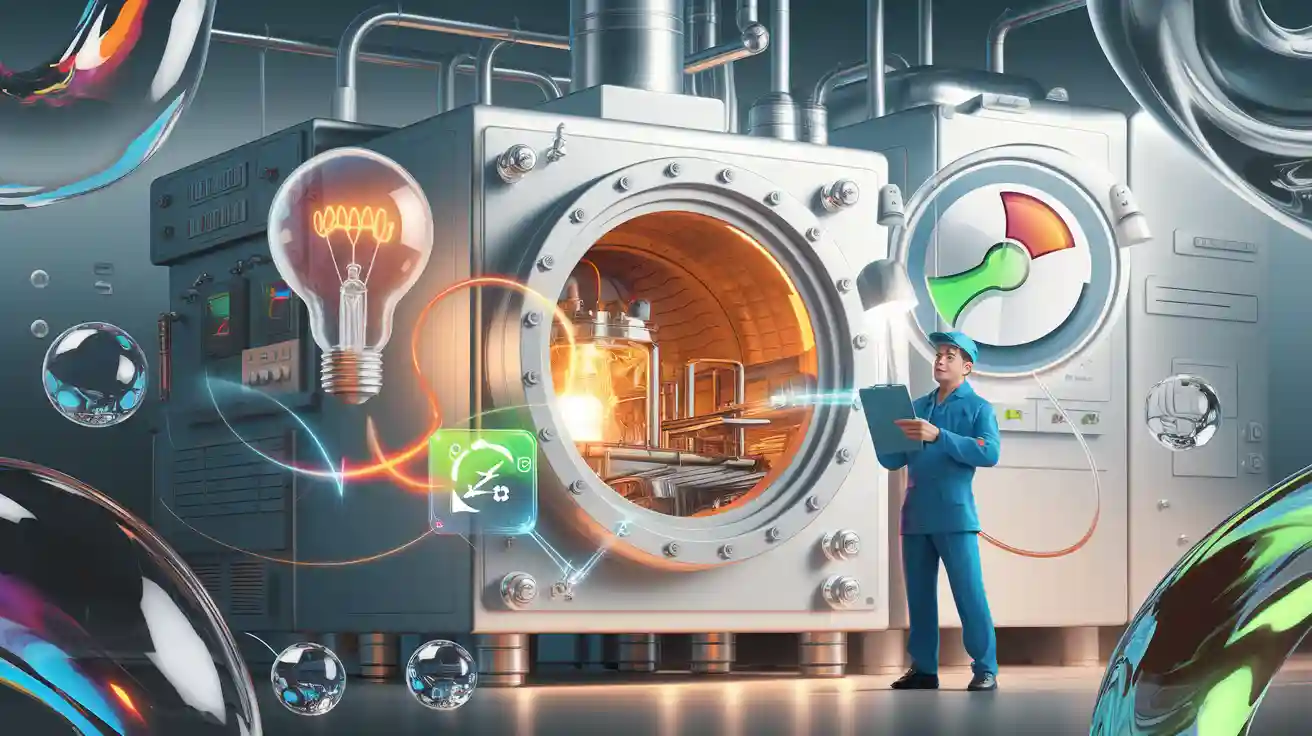

What Makes an Aluminum Brazing Furnace Truly Energy Efficient

An energy-efficient aluminum brazing furnace has special insulation. It uses exact temperature control and smart air management. Automation and regular care help it work better. DAG makes its furnaces to use less energy and save money. The furnaces also make high-quality parts. These things make the brazing process steady and efficient.