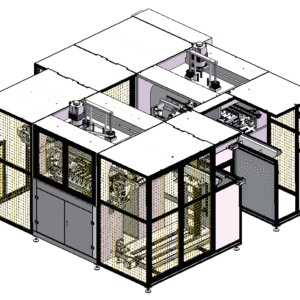

Machine Description

| Machine Name: | Radiator Plastic Tank Crimping Machine | Type: | Servo And Pneumatic |

| Color: | Customized | Power: | 2.5KW |

| Cycle: | 300 Cores Per 8 Hours | Warranty: | 1 Year |

| High Light: | Automatic Crimping Machine,Radiator Tank Crimping Tool | ||

Servo Type Radiator Plastic Tank Crimping Machine

1. The radiator plastic tank crimping machine drives the left and right crimping device forward through the ball screw driven by the servo motor.

2. The equipment is PLC controlled, and the crimping program is set up through the touch screen.

All crimping sequences are programmed through a color touchscreen that displays real-time machine status and stores individual parameters for every radiator model.

3. The equipment has functions such as plastic tank water inlet dodge and virtual travel speed-up, making it suitable for crimping of plastic tanks and header plates of different specifications.

4. The radiator plastic tank crimping machine is divided into a long header and a short header crimping mechanism which separately crimps the long header plate and the short header plate.

engineered for high-precision, leak-free crimping of plastic tanks to aluminum cores in automotive and industrial heat-exchanger manufacturing.

Machine Technical Parameters

| ax radiator size | 850*1000*140mm (header length, header to header distance, and header width) |

| Step distance | adjustable |

| Crimped teeth quantity | max 110 pieces |

| Safety device | photoelectric light curtain |

| Voltage | 380V; 3P;50Hz |

| Rated power | 2.5kw |

| Working pressure | max 0.6Mpa (pneumatic) |

| Overall dimension for reference | 1900×1600×1800mm (L*W*H) |

| Average hourly output | about 300 cores crimped per 8 hours (decided by product specification and individual worker speed) |

Servo Type Radiator Plastic Tank Crimping Machine

This radiator plastic tank clinching machine is engineered to fold the header-plate tabs over the tank flange with controlled force, permanently locking the plastic tank, EPDM gasket and aluminum header into a uniform, void-free seal cavity. Servo-driven or hydraulic crimping modules guarantee repeatable tab penetration depth and 360° uniform compression, eliminating micro-leak paths and guaranteeing long-term pressure integrity for automotive and heavy-duty heat-exchanger assemblies.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.