Manufacturers looking for the best automotive radiator core making machine in 2025 will see top choices like DAG and the ZPX-280 model. These machines work well because they use a lot of automation. They make products quickly and can be changed for special needs. They can handle many core sizes and fin types. This helps them fit new car needs. The industry is moving toward electric and hybrid vehicles. This change means there is more need for real-time thermal management. There is also more use of materials like aluminum that are better for the environment.

Customization and sustainability are still very important. Manufacturers want machines that save energy and meet tough market rules.

Table of Contents

Key Takeaways

- The best radiator core making machines in 2025 use automation. This helps them work faster and more accurately. It also helps factories keep up with more orders.

- Different machines are good for different jobs. Big factories like fast, fully automated models such as DAG. Smaller shops may want simpler and cheaper machines like the Hydraulic Core Machine.

- Customization is very important. Machines that let you change core size, fin type, and branding easily help companies stay flexible. This also helps them compete with others.

- Material compatibility is important too. Most machines work with aluminum. Some machines can also use copper or brass. This gives companies more choices for their products.

- New technology in these machines helps a lot. Features like real-time monitoring and smart controls make products better. They also help lower mistakes.

- Automation means less manual work. It also means fewer mistakes and faster production. This makes work more efficient and saves money.

- Good after-sales support is important. Training and technical help keep machines working well. This also helps stop long breaks in work.

- Picking the right machine is a big decision. You need to think about how much you want to make, how much automation you need, what materials you use, how much you want to customize, and your budget. This helps you reach your business goals.

Comparison Overview

Key Specifications

In 2025, manufacturers have many good choices for an automotive radiator core making machine. The table below shows the most popular models. These are DAG Radiator Making Machine, ZPX-280, Hydraulic Core Machine, Automated Matrix Machine, and Core Fin Radiator Machine.

| Model | Automation Level | Production Speed | Supported Core Sizes | Material Compatibility | Customization Options |

|---|---|---|---|---|---|

| DAG Radiator Making Machine | Full | Up to 600mm/min | 150mm – 800mm | Aluminum, Copper | Yes |

| ZPX-280 | Semi/Full | Up to 500mm/min | 120mm – 700mm | Aluminum | Yes |

| Hydraulic Core Machine | Semi | Up to 400mm/min | 100mm – 600mm | Aluminum, Brass | Limited |

| Automated Matrix Machine | Full | Up to 550mm/min | 130mm – 750mm | Aluminum | Yes |

| Core Fin Radiator Machine | Full | Up to 580mm/min | 140mm – 780mm | Aluminum, Copper | Yes |

Tip: When you compare machines, look at the core sizes they support. Also, check what metals each model can use. This helps you pick equipment that fits your needs.

Feature Highlights

Every automotive radiator core making machine has special features. These help manufacturers keep up with new needs.

- DAG Radiator Making Machine uses a smart PLC control system. Operators can change settings for different radiator types. It makes products fast and with great accuracy. DAG lets you add your own brand and labels, so your business stands out.

- ZPX-280 can switch between semi and full automation. It is good for both small and big jobs. This model works with many aluminum core sizes. It also has safety features to protect workers.

- Hydraulic Core Machine runs with hydraulic power for steady work. It is best for those who want reliable results and some automation. This model can use both aluminum and brass, so it works for many products.

- Automated Matrix Machine is fully automatic and easy to use. It makes radiator cores the same way every time, with little help from people. The design lets you quickly change to different core sizes.

- Core Fin Radiator Machine is great for making tricky fin shapes. It works fast and lets you customize a lot. This model is perfect for making special radiator designs for unique vehicles.

Manufacturers should think about these features before picking a machine. The best choice depends on how much you need to make, what materials you use, and how much automation you want.

Automotive Radiator Core Making Machine Reviews

DAG Radiator Making Machine

Features

DAG Radiator Making Machine has many helpful features for today’s factories. It uses full automation, so workers save time and make fewer mistakes. The smart PLC control system lets people change settings for different radiator types. This machine can use both aluminum and copper. DAG lets you add your own brand and labels. The design makes it easy to add to old production lines.

Performance

DAG Radiator Making Machine works fast, up to 600mm each minute. It stays steady, even during long work hours. The machine makes radiator cores with high accuracy and few mistakes. Many companies pick this model because it is reliable and always works well. It can make many core sizes, from 150mm to 800mm. This means it is good for both normal and special radiator designs.

Technology

DAG uses new technology in its radiator core making machine. It has servo motors and a PLC controller for exact moves and control. Workers can watch and change the process as it happens. The system lets you make special changes for unique jobs. DAG uses strong parts, like laser cutting and CNC bending machines, to make sure it lasts and works well.

User Feedback

Manufacturers say they are very happy with the DAG Radiator Making Machine. Many people like that it is easy to use and does not need much fixing. The brand has a 95% repurchase rate, which shows people trust it. Users also like the 24/7 technical help and training. These things help companies keep their work going without problems.

Use Cases

DAG Radiator Making Machine is good for many jobs. It works for automotive radiators, oil coolers, air conditioning evaporators, and condensers. The machine is great for big factories and small workshops. Companies that need special products or change products often like DAG’s flexible design and support.

ZPX-280 Model

Features

The ZPX-280 Model is known for its smart automation and easy use. It can switch between semi and full automation. The machine can make many aluminum core sizes, so it fits different radiator types. Safety features keep workers safe while using it. The design makes setup fast and fixing easy.

Performance

The ZPX-280 Model can work at speeds up to 500mm per minute. It is fast and still makes accurate products. The machine is good for both small and big jobs. Workers can change settings quickly for different products. This helps companies keep up with new market needs.

Technology

The ZPX-280 Model uses many new technologies:

- A 17x par-focal zoom lens lets you adjust quickly and stay focused.

- The electronic ND filter helps control light and keeps the picture clear.

- Stacked sensor technology makes the machine more sensitive and stops rolling shutter problems.

- HDR recording, like HLG and S-Log3, gives better color and a wide range of light.

- Networking lets you live stream, upload in the background, and control the machine from the web.

- Workflow tools, like proxy recording and saving to outside drives, make work faster.

- The audio system has four channels and many inputs for tough jobs.

These features help the ZPX-280 Model do better than older machines. It is easy to move, gives great image quality, and works fast, so it is good for busy factories.

User Feedback

People like the ZPX-280 Model because it is reliable and has smart features. Many workers say it is simple to use and quick to set up. Both big and small companies like the flexible automation. Users also talk about the strong safety and helpful workflow tools.

Use Cases

The ZPX-280 Model is used for many things. Companies use it to make automotive radiator cores, especially when they need to change products often. The machine works well in big factories and small shops. Its smart technology is great for companies that want speed, flexibility, and good quality.

Automated Matrix Machine

Features

The Automated Matrix Machine is easy to use and has smart automation. Workers can set it up fast for many radiator core sizes. It works with lots of fin types, so it fits many car jobs. Safety sensors and error checks help keep workers safe and stop problems. You can change settings to fit special needs.

Performance

This machine works fast, up to 550mm each minute. It gives steady results and keeps product quality the same. The machine stays accurate, even when used for a long time. Companies make more products and get better results than by hand. It finds and fixes mistakes early, so more products are finished right.

Technology

The Automated Matrix Machine uses PLC controllers and servo motors for exact moves. It lets workers watch and record how it works in real time. This helps them fix problems fast. The machine helps engineers test and solve issues quickly. Automation keeps things steady and helps factories get better.

- Case studies show many good things:

- Automated forging cells help make more products and keep quality high.

- Automation keeps work steady and finds mistakes.

- Managers need to know about automation for it to work well.

- Money matters, like payback time, are important when buying machines.

- Machine learning helps projects work better and faster in real factories.

- Real examples from health, security, and money show that learning and changing help automated systems do well.

User Feedback

Manufacturers like the Automated Matrix Machine because it works well and is simple to use. Many say it needs fewer workers and makes the workplace safer. Workers find the controls easy, so they learn fast. Companies like that it can change for new jobs. People often say it helps make more products and keeps quality high.

Use Cases

The Automated Matrix Machine is good for big factories and small shops. It helps make many kinds of radiator cores, even for electric and hybrid cars. The machine can switch between jobs fast, so it is good for companies that change products often. It also gives lots of data to help factories get better.

Core Fin Radiator Machine

Features

The Core Fin Radiator Machine makes hard fin shapes for radiator cores. It is fully automatic, so workers do not need to do much. The machine can make many fin patterns and core sizes, so it is good for custom and special radiators. It checks quality as it works to make sure every core is good.

Performance

This machine gives strong and steady cooling. It works well at medium and high speeds, especially with faster fans. The Core Fin Radiator Machine keeps making good products, so many companies trust it. Its strong build and smooth work help make more finished products.

Technology

The Core Fin Radiator Machine uses servo motors and PLC systems for exact control. It can watch and change how it works in real time to keep quality high. The machine is built strong and uses good parts, so it lasts long and needs little fixing. Workers can change fin types and core sizes easily, so it fits many jobs.

User Feedback

Manufacturers say the Core Fin Radiator Machine is fast and built well. Reviews say it keeps cooling steady, even when used a lot. The smooth finish and strong build make it look and feel high quality. There are not many direct reviews, but tests and reports show it works well and is reliable.

Use Cases

The Core Fin Radiator Machine is used by companies making special radiator cores for cars, factories, and high-performance needs. It is great when you need new fin shapes or must change products fast. The machine’s strong build and flexible design make it a top pick for companies that want to stand out.

Selection Criteria

Production Capacity

Production capacity is very important when picking a radiator core making machine. Companies need to make sure the machine can make enough products for their needs. Big factories need machines that work fast and make a lot. These machines must keep the same speed and make many parts without losing quality. The DAG Radiator Making Machine can make up to 600mm each minute. This helps companies finish orders on time and meet what customers want. Small shops might want machines that do less but are easier to change. Looking at how much you need to make helps you stop slowdowns and work better.

Automation Level

Automation level matters a lot in making radiators today. Fully automated machines mean workers do less by hand. This cuts down on mistakes and helps make more products. Companies that use more automation often get their money back fast.

- More than half of companies get their money back from automated testing tools in one year.

- Automation can find up to 90% more mistakes than checking by hand.

- Automation Success Rate shows how much better, cheaper, and faster things get, and if customers are happier.

- The world market for test automation could be $49.9 billion by 2025, so many people are using it.

Things like how long each job takes, how many mistakes happen, how much is made, and how steady the machine is help show if automation works well. Automated machines finish jobs faster and cost less. They also make fewer mistakes and help workers feel better about their jobs. Companies should think about these good things when picking a machine. Getting the right amount of automation helps a business grow and stay strong.

Material Compatibility

Material compatibility tells you what kinds of products a machine can make. Most radiator core making machines work with aluminum. Aluminum is light and does not rust easily. Some machines can also use copper or brass. This means they can make more types of radiators and heat exchangers. Companies should check what metals are used in the markets they want to sell to. Machines that work with many metals give more choices and help you be ready for the future. Picking a machine that can use different materials helps companies keep up with new rules and what customers want.

Customization

Customization is very important for manufacturers in 2025. Companies want machines that match their special products and ways of working. Top brands now give many choices for how you set up the machine. These choices help businesses make radiator cores that fit what they need.

Manufacturers often want machines that let them:

- Make changes for a certain use. Machines can be built for the exact radiator or heat exchanger needed.

- Make products lighter. Many companies want lighter items that are still strong. Machines now help make designs that weigh less but stay tough.

- Make heat move better. New designs help the radiator move heat well. This means cars work better.

- Test if new ideas work. Before making a lot, machines can test new designs. This helps make sure they work and are good quality.

Many companies like being able to add their own brand or labels. This helps them get noticed in a busy market. Some machines also let people change settings fast for different sizes or fin types. This makes it easy for both big factories and small shops.

Customer reviews show people are happy with machines that let them customize. Users say these features help them keep up with new market needs. They also say customization makes it simple to start new products or improve old ones.

Tip: When picking a machine, see if it has the features your products need. Customization can help your business beat others and keep up with new trends.

Recommendations

High-Volume Production

Big factories need machines that are fast and steady. The DAG Radiator Making Machine is great for this. It can make up to 600mm each minute. This machine works with core sizes from 150mm to 800mm. Its strong automation means less work for people. It keeps making products well, even during long hours. The advanced PLC control system helps companies change settings quickly. It also lets workers watch the process in real time. Many large factories pick DAG because it is reliable. They also like the good support after buying. The machine makes fewer mistakes, so there is less waste.

Note: If a factory wants to grow, it should get a machine that can make a lot and works well for a long time.

Advanced Technology

Companies that want new ideas should look at smart machines. The Automated Matrix Machine and ZPX-280 Model have the latest technology. The Automated Matrix Machine uses PLC controllers and servo motors for exact moves. It gives real-time data and finds mistakes early. This helps engineers fix problems fast and keep quality high. The ZPX-280 Model has flexible automation and safety sensors. It also has tools that help work go faster. Its technology lets workers change jobs quickly. It is easy to use with digital factory systems. Companies that want to be first often pick these machines.

- Automated Matrix Machine: Watches in real time, changes jobs fast, and keeps workers safe.

- ZPX-280 Model: Has flexible automation, smart sensors, and helps manage work well.

Best Value

Small and medium factories want good machines that do not cost too much. The Hydraulic Core Machine is a good choice for them. It works well and does not cost as much as fully automated machines. This machine can use both aluminum and brass. It can make up to 400mm each minute. The design is strong and easy to fix. Many companies like that it is simple to use. It has some automation that works well. The Core Fin Radiator Machine is also a good value. It is good for companies that need special fin shapes but do not want to spend a lot. Both machines help save money and keep products good.

Tip: When thinking about value, look at the price and how much you save later with less fixing and better work.

Small/Medium Business

Small and medium businesses need machines that are not too expensive. They also want machines that work well and can do different jobs. These companies often have small spaces and less money. Picking the right radiator core making machine is very important for them. Machines like the Hydraulic Core Machine and the Core Fin Radiator Machine are good choices. These models work well and do not cost as much as fully automated machines.

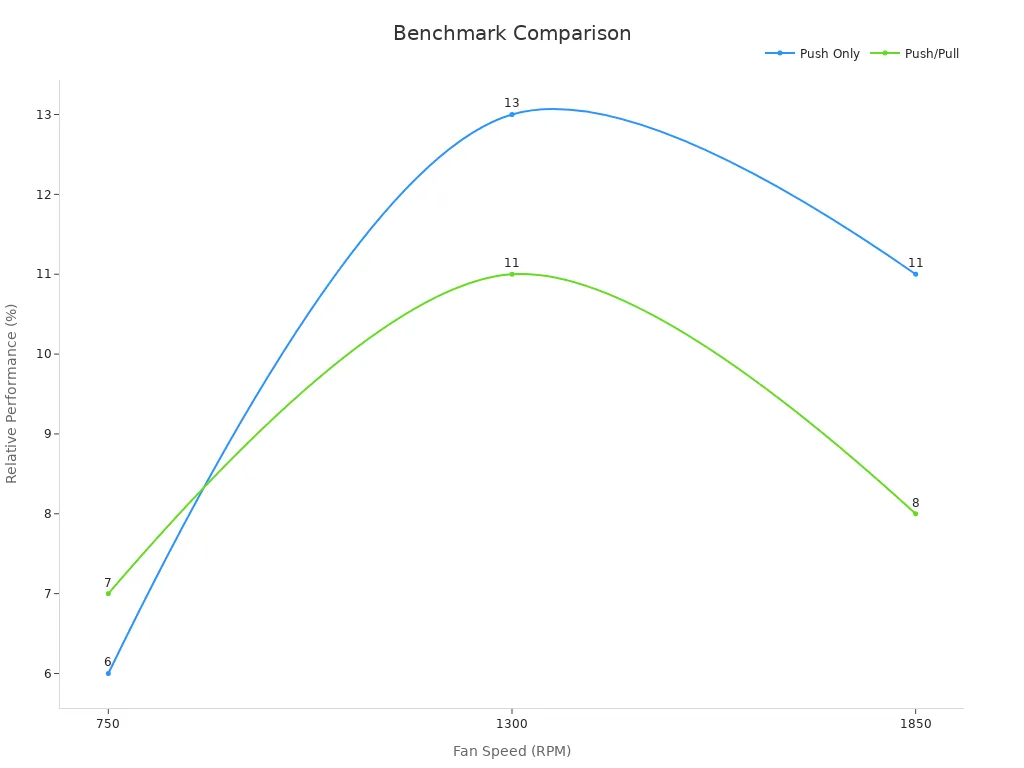

A big thing for small and medium businesses is steady cooling. The HWLabs SR2 240 MP radiator was tested at different fan speeds and setups. This shows how a good core design can give stable results. The table below shows how it works:

| Fan Speed (RPM) | Configuration | Watts Dissipated per 10°C Delta (W/10ΔT) | Performance Relative to EK XE 240 |

|---|---|---|---|

| 750 | Push Only | Works well with low fin per inch (9 FPI), almost as good as EK XE 240 but about 6% less | SR2 is a bit behind EK XE 240 but still good because the core is less tight |

| 1300 | Push Only | Keeps working well, good for slow fans | About 13% less than EK XE 240 |

| 1850 | Push Only | Not much better, but SR2 gets closer | About 11% less than EK XE 240 |

| 750 | Push/Pull | About 12% better than Push Only | About 7% less than EK XE 240 |

| 1300 | Push/Pull | Does a little worse compared to EK XE 240 | About 11% less than EK XE 240 |

| 1850 | Push/Pull | Gets a bit better but still behind | About 8% less than EK XE 240 |

This information shows that machines making radiators like the SR2 240 MP are good for small and medium businesses. The radiator works well even when the fan is slow. This saves power and makes less noise. The design lets you use different fan setups, so it is easy to change when needed.

Tip: Small and medium businesses should pick machines that are simple to set up and easy to take care of. They should also be able to make different sizes. This helps them save money and keep up with others.

Customization Needs

Customization is very important for manufacturers in 2025. Companies want machines that can change for special product designs and branding. They also want machines that fit their way of working. Top brands now have machines with settings you can change, parts you can swap, and ways to add your own brand.

Some real stories show why customization matters:

- One company got better by using a special process made just for them. The company president said this was a big reason they did well.

- New Jersey Transit Rail and Bus Operations used training made for their workers’ needs.

- The Indiana Department of Workforce Development worked with experts to make custom plans for big projects.

These examples show that custom solutions help companies fix problems and do better. Machines that let you customize help businesses try new ideas and change fast when the market changes. They also help make products that are different from others.

Manufacturers should get machines that make it easy to change product size, fin type, and branding. This helps them answer customer requests and follow new trends. Customization also helps companies make new products faster and check quality better.

Note: Buying machines with good customization features can help companies grow and stay ahead when things change.

The best machines in 2025 use automation and work fast. They also let you change things to fit your needs. Each automotive radiator core making machine has its own good points. Some are better for big jobs, while others fit small shops. You can look at the comparison to see which machine matches your goals. The next steps are simple. Make a list of what you need. You can ask DAG for a demo or ask for a special solution. Companies should think about what they need now and later. If you want expert help or a full buyer’s guide, contact us today.

FAQ

What materials do most radiator core making machines support?

Most machines use aluminum. Some can also use copper or brass. Aluminum is light and does not rust. Companies pick machines based on what metals they need.

How does automation improve radiator core production?

Automation makes work faster and more exact. It helps stop mistakes and saves money on workers. People can watch the process as it happens. Automated machines help companies make more and keep quality the same.

Can manufacturers customize radiator core making machines?

Yes, many brands let you customize. Companies can change settings for different core sizes or fin types. They can also add their own brand. Customization helps make special products and react to market changes fast.

What kind of support do manufacturers receive after purchasing a machine?

Manufacturers get help with setup, training, and fixing problems. Top brands like DAG give help all day and night. Support teams help with starting, fixing, and upgrades. This keeps machines running and stops long breaks.

How do companies choose the right machine for their needs?

Companies look at how much the machine can make and how much is automated. They check what materials it uses and if it can be customized. They also think about support and price. Looking at these things helps pick the best machine.

Are these machines suitable for small and medium businesses?

Yes, many machines are good for small and medium businesses. Some cost less and have flexible features. These machines help smaller companies make good radiator cores without spending a lot.

How often do machines require maintenance?

Most machines need regular care to work well. Companies should check and clean them on a schedule. Taking care of machines helps them last longer and break less.

Tip: Always use the maker’s guide for taking care of your machine.