Introduction to Car Radiator Fin Forming Machines

As an industry insider, I’m always fascinated by the technological marvels that revolutionize our work. One such game-changer is the Car Radiator Fin Forming Machine. These machines play a pivotal role in producing car radiators, a critical component for vehicle performance.

The Car Radiator Fin Forming Machine creates the delicate and intricate fin patterns seen on radiator cores. These fins are crucial for the radiator’s function, as they enhance the surface area for heat to dissipate, thus maintaining the engine’s temperature. Creating these precise and consistent fins would be daunting without this machine.

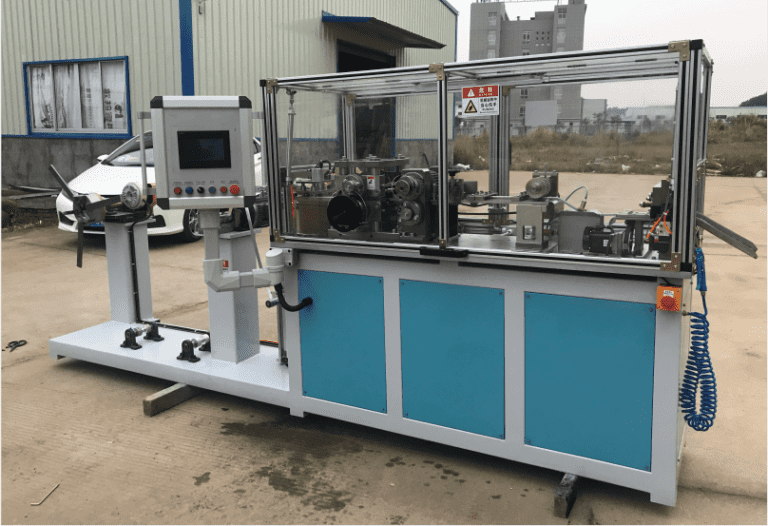

The technology behind these machines is continually evolving, making them more efficient and reliable. The introduction of automated systems and computerized control panels has made these machines easier to operate, reducing human error and increasing productivity.

The Role of Car Radiator Fin Forming Machines in the Automotive Industry

As we delve deeper into the subject, we’ll understand these machines’ role in the automotive industry. The Car Radiator Fin Forming Machine is not just a tool; it’s an integral part of the radiator production process. Without it, we wouldn’t have the efficient cooling systems we see in vehicles today.

The machine’s role goes beyond shaping the radiator fins. It determines the radiator’s performance and efficiency, influencing the vehicle’s overall performance. The machine’s precision allows for consistent fin formation, directly affecting the radiator’s heat dissipation capacity.

In the highly competitive automotive industry, these machines provide an edge by ensuring the production of high-quality radiators. Manufacturers who invest in advanced Car Radiator Fin Forming Machines can guarantee better product quality, giving them an advantage in the market.

Understanding the Car Radiator Fin Forming Process

The Car Radiator Fin Forming process may seem complicated, but it’s a marvel of engineering simplicity. The machine takes a strip of aluminum or copper and feeds it into the machine, and it’s then meticulously folded into precise fins. The process requires a delicate balance of force and control to ensure the fins aren’t damaged during formation.

The machine uses a set of rollers to feed the metal strip into the fin-forming section. Here, a series of tools shaped to match the desired fin pattern bends the strip into the fins. The machine then cuts the fins into the required length. The entire process is automated, ensuring consistency and accuracy.

The Car Radiator Fin-Forming process is a true testament to human ingenuity. It takes a simple concept—increasing surface area for better heat dissipation—and turns it into an intricate and precise manufacturing process.

Benefits of Using Car Radiator Fin Forming Machines

The benefits of using car radiator fin-forming machines are manifold. First, these machines ensure the production of high-quality radiators. The precise fin formation enhances the radiator’s performance, leading to better vehicle performance.

Second, these machines are highly efficient. They significantly speed up the production process, allowing manufacturers to meet high demand. Automation also reduces human intervention, minimizing the chances of errors and defects.

Third, Car Radiator Fin Forming Machines are adaptable. They can accommodate different materials and fin designs, making them versatile. This adaptability allows manufacturers to create custom radiators for specific vehicle models or applications.

Innovations in Car Radiator Fin Forming Machines

Innovation is the heart of progress, and the Car Radiator Fin Forming Machine is no different. Over the years, these machines have seen significant advancements, making them more reliable, efficient, and user-friendly.

One such innovation is the introduction of computerized control systems. These systems allow operators to input the desired fin pattern and material thickness, and the machine does the rest. This technology has made these machines easier to operate, reducing the learning curve for new operators.

Another notable innovation is the integration of quality-checking systems. These systems automatically check the produced fins for defects or inconsistencies. If any are detected, the machine automatically stops, preventing the production of defective radiators.

The Impact of Car Radiator Fin Forming Machines on the Automotive Industry

The impact of Car Radiator Fin Forming Machines on the automotive industry cannot be overstated. These machines have made it possible to produce high-quality radiators on a large scale, meeting the increasing demand for vehicles.

Furthermore, the precision and consistency provided by these machines have produced more efficient radiators. This efficiency has, in turn, led to better-performing vehicles. In essence, Car Radiator Fin Forming Machines have played a significant role in the overall improvement of vehicles.

Moreover, these machines have also led to cost savings. Their automation and speed have reduced labor costs and increased production speed, leading to higher manufacturer profit margins.

Case Study: Successful Implementation of Car Radiator Fin Forming Machines

One notable example of the successful implementation of Car Radiator Fin Forming Machines is a leading car manufacturer. Faced with increasing demand and the need for better-quality radiators, they invested in advanced Car Radiator Fin Forming Machines.

The result was impressive. They were able to increase production speed significantly, meeting the high demand. Furthermore, the radiators produced were of better quality, leading to better vehicle performance and fewer customer complaints.

This case study is a testament to the impact these machines have on a manufacturer’s production capacity and product quality.

Future Trends in Car Radiator Fin Forming Technology

The future of Car Radiator Fin Forming Technology looks bright. With technological advancements constant, we can expect these machines to become even more efficient and reliable.

One possible trend is the integration of AI technology. AI could be used to optimize the fin-forming process, resulting in even better-quality fins. It could also predict maintenance needs, reduce machine downtime, and increase productivity.

Another trend could be the use of more environmentally friendly materials. As the automotive industry moves towards more sustainable practices, car radiator fin-forming machines can adapt to work with these new materials.

Finding the Right Car Radiator Fin Forming Machine for Your Business

There are several factors to consider if you’re in the market for a Car Radiator Fin Forming Machine. First, consider the machine’s capacity. Make sure it can meet your production demand.

Second, consider the machine’s versatility. Can it accommodate different materials and fin designs? This versatility can be crucial if you plan to produce custom radiators.

Lastly, the machine’s reliability and after-sales service should be considered. A reliable machine will save you from costly downtime. Good after-sales service, on the other hand, will ensure that any issues are promptly addressed.

Conclusion: The Future of the Automotive Industry with Car Radiator Fin Forming Machines

In conclusion, Car Radiator Fin Forming Machines have revolutionized the automotive industry. They have made it possible to produce high-quality radiators efficiently and consistently. The innovations in these machines have made them even better, and the future promises even more advancements.

As the automotive industry evolves, these machines will play a significant role. They will continue to drive the production of better radiators, leading to better vehicles. The future of the automotive industry with Car Radiator Fin Forming Machines is undoubtedly bright.