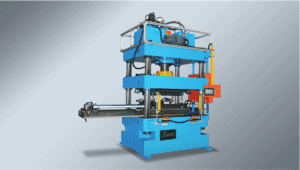

Machine Description

| Machine Name: | Radiator Making Machine | Working Principle : | Hydraulic; 4-column Structure; PLC Controlled |

| Driving Force: | Hydraulic And Pneumatic | Type: | Servo |

| Power: | 7.5KW | Weight: | 4Ton |

| High Light: | radiator production line, radiator tube-making machine | ||

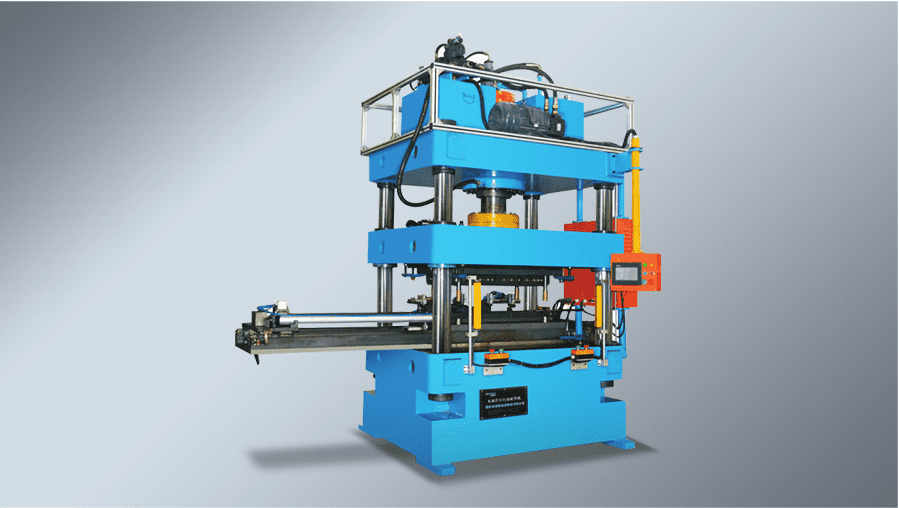

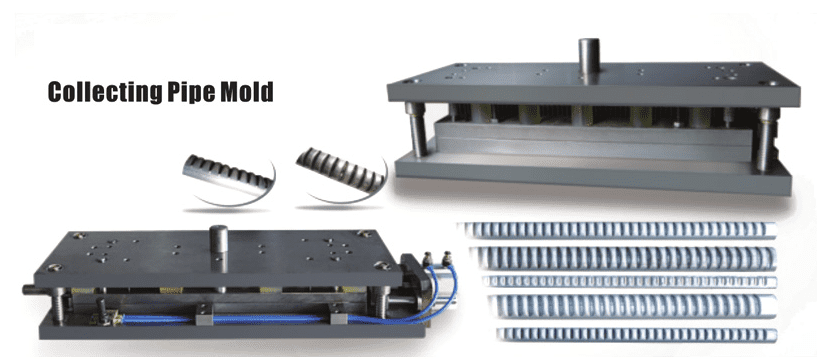

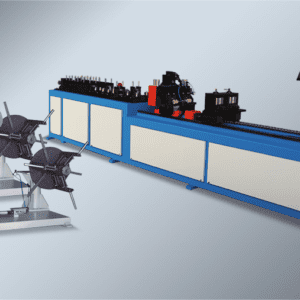

Collecting Pipe Auto Punching Forming Machine

This specialized machine is engineered for parallel flow condenser header production, processing aluminum tubes via automated punching. It serves as critical equipment in parallel flow condenser assembly lines, manufacturing both circular headers and profiled/shaped headers with high accuracy.

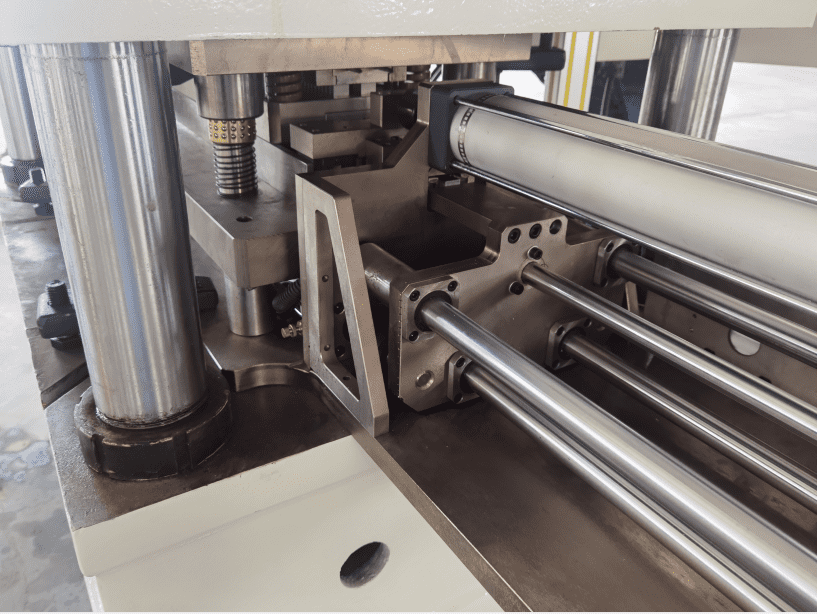

1. Drive System: High-performance hydraulic power unit with integrated automatic lubrication

2. Frame Construction: Robust four-column structural design ensures maximum stability and punching precision

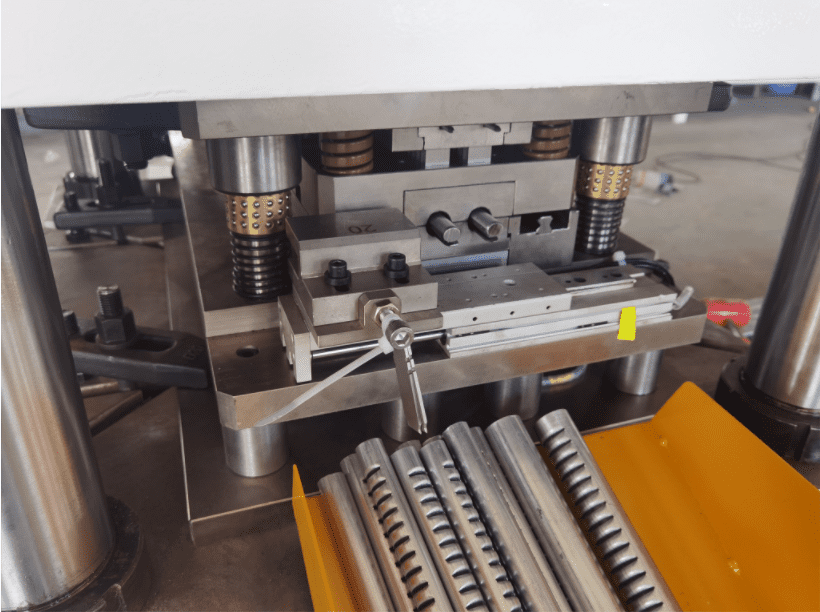

3. Quick-Change Tooling: Equipped with die assembly/disassembly slide rails for rapid mold replacement and minimal downtime

4. Processing Method: Precision punching operation for consistent hole quality

Machine Technical Parameters

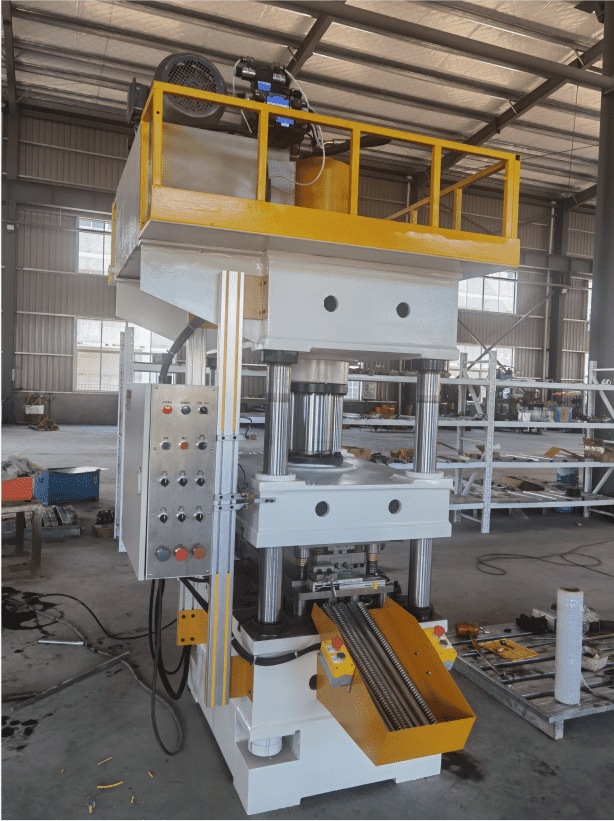

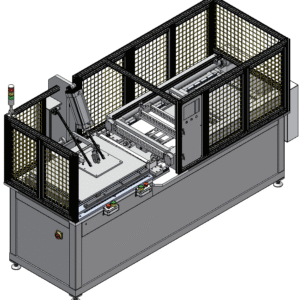

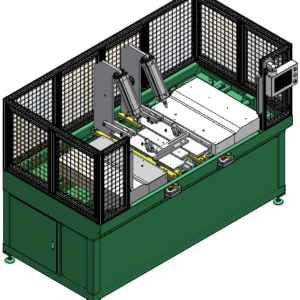

Automatic Condenser Header Tube Punching Forming Machine

| Working method | manual feeding, automatic forming, and discharging |

| Collecting pipe to be produced per time | One pipe |

| Pipe outer diameter* wall thickness | according to the customer’s requirement |

| Pipe effective length | 200-650mm |

| Slot center-to-center distance and tolerance | 5~12mm; ±0.05 mm |

| Slot forming time | 20 seconds per pipe |

| Total power | 7.5KW |

| Hydraulic system working pressure | 8-21Mpa |

| pneumatic system working pressure | 0.5-0.8Mpa |

| overall dimension | 2500mm×2100mm×2750mm |

| equipment weight | 4T |

Condenser Header Pipe Punching Machine

This specialized header punching machine performs precision hole punching on aluminum tubes to manufacture headers for parallel flow condensers. As essential equipment in parallel flow condenser production lines, it efficiently produces both circular headers and profiled/shaped headers.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.