Trusted Radiator Machine Suppliers for Cars and Trucks

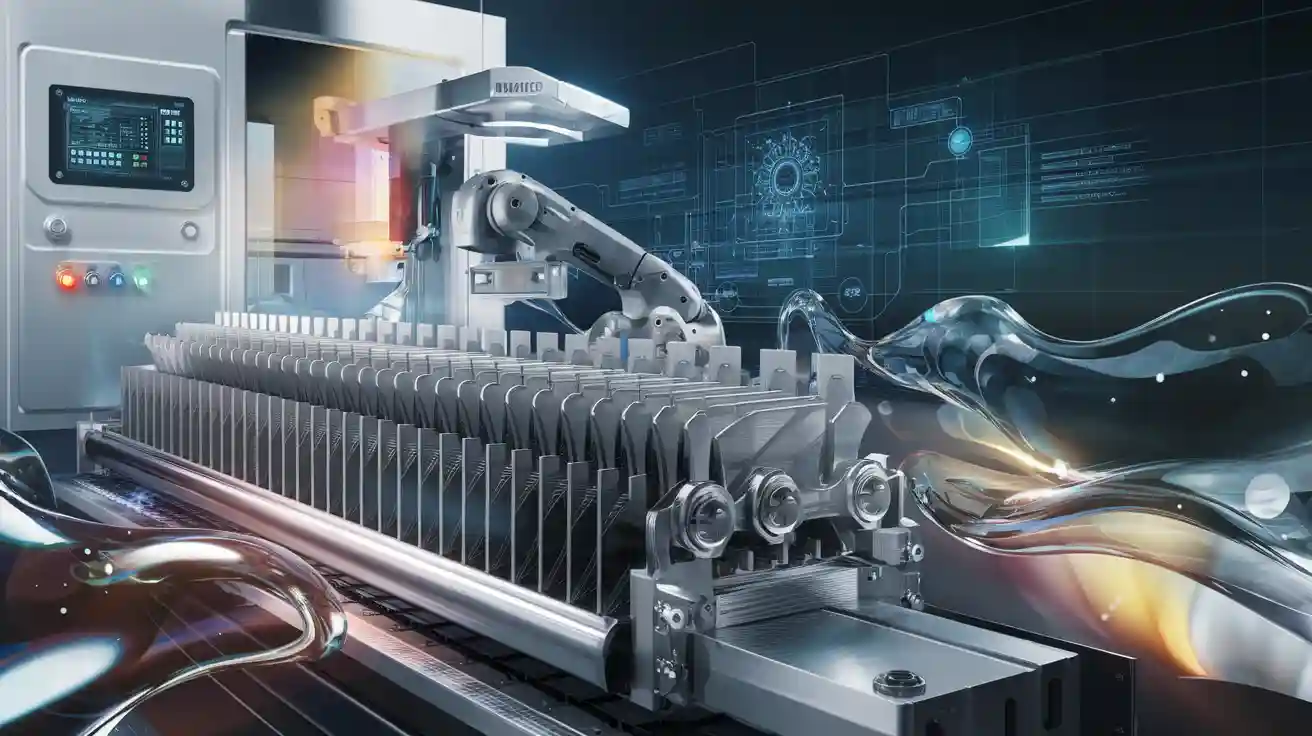

DAG, Atlas Radiator Inc, Guangdong Faret Auto Radiator, Radiator Supply House, and American Radiator are trusted suppliers in the car industry. These companies help radiator makers who want machines that work well and give the same good results every time. Many buyers from Egypt, Iran, and Europe pick their radiator making machine for cars and trucks, which shows people around the world trust them. DAG’s radiator making machine and tank radiator making machines help make radiators for both cars and trucks, so car makers can give strong and safe radiators. High customer happiness, good technical help, and OEM services make these suppliers a top pick for the car industry.