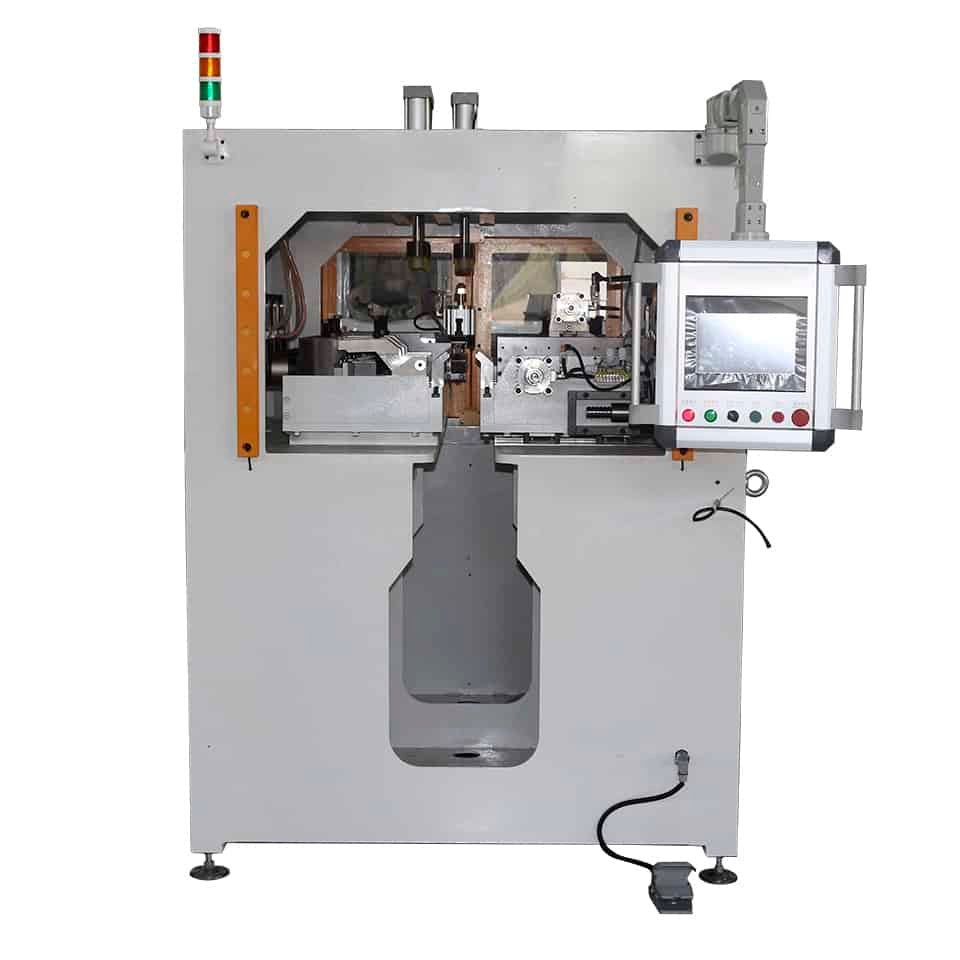

Machine Description

| Machine Name: | Plastic Tank Crimping / Clinching Machine | Weight: | 3200kgs |

| Driving System: | Hydraulic + Pneumatic | Overall Size: | 2200*2000*1900mm |

| High Light: | automatic crimping machine, radiator tank crimping tool | ||

Four-Side Crimping Radiator Plastic Tank Press Machine

This high-precision four-side crimping radiator plastic tank press machine is engineered to crimp the header tabs and securely lock plastic tanks onto radiator cores. The crimping process creates a sealed chamber between the plastic tank, gasket, and header plate, ensuring leak-proof performance for automotive cooling systems.

Key Applications & Features

– The plastic tank clinching machine is PLC-controlled, and the crimping program is set up through the touch screen.

-The touch screen can indicate the working status and the control system stores radiator crimping parameters.

– Precision Crimping Technology: Forms uniform, distortion-free crimps on all four sides of the radiator header

-The plastic tank crimping machine can crimp the header at four sides in one cycle.

– Secure Tank Assembly: Permanently attaches plastic tanks to aluminum cores

– Sealed Joint Formation:Compresses the gasket to create a reliable, high-pressure seal

– Automotive-Grade Performance:Meets OEM specifications for radiator manufacturing and aftermarket repair

Equipment Benefits

– All-side synchronous crimping ensures consistent seal integrity

– Adjustable crimping force accommodates various radiator sizes

– Ideal for plastic tank radiators in passenger vehicles, trucks, and heavy-duty equipment

Machine Technical Parameters

| Core Size | Header-to-header distance | 350-950mm |

| Header length | 100-800mm | |

| roductivity | Cores per hour | |

| Working Mechanism | hydraulic and pneumatic | |

| Overall Dimension | L, W, H | 2200*2000*1900mm |

| Machine Weight | Net Weight | 3200kg |

Radiator Plastic Tank Crimping Machine For 4 Sides

This precision-engineered radiator plastic tank crimping machine permanently secures plastic tanks to radiator cores through advanced header plate tab crimping technology. The system integrates the radiator core header, sealing gasket, and plastic tank into a high-integrity, leak-proof assembly. This machine can process radiators of various sizes and structures and features quick mold changes, making it suitable for automotive and industrial applications. - Passenger vehicle and commercial truck radiator assembly - Agricultural and construction equipment cooling systems - Industrial heat exchanger manufacturing - OEM and aftermarket radiator production

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.