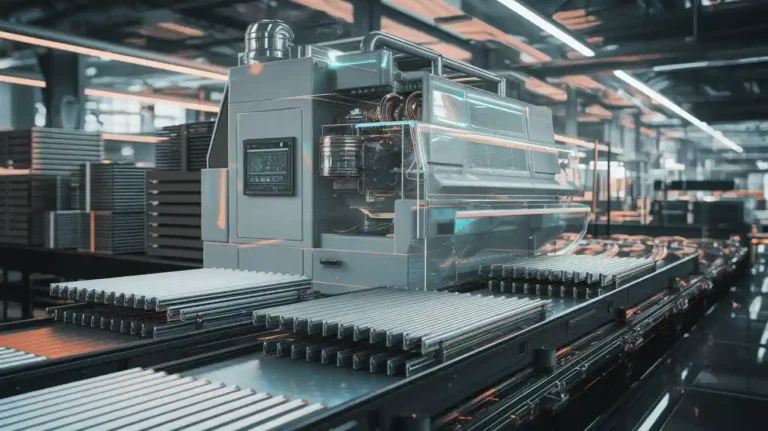

Radiator fin machines are important in today’s factories. These machines make metal fins for radiator systems fast and well. Companies want things like PLC controls and servo motors. These help make every fin the same size each time. DAG is known around the world for its special machines. Their machines use touch screens and smart controls. Many people in Europe, Egypt, and Iran trust DAG. They know DAG gives good radiator fin machine solutions.

Key Takeaways

- Radiator fin machines make metal fins fast and exact. This helps radiators work better and get made quicker.

- These machines can make straight, wavy, or louvered fins. Each fin type helps with different cooling jobs.

- New machines use smart controls and automation. This cuts down on waste and saves money on workers. It also keeps production steady.

- Aluminum and copper are used for fins. These materials change how well fins work. Machines can use both to fit different cooling needs.

- Roll forming and feeding systems shape fins strongly. They also keep fin sizes the same. This helps fins move heat better.

- Radiator fin machines are used in many fields. Some are cars, HVAC, power plants, and electronics.

- Factories can change fin types and sizes easily. This helps them keep up with what customers want.

- Good support services help machines work well. Training and tech help stop machines from breaking down.

Unique Features

Radiator fin machines stand out because they offer a range of features that help factories make better products faster. Let’s look at what makes these machines special.

Fin Types

A fin press can create many different fin shapes. Each type has its own job in cooling systems. Here are some of the most common fin types:

Straight Fins

A fin press makes straight fins, also called plain fins. These fins have a simple, flat shape. They allow air or liquid to move easily through the radiator. Straight fins work well when low flow resistance is important, such as in liquid cooling or phase change systems. They do not block air or fluid, so they help keep the system running smoothly.

Wavy Fins

A fin press can also make wavy fins. These fins have a curved shape that forms channels for air or fluid. Wavy fins help by increasing turbulence. This means the air or liquid moves around more, which helps with enhancing heat transfer. Wavy fins also resist getting blocked by dirt or debris, so they stay effective longer.

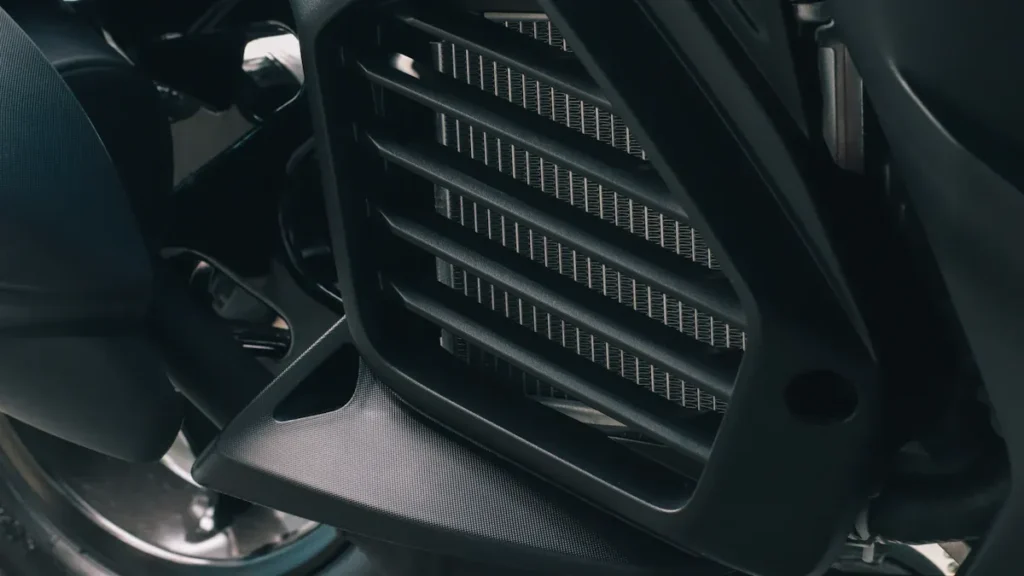

Louvered Fins

Louvered fins are another option from a fin press. These fins have small cuts that look like shutters. The cuts help mix the air or fluid, which boosts heat transfer. Louvered fins are common in cars and trucks because a fin press can make them quickly. They work well in mass production, even though they can collect dirt over time.

Tip: Using the right fin type can make a big difference in how well a radiator works. Factories often choose the fin shape based on the cooling job they need to do.

Material Options

A fin press works with different metals. The most common choices are aluminum and copper. Aluminum is light and resists rust. This makes it good for truck radiators and places where weight matters. Copper is heavier but moves heat better than aluminum. Some fin presses use copper for jobs that need fast heat movement. The choice of material affects how long the radiator lasts and how well it cools.

- Aluminum fins are strong and do not rust easily. They work well in tight spaces and can handle stress from heat.

- Copper fins move heat quickly. They are heavier and cost more, but they help cool things down fast.

- The space between fins also matters. A fin press can make fins with 5mm spacing. This close spacing gives more surface area for cooling and makes the radiator stronger.

Automation

Modern fin press machines use smart technology to help factories work faster and better. Automation brings several benefits:

- A fin press can make fins at speeds up to 300 meters per minute. This means more radiators in less time.

- Automation helps cut each fin to the right size every time. This keeps the radiator working well.

- Some fin presses use machines that put fins and tubes together. This reduces the need for workers and lowers mistakes.

- When factories use automated fin presses, they save money on labor and waste less material.

- Automation makes the whole process smoother and helps factories keep up with big orders.

| Performance Metric | Fin Press with Modern Features vs Traditional Equipment |

|---|---|

| Heat Transfer Efficiency Increase | 5.77% to 8.23% higher |

| Mechanical Strength | 70% stronger |

| Pumping Power Reduction | Up to 54.9% less |

| Production Speed | Up to 300 meters/minute |

A fin press with these features helps factories make radiators that last longer and cool better. The machines also help save money and time, making them a smart choice for many industries.

Radiator Fin Machine Working Principle

Roll Forming

A radiator fin machine shapes metal sheets using roll forming. It starts with aluminum sheets. The machine rolls these sheets to the right thickness. Workers cut the sheets into strips. The strips go through rollers. The rollers make zigzag or wavy shapes. This step makes more surface area. More surface area helps heat move better. The last rolling step gives the fins their final shape.

- The rollers have a special design. They control how thick, spaced, and flat the fins are.

- The rollers have textured surfaces. These help grip the metal and keep the shape.

- The machine works fast and stays steady. Every fin looks the same.

- Rolling makes the metal stronger and less porous. Fins last longer and work better.

Note: Roll forming helps the radiator fin machine make fins that are strong and good at moving heat.

Feeding Systems

Feeding systems help the fin press keep working. The machine pulls metal strips from a coil. It feeds them into the rollers at a steady speed. This keeps things smooth and stops jams.

- Motors and gears move the strips.

- Sensors check where the metal is and how fast it moves.

- The system changes the feed rate for different fin types.

- Feeding systems let the fin press use many materials, like aluminum and copper.

A good feeding system means less waste and fewer mistakes. The radiator fin machine can run for a long time without stopping.

Control Technology

Control technology makes the radiator fin machine easy to use. Many machines use PLC systems and servo motors. Operators set what they want on a touchscreen. The machine follows these settings for every fin.

- PLC controls what the equipment does.

- Servo motors and encoders keep things accurate.

- The system switches between fin models by itself.

- Hydraulic-driven rolls work with servo motors for smooth movement.

This technology helps the fin press make fins with exact sizes. The machine does not need much help from people. Production stays quick and steady. Operators can change settings fast for new jobs.

Tip: Advanced control technology helps factories fill big orders and keep quality high.

Advantages

Speed

Radiator fin machines work very quickly. They can make lots of fins in one minute. This helps factories finish big orders fast. Workers do not have to wait long for each batch. DAG’s machines can go up to 280 meters per minute. This lets companies make more radiators every day.

- Fast machines help finish work on time.

- Quick production keeps things moving.

- Less waiting means more products are ready.

Tip: Fast machines help companies beat their competition.

Precision

Every fin needs to look the same. Radiator fin machines use smart controls for this. PLC systems and servo motors keep the size and shape right. The machine checks each step and fixes small mistakes. This keeps errors low.

- Machines use sensors to check the metal.

- Rollers shape fins with exact sizes.

- Operators can set the machine for different fin types.

Here is a table that shows how precision helps:

| Feature | Result |

|---|---|

| Exact thickness | Better heat transfer |

| Same spacing | Stronger radiators |

| Smooth edges | Easy assembly |

Precision means less waste and fewer problems when putting things together.

Cost Efficiency

Factories want to save money. Radiator fin machines help by using less material and energy. The machines cut each fin to the right size, so there is little scrap. Automation means fewer workers are needed. This lowers labor costs.

- Machines use only the metal needed for each fin.

- Less waste means more savings.

- Fewer mistakes mean less fixing.

DAG’s machines let companies switch fin types without changing rollers a lot. This saves time and money.

Companies that use cost-efficient machines can give better prices to customers.

Flexibility

Radiator fin machines give factories many choices. They help companies change what they make. Workers can switch fin sizes and materials easily. This makes the machines good for lots of jobs.

- Operators test fins with different widths and thicknesses. They use the same machine for aluminum or copper. This saves both time and money.

- The machines have digital screens. Operators see menus on touch screens. They change settings fast and watch the process.

- Quality control features help workers check each fin. The machine tests fins before they leave the line. This keeps products working well.

- Precision tools measure each fin. They make sure every piece is made right. This helps companies give strong and efficient radiators.

- The machines work well even when things get busy. They keep running under tough conditions.

DAG’s radiator fin machines let users change settings quickly. Operators pick the fin type, size, and material on the screen. The machine changes rollers and feeding speed. This means one machine can make straight, wavy, or louvered fins. Companies do not need new machines for every job.

Tip: Quick changes help factories fill orders for many customers. They switch products fast without waiting long.

Here is a table that shows how flexibility helps:

| Feature | Benefit |

|---|---|

| Adjustable fin sizes | Meets different needs |

| Material compatibility | Uses aluminum or copper |

| Fast setup changes | Saves time |

| Quality control tools | Keeps products reliable |

| Durable design | Handles busy work |

Factories face new problems often. Customers want custom radiators or special fin shapes. DAG’s machines help companies react fast. Operators change settings and start a new batch. The machine keeps everything smooth.

Workers do not need special training to use these machines. The touch screen shows each step. They see alerts if something is wrong. This makes the job easier and safer.

Radiator fin machines help companies grow. Businesses add new products without buying more equipment. They keep costs low and meet market needs. Flexibility helps businesses stay ahead in a busy industry.

Radiator Fin Machine Applications

Automotive

Radiator fin machines are important in making cars. Car companies use these machines to make fins for radiators, condensers, and intercoolers. Every car needs a cooling system that works well. The machines help make fins in many shapes and sizes. This lets engineers design cooling systems for cars, trucks, and buses.

Car factories often need to change fin types. Some cars need straight fins. Others use wavy or louvered fins. Radiator fin machines make switching easy. Operators change settings on the screen. The machine then makes the right fin for each car. This helps car makers follow rules for engine heat and emissions.

A finned tube radiator keeps the engine cool. The fins move heat away from the coolant. This keeps the engine at the right temperature. When the radiator works well, the car lasts longer and uses less gas. Radiator fin machines help car makers build cars that drivers can trust.

HVAC

HVAC systems use many kinds of fins. Radiator fin machines make these fins fast and with good accuracy. HVAC companies use copper or aluminum fins. These metals move heat well. The machines can make wavy, straight, or porous fins for different jobs.

Porous wavy fins give more surface area for heat. This helps HVAC systems cool or heat air better. When the fin gets cold, water in the air turns to drops. This is called dehumidification. It releases heat and helps cooling. Copper fins are best for this because they move heat fast. The right fin shape also helps air move through the system.

Radiator fin machines let HVAC makers change fin shape and spacing. This means they can make systems for homes, offices, or factories. The machines help save energy and lower costs. They also help HVAC systems last longer by keeping parts cool. A good finned tube heat sink keeps equipment working well for years.

Note: Good fin design in HVAC systems saves energy, lowers bills, and makes things work better.

Power Generation

Power plants and transformer stations need strong cooling. Radiator fin machines help by making fins for transformers and other gear. The machines make fins that move heat away from electric parts. This keeps transformers cool and safe.

Here are some main benefits of using radiator fin machines in power plants:

- They help move heat away, so transformers last longer.

- Fast machines make more fins and need fewer workers.

- Digital controls keep fin quality the same.

- Good use of materials means less waste and saves money.

- Careful design makes sure each fin fits right.

- Factories can make many fin shapes for different transformers.

- Machines can handle big orders and work in tough places.

- Using materials well is better for the environment.

A good radiator in a power plant keeps things from getting too hot. This helps stop breakdowns and power loss. Radiator fin machines help power companies build safe and strong systems.

Electronics

Electronics need good cooling to work well. Computers, servers, and power supplies get hot when used. Radiator fin machines help by making fins for heat sinks and radiators. These fins pull heat away from important parts.

A finned tube radiator in a computer moves heat from coolant to air. The fins give more surface area. This helps heat leave the device faster. Fans blow air over the fins. The air takes the heat away. This keeps electronics cool and safe.

Many electronics use liquid cooling. Coolant flows through tubes and touches the fins. The fins move heat from the coolant to the air. Radiator fin machines make fins with exact shapes and sizes. This helps the cooling system work better.

A finned tube heat sink sits on top of chips like CPUs and GPUs. The fins spread heat out. Air moves over the fins and carries heat away. Radiator fin machines make different fin shapes for each device. Some fins are straight. Others are folded or bonded. Each type helps with different cooling needs.

Electronics makers use radiator fin machines for many jobs. They build cooling systems for computers, power electronics, and control panels. The machines let them pick the right fin type for each job. This keeps devices at the right temperature and helps them last longer.

Tip: Good cooling helps electronics work faster and stay safe.

| Device Type | Cooling Solution | Role of Radiator Fin Machine |

|---|---|---|

| CPU/GPU | Finned tube heat sink | Makes fins for heat dissipation |

| Power Supply | Finned tube radiator | Produces fins for liquid cooling |

| Control Panel | Custom heat sink fins | Shapes fins for airflow |

Radiator fin machines help electronics companies solve new problems. They make fins for many devices and cooling systems. This keeps electronics safe and helps them work better every day.

Applications of Fin Press Machines

Heat Exchangers

A fin press shapes the metal fins that go inside heat exchange equipment. These fins help move heat from one place to another. Many factories use a fin press to make these fins because the process is fast and accurate. Here is how a fin press helps in making heat exchangers:

- The fin press stamps or cuts thin metal sheets, often aluminum or copper, into special fin patterns.

- The machine feeds the metal, cuts it, forms it, and stacks the fins.

- These fins go into heat exchangers, where they help transfer heat.

- The fin press works at high speed and makes thousands of fins every hour.

- Each fin comes out the same size and shape, which helps the heat exchanger work well.

- The fin press can make many types of fins, like flat, wavy, or offset.

- The machine uses metal well and does not waste much.

- Many industries, such as HVAC and automotive, use a fin press for this job.

- The fin press gives better results than other ways of making fins because it is fast and makes every fin the same.

A fin press helps companies build heat exchangers that last and work well.

Condensers

A fin press also plays a big part in making condensers. These machines use high-speed punching and smart controls to shape fins quickly. The fin press uses automated systems to feed the metal and punch out fins. This keeps the process fast and the fins the right size. The machine has safety features and easy controls. Workers can change the mold fast if they need a new fin shape. The fin press can make many types of condenser fins, which helps factories meet different needs. This makes the production of condensers steady and reliable. The fin press helps keep costs low and quality high.

Tip: A fin press with good controls and safety features helps workers do their jobs better and keeps the factory running smoothly.

Transformer Radiators

Transformer radiators need strong and steady cooling. A fin press makes the fins that go into these radiators. The machine shapes each fin so it fits well and moves heat away from the transformer. The fin press can handle both aluminum and copper. It makes sure every fin is the right size. This helps the radiator keep the transformer cool. A fin press can switch between different fin shapes if needed. This helps companies make radiators for many types of transformers. The machine works fast, so factories can fill big orders without delay.

Here is a table that shows how a fin press helps in different jobs:

| Application | What the Fin Press Does | Why It Matters |

|---|---|---|

| Heat Exchangers | Makes many fins fast | Better heat transfer |

| Condensers | Shapes fins with accuracy | Reliable cooling |

| Transformer Radiators | Forms strong, steady fins | Keeps transformers safe |

The applications of fin press machines cover many industries. Each fin press helps companies make products that last and work well. The fin press gives factories the speed, accuracy, and flexibility they need to stay ahead.

Choosing the Right Machine

Production Volume

Factories must decide how many fins they need daily. Some places make only a few fins at a time. Others need thousands every hour. The best radiator fin machine matches how much you want to make. Fast machines work well for busy factories. These machines can go up to 280 meters each minute. They help companies finish big orders quickly.

Operators pick machines with automatic feeding and stacking. These features keep everything moving. When machines run fast, workers do not wait long. DAG has machines for small and big jobs. Companies choose the model that fits their work. Busy factories save time and money with high-volume machines.

Tip: Companies should look at their order sizes first. Picking the right machine keeps work smooth and stops slowdowns.

Material Compatibility

Radiator fin machines use different metals. Aluminum and copper are the most popular. Each metal has good points and some problems. Aluminum radiators are light. They help cars use less gas. Copper-brass radiators move heat fast. They work well in trucks and older cars.

Material compatibility changes how long radiators last. Aluminum does not rust but needs the right coolant. Copper-brass radiators are easy to fix but might leak. Some machines use special coatings to stop rust. Factories in tough places pick machines with strong tanks and mounts.

Here is a table that compares aluminum and copper-brass radiators:

| Aspect | Aluminum Radiators | Copper-Brass Radiators |

|---|---|---|

| Weight | Lightweight, improves fuel efficiency and handling | Heavier, can negatively impact performance |

| Corrosion Resistance | High, corrosion-resistant but sensitive to coolant compatibility | More prone to rust and corrosion |

| Repairability | Difficult to repair, often requires welding | Easily repairable via soldering |

| Heat Transfer | Efficient due to design (larger tubes, thinner fins) | Superior thermal conductivity but heavier |

| Durability | Resistant to leaks due to fewer soldered joints | More soldered joints increase leak risk |

| Cost | Higher initial cost but lower maintenance over time | Lower initial cost but higher maintenance and repair |

| Suitability | Modern vehicles, harsh environments, lightweight needs | Classic cars, frequent repairs, heavy-duty trucks |

Operators pick machines that work with their chosen metal. DAG’s machines handle both aluminum and copper. This lets companies switch jobs without buying new machines.

Customization

Factories sometimes need special fin shapes or sizes. Customization helps companies meet customer needs. Radiator fin machines give many choices. Operators can change fin thickness, width, and type. Machines use rollers to make straight, wavy, or louvered fins.

DAG’s machines have PLC control, inverter speed, and touch screens. These tools help workers set up new jobs fast. Companies can pick machines for aluminum or copper fins. Fast and automatic models help with big orders.

Here is a table that shows some customization choices:

| Customization Aspect | Details |

|---|---|

| Fin Types | Straight, serrated, perforated, wavy, louvered, and others |

| Fin Thickness | 0.07 – 0.08 mm (minimum for wavy fin) |

| Fin Width | 8 – 200 mm |

| Materials | Aluminum and copper |

| Machine Features | PLC control, inverter speed adjustment, servo feeding, touch screen operation |

| Machine Variants | Aluminum fin-forming, copper fin-forming, high-speed, ultra-fast, automatic fin-collecting |

| Fin-Forming Roller | Changeable to produce different fin models on the same machine |

| Application | Automotive radiators, air conditioning, industrial heat exchangers |

Operators also change tube types, core densities, and mounting brackets. Some machines add logos or sensors. Special coatings help with hard jobs. DAG helps with custom requests and setting up machines for new products.

Note: Customization helps factories stay ready for new market needs.

Support Services

Support services are very important when picking a radiator fin machine. Many companies want more than just the machine. They also want help before and after buying it. Good support helps factories keep working and fix problems quickly.

A good support team helps in many ways:

- Installation Help: Factories often need help to set up new machines. Support teams show workers how to install them. This makes sure everything works from the start.

- Training: Workers must learn how to use the machine. Support teams teach them how to run, clean, and fix it. Good training helps workers make fewer mistakes.

- Technical Support: Machines can stop or have errors sometimes. Support teams answer questions and fix problems fast. Quick help means less time waiting.

- Spare Parts Supply: Machines need new parts after some time. A good supplier keeps spare parts ready. This helps factories fix machines without waiting long.

- Consulting Services: Some companies want to make their process better. Support teams give advice on using the machine well. They help with new products or special jobs.

Tip: Companies with strong support help customers work better and save money.

DAG is known for great support services. Their technical team helps with installation at the factory. They answer questions and fix problems quickly. DAG also gives free consulting. This helps customers solve issues and improve their process. Many people trust DAG because help is always nearby.

A table shows which support services matter most:

| Service Type | Why It Matters |

|---|---|

| Installation Help | Gets machines running fast |

| Training | Reduces mistakes |

| Technical Support | Fixes problems quickly |

| Spare Parts Supply | Keeps machines working |

| Consulting | Improves production |

Support services help companies use their machines well. They also help factories grow and handle new problems. When choosing a radiator fin machine, many companies pick brands like DAG for strong support and expert help.

Radiator fin machines let factories make things faster and with fewer errors. They use new tech like 5mm fin spacing and wide fin pitch. This helps cooling work better and saves money. Companies get better quality and waste less material. Many pick these machines because they work with new materials. They also fit changing needs. As the radiator industry gets bigger, choosing the right machine helps businesses grow. It keeps them ready for new ideas and bigger markets.

FAQ

What does a radiator fin machine do?

A radiator fin machine makes metal fins for radiators and other coolers. It uses rollers and smart controls to shape each fin. Every fin comes out the right size and shape.

Which materials can DAG’s machines handle?

DAG’s machines work with aluminum and copper. Operators choose the metal for each job. Both metals move heat well and last a long time.

How fast can a radiator fin machine produce fins?

Some machines make fins at 280 meters per minute. This helps factories finish big orders fast. Production keeps moving without long waits.

Can one machine make different fin types?

Yes! DAG’s machines make straight, wavy, and louvered fins. Operators use the touch screen to change settings. The machine changes rollers and speed by itself.

Do operators need special training?

No. DAG’s machines have touch screens and easy menus. Workers learn quickly with help from DAG’s team. Training helps keep mistakes low.

What support does DAG offer?

DAG gives help with setup, training, and spare parts. Their team answers questions and fixes problems. Free consulting helps customers work better.

Where do companies use radiator fin machines?

Factories use these machines in cars, HVAC, power plants, and electronics. Each place needs fins for cooling and heat exchangers.

How does automation help production?

Automation keeps the work steady and fast. Machines cut and stack fins the right way. This saves time, lowers mistakes, and cuts waste.