A core builder machine puts together aluminum radiator and condenser cores. It does this by placing tubes, fins, header plates, and side plates together. DAG makes machines that line up tubes and fins very well. This helps the radiator work better and makes the product higher quality. Companies use these machines to build faster and get the same results each time. Automation and computer controls help the machines work quicker and need less workers. The machines work well and have checks to make sure things are done right. This helps companies make more products and save money.

Key Takeaways

- Core builder machines put together radiator and condenser cores fast and right, which makes the products better.

- These machines use automation to make fewer mistakes, work faster, and save money on workers.

- DAG has manual, semi-automatic, and fully automatic machines for different factory sizes and needs.

- The machines use exact mechanical, pneumatic, and electrical systems to put parts in the right place and keep people safe.

- Factories can pick options to make different core sizes and types, so they can handle new needs.

- Doing regular maintenance and training workers helps the machines work well and stops expensive problems.

- DAG gives strong customer support with setup, training, spare parts, and help any time of day.

- Picking the best machine depends on how much you make, your budget, if it fits your needs, and your plans to grow.

Overview

What It Is

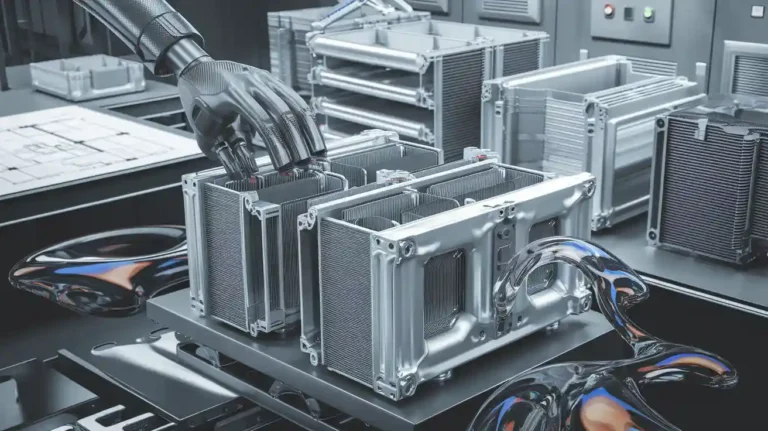

A core builder machine helps factories put together the main parts of aluminum radiators and condensers. The machine puts tubes, fins, header plates, and side plates in the right order. Many companies use these machines to build their products. The machine uses moving arms, air-powered parts, and electric controls to place each piece. Workers can set the machine for different sizes and shapes.

DAG has a Radiator Core Builder Machine that uses new technology. It can put together radiator cores, condensers, and intercoolers. The machine works with 2-row, 4-row, and 5-row models. It also has types with PLC and servo controls. These features help the machine work with many radiator cores.

Note: The DAG Radiator Core Builder Machine can handle big core sizes and different fin widths. This makes it good for many car products.

Main Purpose

The main job of a core builder machine is to make building radiator and condenser cores faster and more exact. Factories use these machines to make their products better. The machine puts each tube and fin in the right place. This helps the radiator or condenser work well in a car or truck.

In the car industry, heat exchangers like radiators and condensers need strong and even cores. The core builder machine helps companies reach this goal. It cuts down on mistakes and keeps each product the same. This saves time and money.

DAG’s machine also lets companies change what they make quickly. They can switch between different core sizes and types fast. This helps both big and small jobs.

Tip: Using a core builder machine can help a factory meet high standards for quality and speed in making car heat exchangers.

How It Works

Assembly Process

Tube and Fin Placement

The assembly starts with checking all the parts. Workers or machines look at tubes, fins, header plates, and side plates to make sure they are good. Jigs hold each part so everything stays straight. Sensors watch for mistakes or problems. The machine puts tubes and fins in the right order. It lines up header plates with the tubes and fins. The system pushes the parts together to make the radiator core. The machine checks the space between fins and tubes to match the plan. This step gets the core ready for the next part, like brazing.

- Check all parts before putting them together.

- Put tubes and fins in the right order.

- Line up header plates with tubes and fins.

- Push parts together to make the core.

- Check spaces to make sure they are correct.

- Get the core ready for brazing.

- Move the core to the next step.

Note: Sensors and PLC systems help control how fast and hard the machine presses. This keeps the work correct and the same every time.

Core Stacking

Core stacking means adding layers to the radiator or condenser. The machine puts tubes and fins on top of each other. Jigs and guides help keep each layer straight. The system checks where every part is. If something is wrong, sensors tell the operator. The machine presses the stack so all parts fit tightly. This step helps the core stay strong when used.

Automation

Automation is very important in new assembly lines. Machines do the same jobs quickly and correctly. Automated inspection finds problems early. The machine follows set instructions for each step. This lowers mistakes and keeps quality high. Automation also saves money on workers and makes things safer by doing risky jobs.

- Machines work faster and never get tired.

- Automated systems follow set instructions.

- Robots and sensors find problems right away.

- Automation makes work faster and more products.

- Workers can do more important jobs.

Tip: Automation helps the core builder machine make more radiator and condenser cores in less time.

Manual vs. Automatic

Manual and automatic core builder machines work differently. The manual machines use hand tools or simple parts. Workers must put each piece in place. This way is good for small jobs. It needs more workers and takes longer. The quality can change from one product to another.

Automatic machines use hydraulic or electric controls. They can make lots of products. These machines need less help from people. They keep the size and quality the same for every core. Automatic machines work faster and waste less material. They cost more at first but save money later.

| Aspect | Manual Core Builder Machines | Automatic Core Builder Machines |

|---|---|---|

| Operation | Hand tools or simple parts | Fully automated with hydraulic/electric controls |

| Production Scale | Good for small jobs | Good for big jobs |

| Labor Requirement | Needs more workers | Needs fewer workers |

| Initial Cost | Costs less at first | Costs more at first |

| Output Quality | Quality can change | Quality stays the same |

| Efficiency | Slower and less efficient | Faster and more efficient |

| Material Wastage | Wastes more material | Wastes less material |

| Operational Costs | Costs more for workers over time | Costs less for workers, uses more energy |

| Technical Expertise | Needs little skill | Needs skilled workers and maintenance |

| Infrastructure | Needs little space and few facilities | Needs more space, steady power, regular maintenance |

Modern automatic machines control every step very closely. This makes them more accurate and repeatable. Factories get better products and more of them. Automation also lowers mistakes and keeps costs down over time.

Features

Key Components

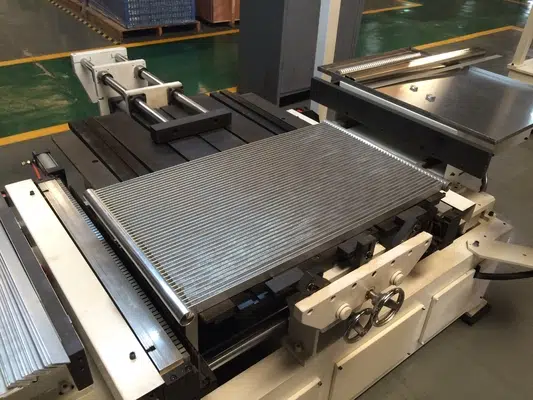

Mechanical Systems

A core builder machine has many moving parts. The frame and table keep everything steady. Pressing adjustment mechanisms set the right pressure for each part. Comb mechanisms help guide fins and tubes into place. Tube distribution and laying mechanisms move tubes to the right spot. Header molds and side plate positioning blocks keep plates straight. Core clamping mechanisms hold the core tight while it is built. Slide rails and guide rails help parts move smoothly. Precision aluminum profiles make the machine strong and stable.

- Frame and work table

- Pressing adjustment mechanisms

- Comb mechanisms

- Tube distribution and laying mechanisms

- Header molds and side plate positioning blocks

- Core clamping mechanisms

- Slide rails and guide rails

- Precision aluminum profiles

All these mechanical systems work together. They help each part fit well and stay in the right place.

Pneumatic and Electrical Controls

Pneumatic systems use air cylinders to move parts. These systems control how parts press together and move during assembly. Pneumatic controls work with mechanical and servo systems for better accuracy.

Electrical controls use PLC systems and touch screens. PLC means Programmable Logic Controller. It helps the machine follow instructions. Servo motors move parts quickly and exactly. Electrical control systems from brands like Mitsubishi, Schneider, LG, Omron, and IFM make the machine reliable. Photoelectric safety devices help keep workers safe. Servo drives control speed and movement.

- Pneumatic cylinders and controls

- PLC control systems

- Touch screens

- Servo motors and drives

- Electrical control systems from trusted brands

- Photoelectric safety devices

These controls help the machine work fast, safe, and with high accuracy.

Customization Options

DAG lets companies change the core builder machine in many ways. Companies can pick OEM and ODM services for special needs. The machine can build different radiator, condenser, and intercooler cores. Maximum assembly sizes can change for different products. The machine can only build cores with one fin height at a time. Companies can order machines for different fin heights. Radiator and condenser cores need separate machines because their pipes are not the same.

| Customization Aspect | Details |

|---|---|

| Fin Shape and Size | Machines can make different fin shapes and sizes for each customer. |

| Hob Usage | One hob makes fins of one height; companies can change hobs as needed. |

| Fin Width | One hob can combine up to 10 different fin widths. |

| Machine Types | Manual, semi-automatic, and fully automatic machines are available. |

| Programmed Assembly | Automatic machines can be programmed for different core specifications. |

| Radiator vs Condenser Cores | Separate machines are needed for each core type. |

This flexibility helps companies meet many needs and switch between products easily.

DAG’s core builder machine can build 2-row, 4-row, and 5-row cores. The PLC and servo motor controls help put tubes and fins in the right place. This makes assembly more accurate and brazing better. DAG machines also make less noise and are easy to use.

Assembly Accuracy, Noise Levels, and Supported Core Sizes

DAG’s machine keeps assembly accurate and quiet. The PLC and servo controls help line up parts within ±2°. The sound power level is 109 dB(A), and the sound pressure level is 93 dB(A). Vibration at the hand wheel is less than 2.5 m/s². The machine supports core bit diameters from 12 mm to 300 mm without extra parts, and up to 500 mm with spacers. These features help companies build many types of radiator and condenser cores.

| Parameter | Value/Range | Notes |

|---|---|---|

| Sound power level (L WA) | 109 dB(A) | Uncertainty ±3 dB(A) |

| Sound pressure level (L pA) | 93 dB(A) | Uncertainty ±3 dB(A) |

| Vibration at hand wheel | ≤ 2.5 m/s² | Measured per EN 62841-3-6 |

| Supported core bit diameter | 12 mm to 300 mm | Without accessories |

| Supported core bit diameter | 12 mm to 500 mm | With spacers |

| Angular accuracy for alignment | ±2° | For leveling and drill stand alignment |

DAG’s machine gives strong technical support and is easy to use. Companies can change fin heights, core sizes, and assembly speeds to fit their needs. This makes the machine a good choice for many radiator and condenser production lines.

Core Builder Machine Benefits

Efficiency

A core builder machine helps factories finish work faster. Workers do not spend as much time on each core. The machine puts tubes, fins, and plates in place quickly. Automated systems move parts without stopping for breaks. Sensors watch every step and warn workers if there is a problem. This helps stop delays and keeps things moving. Companies can make more products in less time. The machine also makes fewer mistakes, so less fixing is needed. Fast machines help factories finish big orders on time.

Tip: Automated material handling systems make work faster and safer. Workers can do other jobs while the machine lifts heavy parts.

Quality

Factories want radiator and condenser cores that always work well. The core builder machine lines up tubes and fins very carefully. Computer controls make sure each part goes in the right spot. Servo motors and PLC systems help keep everything tight and even. This makes strong cores that last longer in cars and trucks. Good quality means fewer returns and happier customers. The machine checks for mistakes and keeps every product the same. Companies can trust the machine to make each batch just as good as the last.

| Quality Feature | Benefit |

|---|---|

| Precise tube placement | Stronger core structure |

| Even fin distribution | Better heat transfer |

| Automated error checks | Fewer defects |

| Consistent assembly | Reliable product performance |

Cost Savings

Factories save money by using a core builder machine. Automated systems need fewer workers, so labor costs are lower. The machine uses materials better, so there is less waste. Fewer mistakes mean less money spent fixing or replacing parts. Fast work helps companies fill orders quickly and avoid waiting. The machine uses energy wisely, so bills are lower. Maintenance is easy, so the machine does not stop for long. Companies can change core sizes and types without buying new machines. This helps save money for both small and big jobs.

Note: Computer control and robotics make setup faster and stop long breaks. Factories can use their resources better and change plans quickly when needed.

Flexibility

Manufacturers want machines that can work with many products. DAG’s radiator core builder machine gives users lots of choices. Operators can change the machine to build radiator cores, condenser cores, or intercooler cores. This helps companies handle new orders and market changes.

The machine can build cores in many sizes. Operators can set it for cores up to 1800 mm long, 1200 mm wide, and 56 mm thick. The fin width can be from 8 mm to 200 mm. So, one machine can make small heater cores or big truck radiators. Companies do not need to buy a new machine for every product.

DAG lets users customize the machine for special needs. Operators can pick different assembly speeds, fin heights, and core setups. The machine can switch between 2-row, 4-row, and 5-row models. Operators use the touch screen and PLC controls to change settings. This makes starting new jobs easy and cuts down on waiting.

Tip: Flexible machines help factories make small batches or big orders. Operators can change settings fast and keep working.

The machine also offers OEM and ODM services. DAG works with customers to design machines for special products. Companies can ask for special features or sizes. This helps manufacturers stay ahead and meet customer needs.

A flexible machine helps companies save money. Operators can use one machine for many jobs. This means less equipment and lower costs. The machine’s design lets operators switch jobs quickly. They can move from one product to another without long stops.

| Flexibility Feature | Benefit |

|---|---|

| Adjustable core size | Builds many types of radiator and condenser cores |

| Programmable controls | Quick setup for new jobs |

| Multi-row support | Handles different core configurations |

| Customization options | Meets special production needs |

| Fast changeover | Reduces downtime and increases output |

Operators say the machine is easy to use. The touch screen shows clear steps. PLC controls help set up new jobs with simple instructions. This makes training easier and helps new workers learn fast.

Flexible machines help companies grow. When demand changes, operators can adjust the machine for new products. This keeps production busy and helps companies get more business.

Note: DAG’s support team helps customers set up machines for new products. They give free advice and help any time to fix problems quickly.

A flexible core builder machine gives manufacturers what they need. Operators can build many types of cores, switch jobs, and keep production running well.

Core Builder Machine Types

Manual

Manual core builder machines use simple tools and basic parts. Operators do every step by hand. They put in tubes, fins, and plates one at a time. These machines are good for small shops or places with low needs. Manual machines cost less to buy and fix. They use little power and are easy to take care of. Operators must pay close attention because mistakes can happen fast. Manual machines are not good for big orders. They work best for custom jobs or when only a few cores are needed.

Semi-Automatic

Semi-automatic machines mix hand work with some machine help. Operators load the parts and start the job. The machine does some steps, like pressing or stacking. This makes work faster and cuts down on mistakes. Semi-automatic machines are good for medium-sized factories. They cost more than manual ones but less than full automatic. Operators still need to watch and make changes if needed. These machines can handle different core sizes and types. They let workers switch jobs quickly. DAG’s semi-automatic models have PLC controls and touch screens. This makes them easy to set up and use.

Fully Automatic

Fully automatic machines do almost all the work by themselves. They load, line up, press, and stack parts with smart controls. Operators just watch the system and do upkeep. Fully automatic machines are best for big factories with lots of work. They cost the most but are the fastest and most exact. These machines need fewer workers and keep quality the same. DAG’s fully automatic models use PLC systems, servo motors, and touch screens. They can change jobs fast and make lots of cores. DAG also gives on-site setup, training, and 24/7 help to keep things running well.

Note: DAG sells all three types of machines. The company has manual, semi-automatic, and fully automatic models. Each one fits different needs, from small jobs to big factories.

Comparison Table

| Aspect | Manual Machines | Semi-Automatic Machines | Fully Automatic Machines |

|---|---|---|---|

| Operation | Operators do all steps | Some steps automated, operator input needed | Almost all steps automated, minimal labor |

| Efficiency | Low | Moderate | High |

| Initial Cost | Lowest ($100–$3,000) | Moderate ($700–$5,000) | Highest ($20,000–$200,000) |

| Labor Requirement | High | Moderate | Low |

| Maintenance | Simple | Moderate | Needs skilled technicians |

| Operational Cost | Low | Moderate | Higher |

| Scalability | Low | Medium | High |

DAG’s machines work with many fin types and sizes. Operators can use the same machine for straight, wavy, or louvered fins. The machines work with both aluminum and copper. DAG also helps with advice, setup, and custom options. This helps companies pick the best machine for their needs.

Selection Guide

Production Needs

Manufacturers need to think about what they make. They should know how many radiator or condenser cores they build each day. Some factories make only a few. Others make hundreds every day. The best machine matches what the factory wants to do. Fast machines help big factories fill large orders. Small shops may pick slower machines for special jobs.

Operators should see if the machine works with aluminum and other metals. This lets the factory make different products. Automation features like CNC controls and PLC systems make work quicker and more exact. Machines that are easy to fix and have spare parts keep work going. Factories should also plan for the future. Machines that can upgrade or add new tech help protect their money.

| Consideration | Explanation |

|---|---|

| Compatibility with metals | Machine must be good for aluminum and other metals to handle products right. |

| Production capacity | Capacity should match how much is made to keep work fast and quality high. |

| Technological features | Automation and CNC features make work more exact and save on workers. |

| Dependability and maintenance | Easy fixing and spare parts help the machine last and work more. |

| Support and spare parts | Good support and parts mean less downtime and steady work. |

| Adaptability to future tech | Upgrading or adding new tech keeps the machine useful for a long time. |

| Customization and integration | Machine should fit with other systems to keep work smooth and avoid problems. |

Tip: Factories should choose a machine that fits their daily needs and can grow with their business.

Compatibility

Compatibility means the machine fits with what the factory already has. Operators need to check if the machine works with their current systems. The machine should handle the sizes and shapes they want to build. Some machines work with many fin types, tube sizes, and plate shapes. This helps factories switch between products quickly.

Factories should see how the machine connects to other equipment. Machines with standard controls and interfaces are easier to set up. Operators should check if the machine uses the same power and safety systems. Machines that fit well with other tools help work go smoothly and fast.

Note: Picking a machine that matches the factory’s needs helps stop problems and keeps work steady.

Budget

Budget is important when picking a machine. Manual machines cost less and are good for small jobs. Semi-automatic machines cost more and help with medium orders. Fully automatic machines cost the most and are best for big factories.

Operators should look at all costs, not just the price to buy. Fixing, spare parts, and upgrades add to the cost over time. Machines with good support and easy repairs save money later. The table below shows usual budget ranges for different machine types:

| Machine Type | Duty Level | Typical Budget Range (USD) |

|---|---|---|

| Manual | Light Duty | $10,000 – $25,000 |

| Manual | Medium Duty | $20,000 – $40,000 |

| Semi-Automatic | Medium Duty | $30,000 – $55,000 |

| Fully Automatic | Heavy Duty | $50,000 – $100,000 |

Operators should pick a machine that fits their budget and does what they need. Spending more on a good machine can save money later.

Tip: Factories should plan for future costs like upgrades and spare parts when making their budget.

Support

Support is very important when picking a machine for making radiators and condensers. Companies need more than just the machine itself. They also need help to keep things working well. Good support lets workers fix problems quickly and avoid long stops.

DAG gives strong support to its customers. The company gives free advice before you buy a machine. This helps buyers choose the best machine for their work. After buying, DAG sends experts to help set up the machine. These experts show workers how to use it and run it for the first time. This hands-on help makes sure the machine works right from the start.

Training is a big part of support. DAG teaches workers and repair staff how to use the machine. They learn to change settings and fix small problems. Training helps workers feel sure about their jobs and make fewer mistakes. Well-trained workers can keep the machine running longer and safer.

Spare parts and repair services help keep machines working well. DAG keeps common parts ready in stock. Customers can get new parts fast if something breaks or wears out. Getting parts quickly means the machine does not stop for long. DAG also checks machines often to find and fix small problems early.

Customer service is always open, day and night. If something goes wrong, workers can call or message for help. DAG’s team answers questions and gives easy steps to fix problems. This quick help stops long delays in the factory. The company also helps online. Workers can get help with software or fixing problems without waiting for a visit.

A good support system gives:

- Free advice before buying

- Help with setup at your factory

- Training for workers and repair staff

- Fast delivery of spare parts

- Regular machine checkups

- 24/7 customer service

- Online help and updates

Tip: Companies should ask about support before buying a machine. Good support saves time and money while using the equipment.

The right support helps companies keep making products without stopping. It also helps them change to new products or meet new needs. DAG’s support helps customers get the best use from their machine.

Operation and Maintenance

Best Practices

Operators should follow some important steps to keep machines working well.

- Plan regular maintenance and always follow the schedule.

- Teach all workers how to use and care for the machine.

- Use tools that show problems as they happen.

- Set the same machine settings for each job.

- Have short meetings every day to talk about how the machine is working.

- Use information to find and fix what causes stops.

- Give everyone a clear job so they know what to do.

When operators do these things, machines stop less often and work stays steady. Training and talking clearly help the team do better.

Maintenance Tips

Checking machines every day, week, and month helps them last longer.

- Daily: Look for damage, check oil and fluids, clean off dust, test safety stops, and listen for strange sounds.

- Weekly: Adjust the machine, clean or change filters, add more oil, test sensors and controls, and check logs for problems that happen again.

- Monthly: Look for cracks or worn parts, check all wires, adjust belts and gears, test the machine with different loads, and update repair records.

Taking care of the machine often helps find problems early. This keeps the machine safe and working well. Good records help plan repairs and stop surprises.

Regular checks help stop breakdowns and keep the machine working smoothly.

Troubleshooting

Operators sometimes see common problems. Fixing them fast keeps work going.

Alignment

If parts do not line up, check for loose bolts or worn guides. Adjust guides and clamps. Make sure the table is flat. If it still does not work, look for bent parts or things blocking movement.

Feeding Issues

If tubes or fins do not feed right, look for jams or worn feeders. Clean the feeding path. Change old parts. Check sensors for dust or damage. Make sure settings match the size of the material.

Control Errors

If the machine is slow or stops, check all wires for damage. Make sure the power is steady. Look in the control box for water or dust. Reset the PLC if needed. If it still does not work, call a trained technician.

| Issue | What to Check | Solution |

|---|---|---|

| Hydraulic problems | Oil quality, leaks | Use good oil, fix leaks |

| Overheating | Lubrication, airflow | Change oil, clean radiators |

| Electronic control failures | Wiring, power, moisture | Fix wires, dry control box |

| Operator mistakes | Training, logs | Train staff, keep records |

DAG gives help all day and night and can come to your site. Their team helps set up, trains workers, and answers questions fast. Operators can get help any time, so machines keep running and stop less often.

Manufacturers know that using advanced machines helps make radiators and condensers better. DAG gives good machines that can be changed or made automatic. When picking a machine, they should think about how much work is done by machines, how much room they have, what sizes they need, and how much money they can spend.

- The amount of automation should fit how much is made.

- How much space and what sizes are needed matter.

- Custom options help with special needs.

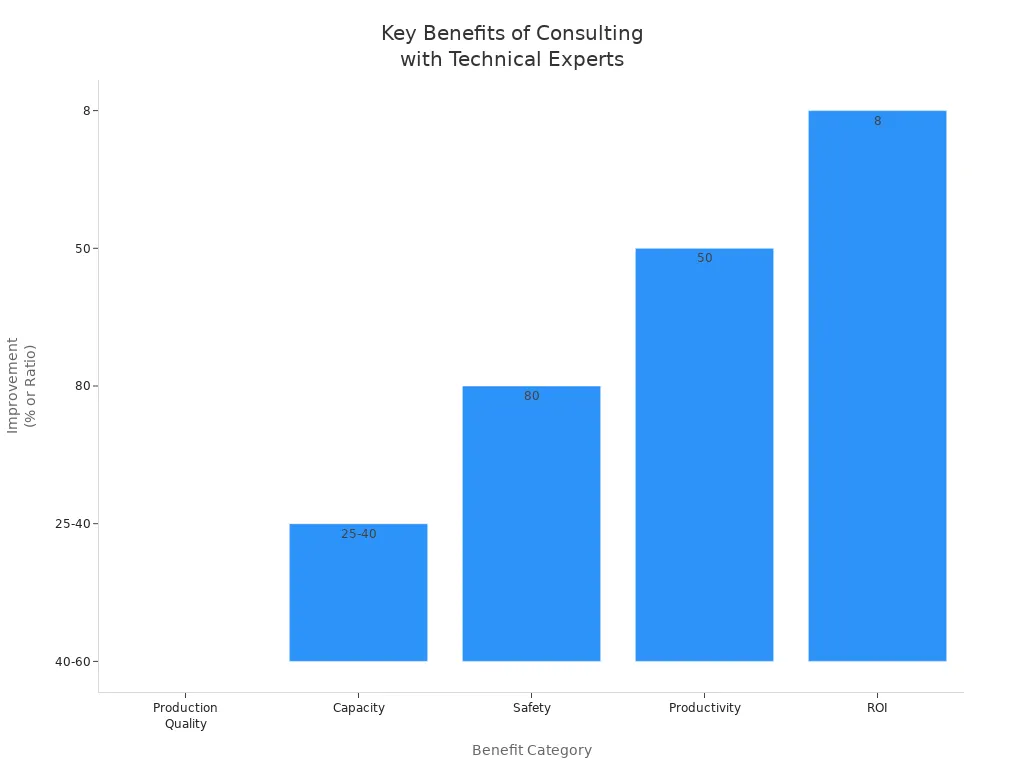

Talking to experts makes the work better, safer, and faster. Experts help factories make more products and have fewer mistakes. The table below shows how expert advice helps.

| Benefit Category | Specific Benefits from Consulting with Technical Experts |

|---|---|

| Production Quality | Improved production quality, decreased defects by 40-60% |

| Capacity | Capacity increases between 25-40% |

| Safety | Reduction in safety incidents up to 80% |

| Productivity | Productivity increase up to 50% |

| Return on Investment (ROI) | Average ROI of 8:1 |

Seeing a machine in action helps buyers understand what it can do. Demos help people trust the company and see how the machine works. Buyers can ask questions and learn about quality and how well the machine works. Manufacturers can contact DAG for help or to see a demo before buying.

FAQ

What does a core builder machine do?

A core builder machine puts tubes, fins, header plates, and side plates together. It makes radiator or condenser cores for cars and trucks. The machine helps factories build these parts fast and with good accuracy.

Can one machine build different core sizes?

Yes. DAG’s machine can make many core sizes. Operators can set it for cores up to 1800 mm long, 1200 mm wide, and 56 mm thick. This gives factories more choices for what they build.

How does automation help in core building?

Automation lets the machine work faster and make fewer mistakes. Sensors and computer controls check each step as the machine works. This helps factories make more products in less time.

What materials can the DAG machine assemble?

The DAG Radiator Core Builder Machine works with aluminum and copper. It can build radiator, condenser, and intercooler cores for many kinds of vehicles.

How often should operators maintain the machine?

Operators should check the machine every day for dust, oil, and damage. Weekly and monthly checks help keep the machine safe and working well. Regular care stops breakdowns before they happen.

Does DAG offer training and support?

Yes. DAG gives free advice, on-site setup, and worker training. The company also has 24/7 customer service and sends spare parts quickly.

Can the machine be customized for special needs?

DAG offers OEM and ODM services for special requests. Customers can ask for different features, sizes, or assembly speeds. This helps factories meet their own production needs.

What should operators do if the machine stops working?

Operators should look for loose parts, jams, or control errors. If the problem does not go away, they can call DAG’s support team for fast help.