Shenzhen DaG Radiator Machine Co., Ltd

Our company has been manufacturing and developing automobile radiator condenser production equipment for over ten years. Most products are sold to all countries and regions worldwide and have accumulated rich production experience.

With the development of the heat switch industry, more countries and regions are committed to building a local car radiator condenser manufacturer. In recent years, companies in the same sector in many countries and regions have also purchased radiator core assembly machines, manifold automatic slotting machines, plastic water chamber crimping machines, radiator fin forming machines, and other mechanical equipment from us.

If you want to establish a radiator factory at your location, please contact us. We will provide you with the best service.

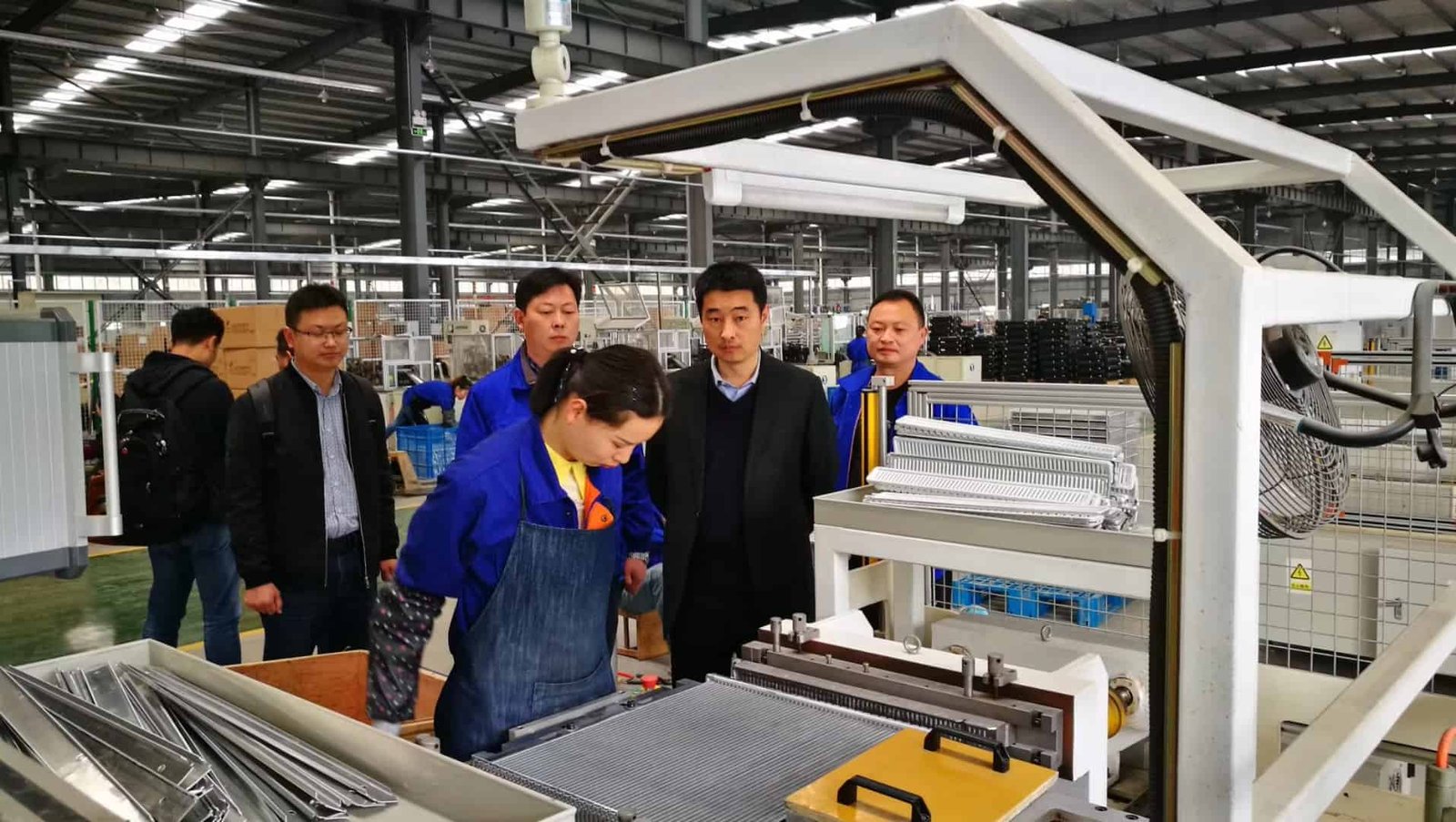

Our Team

Sales Team

Our company has provided radiators, air-conditioning condensers, parts, and machines for over ten years. To retain all sales and think that all customers provide good services, we have invested in many technology and project management services. You can only communicate with customers steadily through the mail, Skype, and telephone. We provide customers with pre-and after-sales equipment design and services.

Technical Team

We offer customizable options to tailor our machines to your needs, ensuring they fit your production process perfectly. We’ll have technicians on site to guide installation and provide comprehensive support and training resources to ensure you maximize the potential of our machines and achieve the best results in your manufacturing operations.

Quality Team

We use high-precision measuring tools and equipment to ensure that every product our machines produce is of exceptional precision and accuracy and meets the highest quality standards. Thus, we increase your manufacturing operation’s efficiency, accuracy, and productivity.

Service Team

We insist on being customer-centric and operating with integrity. We insist that quality is the foundation and win-through service. For the past five years, we have been helping foreign customers set up regional radiator factories. We provide customers with pre-sale and after-sale equipment design and service according to the size of our products. We will send technicians to guide the installation on-site to ensure the smooth production of the customer’s factory and provide free consultation service in case of any doubt in the production process.

Believe in us; not only is what you get in the product, but we are also committed to guaranteeing it!