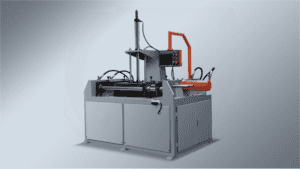

Machine Description

| Machine Name: | Radiator Making Machine | Radiator Type: | Mechanical |

| Aluminum Pipe: | 8mm Dia | PLC Brand: | Delta, Taiwan |

| Power: | 7.5KW | Electrical Control System: | PLC And HMI |

| High Light: | radiator manufacturing equipment, radiator production line | ||

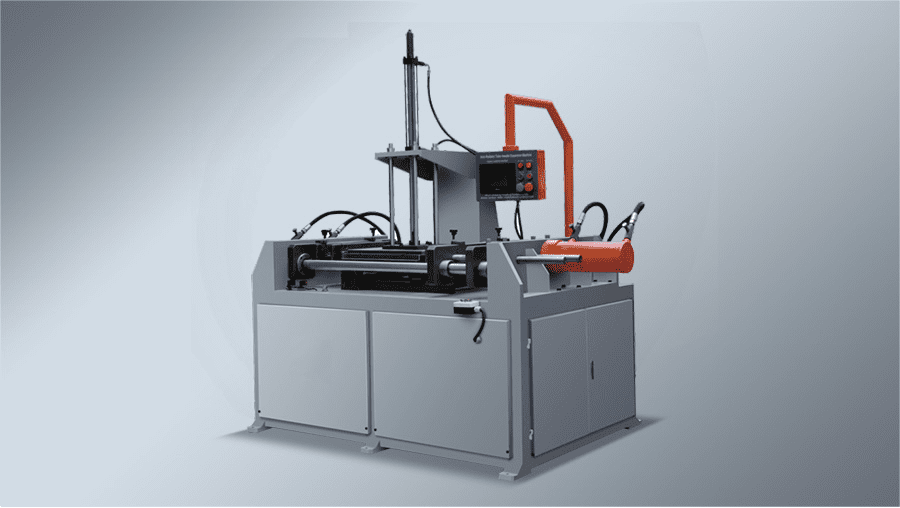

Aluminum Tube Expanding Machine

Our Tube End Expanding Machinefeatures dual control modes—automatic and manual—for operational flexibility. The electrical control system utilizes a PLC controller to ensure precise, repeatable tube expansion cycles. Powered by a robust hydraulic drive system, this machine delivers consistent force and stroke control. Tooling changes for different tube specifications are quick and effortless, minimizing downtime and maximizing productivity.

Key Features

1. Dual-mode operation: Automatic & manual control

2. PLC-based control system for precision process management

3. Hydraulic power drive for reliable, high-force output

4. Quick-change tooling system for seamless model transitions

Machine Technical Parameters

| Core dimension | Core height direction:350-780mm |

| Core Width direction:200-680mm | |

| Hole flaring specification | as per the Customer’s requirements |

| Pipe Hole Quantity | as per the Customer’s requirements |

| Precision Tolerance Rangethe | as per Customer’s requirements |

| Pipe Processed per time | 1 Set/Cycle |

| Production capacity | Around 240 Sets/Hour |

| Drive mode | Servo/Pneumatic Hydraulic/Pneumatic(Optional) |

| Overall Dimension | 2800*1500*1700mm |

| Weight | 2.3 T |

Aluminum Tube Expanding Machine

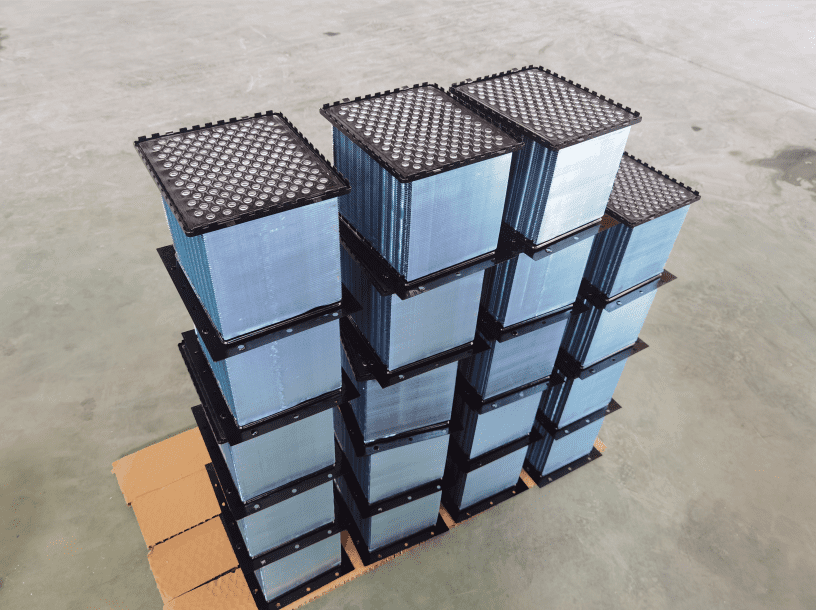

Mechanical Radiator Manufacturing Equipment includes tube expansion machines that precisely flare tube ends, creating a secure, leak-proof mechanical connection between header plates and aluminum tubes. Tube expanding is a critical manufacturing step in producing high-performance mechanical aluminum radiators. Made in China. Fully customizable specifications. Complete technical support provided. Competitive factory-direct pricing. Request a detailed quote today.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.