Machine Description

| Name: | Radiator Plastic Tank Crimping Machine | Power Supply: | 3P 380V 50HZ (customized) |

| Core Components: | PLC, Motor | Air Source: | 0.6MPa |

| Radiator Core Width: | 350-950mm | Header Plate Width: | 30-120mm (customized) |

| High Light: | Aluminum Radiator Plastic Tank Crimping Machine, Radiator Clinching Machine | ||

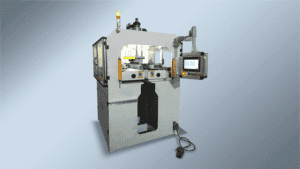

110mm Max Core Height Truck Aluminum Radiator Plastic Tank Crimping Machine

Professional-grade radiator plastic tank crimping machine specifically engineered for truck applications with maximum 110mm core height capacity. This versatile assembly system delivers precision and flexibility for low-to-medium volume production environments.

Technical Specifications & Operational Features

1. Streamlined Operation: Requires minimal operator training—workforce can achieve proficiency through short-term instruction, reducing onboarding time and labor costs.

2. Low-Volume Optimization: Ideal for small-batch production and single-model radiator tank installations, providing cost-effective solutions for specialized manufacturing.

3. Simplified Maintenance: Designed for easy daily upkeep with minimal service requirements, ensuring maximum equipment uptime and reduced operational expenses.

4. Manual Adjustable Configuration: Work positions and operating tools can be manually reconfigured to accommodate various radiator tank structures and dimensions without complex reprogramming.

5. Flexible Workforce Allocation: Supports both single-operator and dual-operator simultaneous operation modes, optimizing labor efficiency based on production demands.

6. Post-Extraction Manual Compression: Features manual side-end compression capability after core removal, allowing for precise finishing control.

7. Interchangeable Clamping System: Offers multiple press plate width options to handle diverse radiator specifications and design variations.

8. Adjustable Manipulator Parameters: Robotic arm stroke length and compression force can be manually calibrated as needed, ensuring consistent quality across different product configurations.

Machine Technical Parameters

Aluminum Radiator Plastic Tank Crimping Machine

| Radiator height | 350-950mm |

| Radiator max width | 100-800mm |

| Crimping way | stepping way |

| Production capacity | about 24 cores per hour |

| Driving force | servo + pneumatic |

| Crimped teeth quantity | max 100 pieces |

| Total power | 1.5kw |

| Voltage grade | 3P 380V 50HZ |

| Overall dimension | 2200×2000×1900mm (L*W*H) |

| Weight | 1.8Ton |

Service & Support

1. Customized Pre-Sales Solutions: Before formal contract signing, we analyze your project specifications to deliver professional, optimized solutions.

2. 24-Hour Response Guarantee: All product and pricing inquiries receive a guaranteed reply within 24 hours.

3. Production Transparency & QA Support: We provide continuous production progress updates and assist with factory quality inspection arrangements when necessary.

4. One-Year Manufacturer’s Warranty: Comprehensive 12-month warranty coverage on all equipment.

5. Complimentary Technical Training: Buyers may send technicians to our factory for free training prior to delivery.

6. Emergency Technical Support: For critical equipment failures, we dispatch engineers on-site for troubleshooting while providing ongoing online technical support throughout the resolution period.

Truck Aluminum Radiator Plastic Tank Crimping Machine

The radiator plastic tank crimping machine integrates the radiator core's main board, sealing gasket, and plastic water chamber into a single sealed assembly. The process mechanically bends pre-formed "Great Wall teeth" or tabs on the main board to securely hook onto the water chamber's edges, creating a leak-proof container through compression and deformation. This truck radiator plastic tank crimping machine, designed and manufactured by Shenzhen DAG, is highly competitively priced. Request a detailed quote now.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.