Product Introduction

Continuous High Temperature Brazing Furnace

The continuous high-temperature brazing furnace is an industrial equipment used for non-oxidation brazing and bright heat treatment of metal materials. It uses the hydrogen decomposed by the ammonia decomposition equipment and the purified hydrogen-nitrogen mixed gas as a protective atmosphere for continuous brazing and bright annealing. It is mainly used for continuous brazing and bright treatment of iron-based workpieces, copper-based workpieces, and stainless steel workpieces.

High-Volume Applications

1. Ferrous parts: fuel-rail assemblies, hydraulic fittings, brake lines, transmission oil coolers.

2. Copper and brass components: electrical connectors, heat-exchanger headers, HVAC distributors.

3. Stainless-steel assemblies: medical instrument joints, food-grade tube manifolds, sensor housings.

4. Typical filler metals: copper, nickel-base, silver, and copper-phosphorus alloys; joint gaps 0.02–0.1 mm optimized for capillary flow.

Device Parameters

| Model | Rated power (kw) | Heating zone (set) | Heating zone size L*W*H (mm) | Effective cooling length (mm) | Heating time (h) | Empty furnace loss (kw) | Yield (kg/h) | Ammonia decomposition ability (m³/h) |

| HCS8-20 | 30 | 3 | 2000*200*60 | 4800 | ≤3 | 9 | 40 | 4.5 |

| HCS12-15 | 45 | 3 | 2600*155*50 | 6800 | ≤3 | 10 | 50 | 3.8 |

| HCS16-20 | 60 | 4 | 3500*200*60 | 9000 | ≤3.5 | 15 | 80 | 4.5 |

| HCS16-30 | 85 | 4 | 3500*300*80 | 9000 | ≤4 | 20 | 120 | 5 |

| HCS20-35 | 120 | 5 | 4500*350*120 | 11800 | ≤4.5 | 30 | 200 | 10 |

Equipment specifications and dimensions can be customized to meet your specific requirements.

Main Components

Components of a continuous high-temperature brazing furnace: A Continuous high-temperature brazing furnace consists of a feeding section, a preheating section, a heating furnace body, a cooling section, a discharging section, an electrical control system and an ammonia decomposition furnace.

Working Principle

Continuous High Temperature Brazing Furnace

The metal workpiece is driven by a stainless steel mesh belt. The workpiece is placed on the mesh belt and enters from the preheating section. It is transported by the mesh belt and is preheated, heated by melting the brazing material, and cooled. The workpiece discharged from the cooling section of the continuous high temperature brazing furnace is protected by hydrogen gas in the continuous high temperature brazing furnace. Due to the reducing nature of hydrogen, the surface of the product is bright and does not oxidize. The workpiece welding is carried out by heating the workpiece.

Main Equipment

The continuous high-temperature brazing furnace device is mainly composed of a transmission system, a heating system, a cooling system, a control system, and an ammonia decomposition gas supply system.

The muffle furnace is constructed from imported, high-temperature-resistant nickel alloy, pressure-welded. The removable electric heating element allows for upward and downward heating. The steel belt conveyor features stepless speed regulation, and the gas mixture (75% hydrogen, 25% oxygen) derived from the decomposition of liquid ammonia enters the furnace, providing a protective atmosphere. A gas flow control device ensures a stable atmosphere. After treatment in this furnace, the product surface becomes shiny and resistant to oxidation.

Application Cases

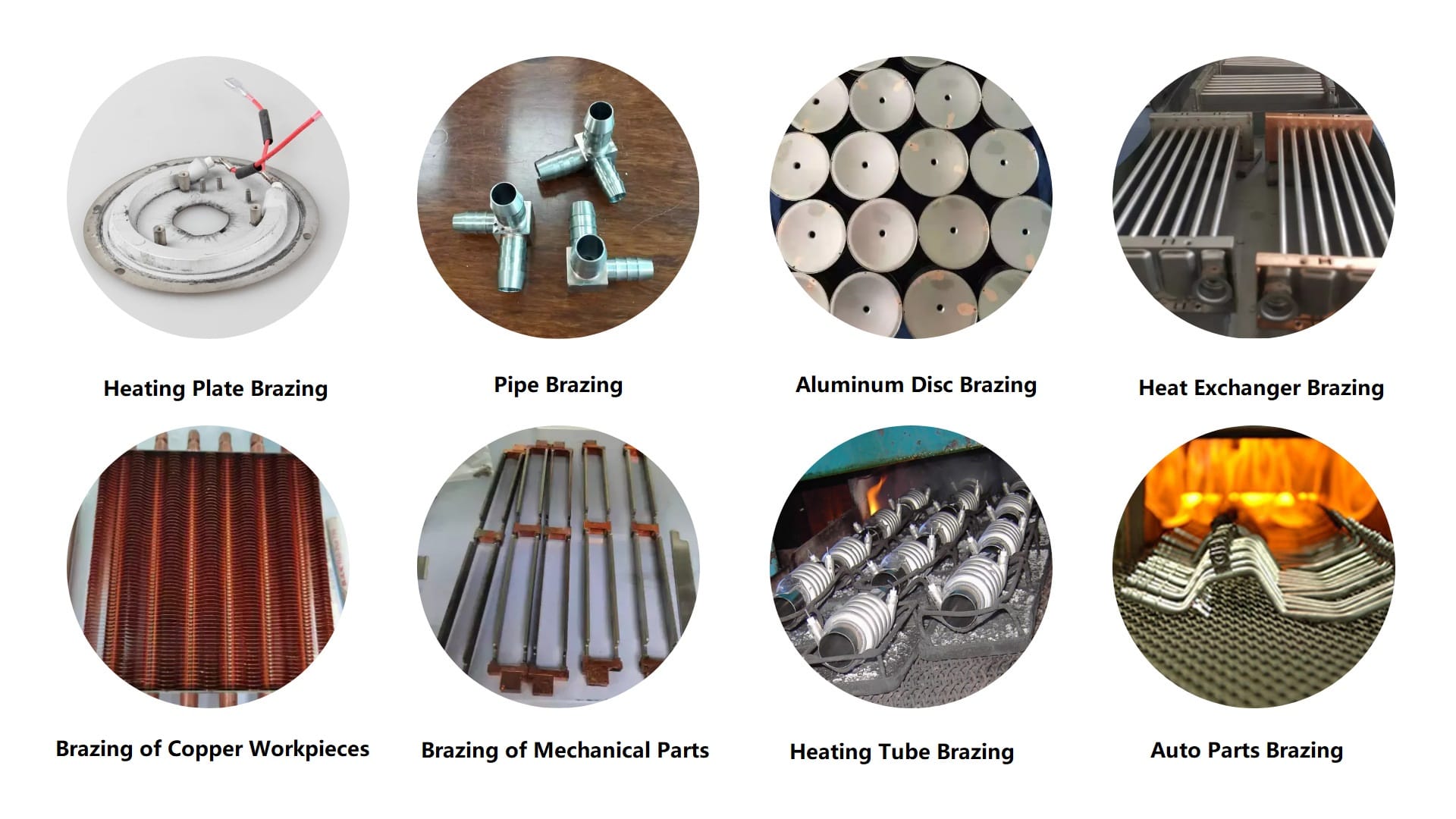

High temperature brazing samples

Continuous High Temperature Brazing Furnace

The continuous high-temperature brazing furnace device is mainly composed of a transmission system, a heating system, a cooling system, a control system, and an ammonia decomposition gas supply system. We can customize our products to meet your needs and budget at competitive prices. Inquiries are welcome, and we look forward to long-term partnerships. On-site Installation. Commissioning.Operator Training.Global Industrial Furnace Supplier. Get a Quote Now.

Product SKU: 2

Product Brand: DAG

5