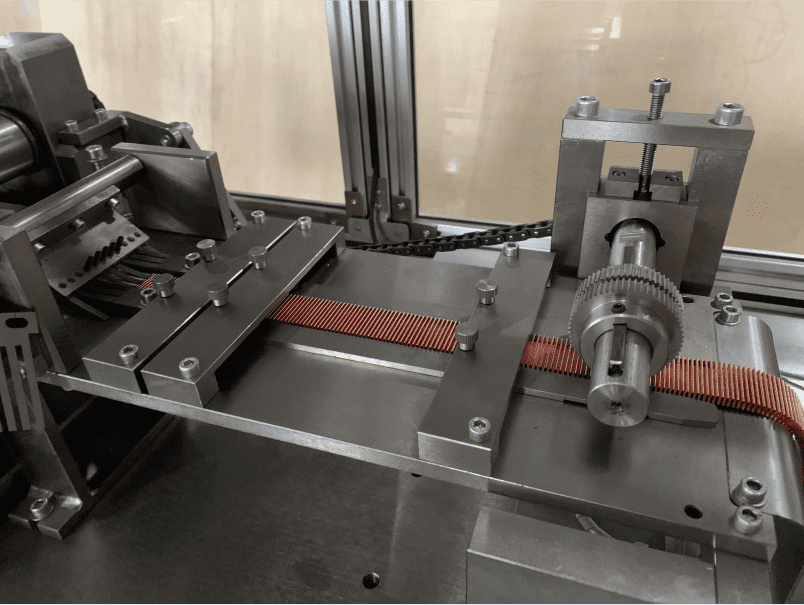

Choosing the right Radiator Crimping Machine can change how factories work. The best machines help work go faster and make better products. They also work well every time. Companies can pick manual, semi-automatic, hydraulic, or fully automatic machines. Each kind fits different jobs and factory sizes. The right machine helps factories make more and get the same good results each time.