Choosing the right radiator core builder machine means checking what your factory needs. You should look at machine features, automation, compatibility, cost, and support. Each factory must pick a machine that matches its radiator production goals. The best machine will fit the factory size, the types of radiator products, and how much automation is needed. DAG gives machines that help factories make radiator cores very accurately. Factory managers should pick machines that work for both current and future radiator lines.

Key Takeaways

- Pick a radiator core builder machine that matches your factory size. Think about your production goals and the types of products you make.

- Find machines with lots of automation. This helps work go faster, lowers mistakes, and keeps workers safer.

- Choose a machine that works with many radiator core sizes. It should also handle different fin types and materials. This gives you more options.

- Look for machines that can grow with your factory. This helps if your factory gets bigger or changes in the future.

- Check if the machine has good precision features. This makes sure you get high-quality radiator cores and less waste.

- Pick machines that use less energy. This saves money and helps the environment.

- Make sure the new machine fits well with your other equipment. It should also work with your factory’s layout.

- Choose suppliers who give good after-sales help. They should have spare parts and offer training for your workers.

Radiator Core Builder Machine Basics

What Is a Radiator Core Builder Machine

DAG is a top company in radiator making machines. They are known for making good machines for radiator factories. A radiator core builder machine is used to put together radiator parts. It connects header plates, side plates, fins, and flat tubes. These parts form the main body of the radiator. The machine uses different systems to place each part right. Workers use touch screens and PLC controls to run it. The machine is not very loud and works quickly. Factories use it to make sure every radiator core is built well. This helps the radiator look good and work right in the next steps.

The main jobs of a radiator core builder machine are:

- Putting together header plates, side plates, fins, and flat tubes.

- Making sure each part is in the right spot.

- Helping the assembly stay steady and fast.

- Letting factories make different radiator sizes and types.

- Being easy to use and not noisy.

- Making radiator cores that help the radiator work well.

Role in Radiator Production

The radiator making machine is very important in the factory. It is the main machine for putting the core together. This step is key for how well the radiator works. The machine makes sure each core meets high quality rules. Good core assembly means better heat exchange and longer life. The machine helps factories make many radiators fast. It uses smart controls to lower mistakes and speed up work. This step matters because a strong core helps the radiator work in cars and machines. Factories trust this machine to give the same good results every time.

Types and Technologies

There are different kinds of radiator making machines. Factories can pick manual, semi-automatic, or fully automatic ones. Each kind gives a different amount of help and speed. More factories now want automatic machines for better work. Some still use manual machines, but automatic ones are faster and more flexible.

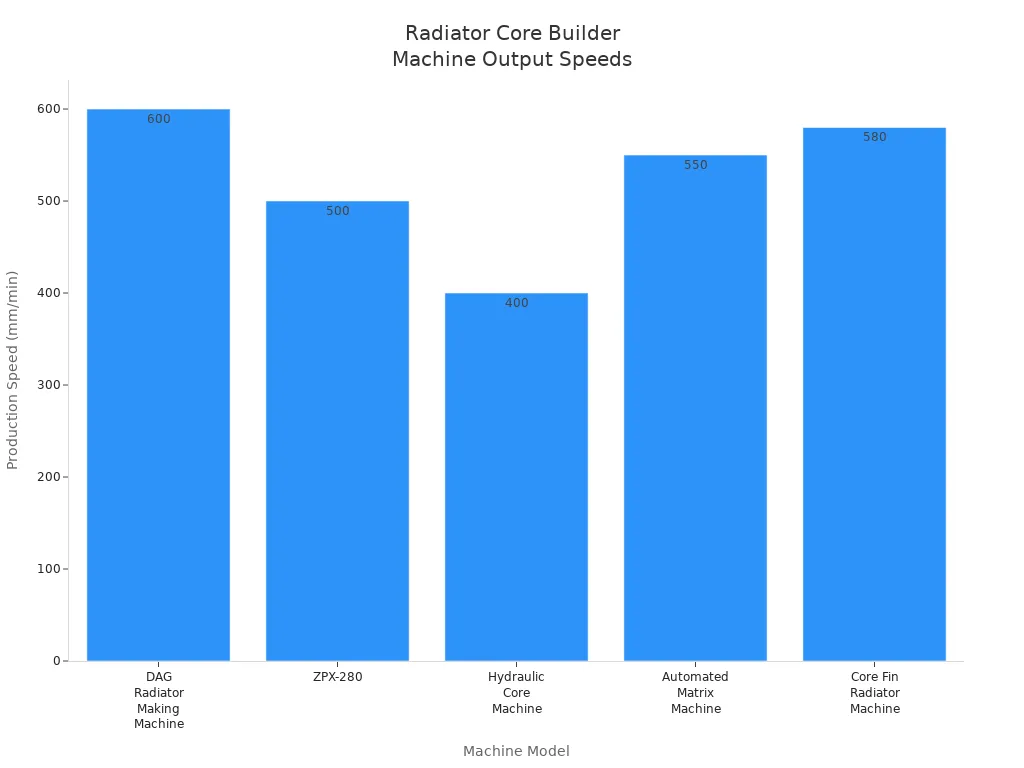

| Machine Model | Automation Level | Production Speed (mm/min) | Supported Core Sizes (mm) | Material Compatibility | Customization Options |

|---|---|---|---|---|---|

| DAG Radiator Making Machine | Full | Up to 600 | 150 – 800 | Aluminum, Copper | Yes |

| ZPX-280 | Semi/Full | Up to 500 | 120 – 700 | Aluminum | Yes |

| Hydraulic Core Machine | Semi | Up to 400 | 100 – 600 | Aluminum, Brass | Limited |

| Automated Matrix Machine | Full | Up to 550 | 130 – 750 | Aluminum | Yes |

| Core Fin Radiator Machine | Full | Up to 580 | 140 – 780 | Aluminum, Copper | Yes |

DAG’s machine uses full automation, PLC controls, and servo motors. This makes it fast and able to work with many sizes and metals. Other machines, like the Hydraulic Core Machine, are semi-automatic and use different metals. Factories choose a machine based on how many radiators they need and what kind. Automation cuts down on mistakes and hard work. Custom options let factories make special radiator shapes. More factories want advanced machines as the need grows in cars and HVAC.

Assessing Production Needs

Output and Volume

Each factory must know how many radiators it needs daily. The machine should match this number. Some factories make hundreds each day. Others make thousands. Faster machines with more automation help with big orders. Managers need to check how fast the machine works. They should see how many radiator cores it can build in an hour. This helps stop delays and keeps the factory working well.

Tip: Always get ready for busy times. Pick a machine that can handle your busiest days without slowing down.

If a factory wants to grow, it should pick a machine that can do more. This stops slowdowns and helps the factory get bigger. The right machine keeps work steady and helps meet deadlines.

Product Range

Factories make many kinds of radiators. These include tube and fin, plate and fin, downflow, and crossflow. Each kind is used for different jobs in cars or machines. The machine must work with all sizes and materials, like aluminum or copper. Some cars need special radiators made from all aluminum. These need machines with special features.

A machine that can build many designs gives the factory more choices. Some machines are best for simple tube-and-fin radiators. Others can make harder plate-and-fin or brazed aluminum cores. If the machine can switch between types, it saves time. This helps the factory meet what customers want and keep up with changes.

Radiator cores come in many shapes and sizes. The machine must work with these changes and still be fast and correct. A machine that can handle many sizes and materials helps the factory make more products. This makes the factory work better and gives higher quality radiators.

Scalability

Factories often get bigger over time. Managers should think about what the factory will need later. A scalable machine can make more radiators or new types as the factory grows. Some machines let you add more automation or new controls. This means the factory does not need to buy a new machine soon.

A machine with parts you can change or easy software updates helps the factory grow. The factory can add new things or make the machine faster when needed. This saves money and keeps the factory up to date. Scalability makes sure the machine is still good as the factory changes.

Note: Buying a scalable machine helps the factory if demand or products change.

A smart choice now means fewer problems later. The right machine grows with the factory and helps new business.

Key Features to Consider

Precision and Quality

Precision and quality are very important for these machines. Factories need machines that build radiator cores very accurately. The right machine puts each part in the correct spot. This helps the radiator work well in real life.

The table below shows key precision and quality facts for a radiator core builder machine:

| Metric | Value/Description |

|---|---|

| Number of indenters | 3 |

| Running speed | Adjustable |

| Air pressure requirement | 0.8 Mpa |

| Maximum size of head plate | 100 mm |

| Maximum core size | 800 x 800 x 100 mm |

| Frequency | 50 Hz |

| Number of cylinders | 6-8 |

| Voltage | 220 V |

| Efficiency (core build time) | About 4-5 minutes per core |

| Built-in precision system | Yes, ensures accurate assembly |

| Construction | Durable, supports long service life |

These facts help the machine make good radiator cores every time. The speed can change, and the air pressure stays steady. This keeps the quality high, even if the factory makes more or less. The machine can build different sizes of radiator cores. The built-in precision system makes sure each core is made right. This helps the radiator last longer and work better.

Tip: Good assembly every time means less waste and a better name for the factory.

Automation Level

Automation changes how factories build radiator cores. A machine with high automation can put tubes and fins in place with little help. This means fewer mistakes and faster work. Factories with automated machines can make more radiators and fill big orders.

Automated machines use sensors and smart controls to check each step. These features help the machine stay accurate. Workers do not have to do as much by hand. They can focus on checking quality. Automation also makes the work area safer and lowers the chance of getting hurt.

Some machines let you pick manual or automatic modes. This gives the factory more ways to work. Managers can choose what works best for each job. As the factory grows, it can use more automation to meet new needs.

Control Systems

Control systems are like the brain of the radiator core builder machine. Most machines use a PLC to run the controls and screens. The PLC works with touch screens, so the machine is easy to use. Servo motors help the PLC move parts very exactly.

This setup makes the machine work well and stay steady. The machine puts flat tubes in the right place and spreads fins evenly. These things help the radiator core get built right and make brazing better. The control system also keeps noise down and makes the machine simple to use.

A strong control system lets the machine work with many radiator types. Factories can switch products fast without losing time. The machine keeps working well, even if the factory changes what it makes.

Energy Efficiency

Energy efficiency is very important when picking a radiator core builder machine. If a factory uses an energy-efficient machine, it can save money. This kind of machine does not use as much electricity each time it works. Using less energy means there is less waste and it is better for the planet.

Many factories want machines with smart control systems now. These systems make sure the machine only runs when it needs to. For example, a smart start-stop feature keeps the machine off when not working. This helps the factory save money over time.

A radiator core builder machine with energy-saving motors and pneumatic systems helps too. These motors use less power but still keep the machine fast. Pneumatic systems use air to move parts. They only use energy when moving, not when stopped.

Tip: Factories should look at the energy rating before buying a machine. A high rating means the machine uses less power for each radiator it makes.

The table below shows how energy efficiency helps factories:

| Feature | Impact on Factory |

|---|---|

| Energy-saving motors | Lower electricity bills |

| Smart control systems | Less wasted energy |

| Pneumatic tube distribution | Efficient part movement |

| Idle mode or auto shut-off | No power loss when idle |

A factory with an energy-efficient machine can make more radiators with the same power. This helps the business grow and keeps costs low. Energy efficiency also helps the factory be more eco-friendly. Many customers like products from factories that care about the earth.

A radiator core builder machine with good energy-saving features gives the factory a big advantage. It helps the factory reach its goals and stay ahead of others.

Compatibility and Integration

Existing Equipment

Factories use many radiator making machines in one line. When a new machine is added, it must work with the old ones. The new machine should connect easily to other machines. It needs to use common ways to talk to other equipment. This helps all machines work together.

Workers and repair staff must learn how to use the new machine. Training helps everyone know how to run and fix it. All teams should plan together before adding the machine. The factory must check if the power and speed match the other machines. Good machines are easy to fix and do not break often.

Tip: Always look at your current machines and plan with your team before you add a new radiator making machine.

- Main problems when adding a new machine:

- Making sure it works with the old machines

- Teaching workers how to use it

- Planning with every team

- Checking power, speed, and size

- Picking machines that are easy to fix

Factory Layout

Where you put the machine matters a lot. Managers should put the radiator making machine near other machines. There should be enough space for people and parts to move. The machine should be close to others to keep work moving fast.

A good setup helps the machine work with many fin types and materials. The machine needs space for loading and unloading radiator cores. Clear walkways help move things without waiting. The factory should also think about adding more machines later or changing what they make.

Note: A smart layout keeps workers safe and helps the line run without stopping.

Radiator Core Specifications

Every radiator has its own core size, fin type, and material. The machine must work with these needs. Some machines can build many core sizes and fin shapes. Others only work with certain materials like aluminum or copper.

Managers should see if the machine can make the radiator cores they need. The machine should switch fast between different core sizes and fin types. This helps the factory give customers what they want and try new designs.

A machine that works with many radiator core types gives the factory more choices. It also helps the factory keep up with new market changes.

Tip: Pick a machine that fits the radiator core sizes, fin types, and materials your factory uses most.

Maintenance and Support

After-Sales Service

Good after-sales service keeps the factory working. When a factory buys a radiator core builder machine, it needs help from the supplier. The supplier should answer questions fast and help with problems. Many suppliers give support by phone or online. Some send workers to the factory for setup or repairs. This help lets the factory fix issues quickly. Fast help means less waiting and more work done. Good service also helps the factory trust the supplier.

Spare Parts

Spare parts are very important for the factory’s success. If a machine breaks, the factory needs new parts fast. Getting spare parts quickly helps fix the machine without long stops. This keeps the radiator line on time. Easy spare parts also save money on repairs. The factory does not have to wait long to fix things. Over time, this help keeps the machine working well and stops big repair costs. Factories should pick suppliers who keep spare parts ready and ship them fast.

Training

Training teaches workers to use the radiator core builder machine safely. When a new machine comes, the supplier often gives training. Workers learn how to set up, use, and take care of the machine. Good training shows how to check, clean, and fix simple problems. This helps workers find and fix issues early. Well-trained workers keep the line running well. Training also helps new workers learn faster. Suppliers who give clear books and hands-on lessons help factories a lot.

Tip: Training often helps workers learn new features and best ways to work.

Budget and Investment

Cost vs. Value

Factory managers need to think about both price and value. The cost changes with how much automation the machine has. Bigger machines usually cost more money. For example, a semi-automatic radiator core builder machine costs about $60,000. If the factory wants more automation or special parts, the price goes up. Some machines for other heat exchange equipment are much cheaper. But those machines cannot make as many radiator cores or do the job as well.

| Machine Type | Price (USD) | Automation Level | Capacity/Specs |

|---|---|---|---|

| Semi-automatic Radiator Core Builder Machine | 60,000 | Semi-automatic | Max core size 800x800x100mm, 1 workstation, 3 indenters, 4-5 min/core |

| Other heat exchange equipment | 600 – 9,999 | N/A | Lower capacity, different equipment types |

A machine with more automation can build radiator cores faster. This saves the factory money on workers and cuts down on mistakes. Managers should also think about how the machine helps in the long run. A good machine with easy-to-find spare parts and support costs less to fix. It also keeps the factory running without stopping.

Tip: The best machine is one that fits the factory’s needs and works well for a long time.

Financing

Manufacturers give different ways to pay for a radiator making machine. Most suppliers take L/C or T/T payments. Usually, factories pay half the money first and the rest before delivery. Factories can talk to suppliers to get a better price. It takes about 30 days for the machine to arrive. The machine comes packed safely in wooden boxes.

- Common payment options:

- L/C (Letter of Credit)

- T/T (Telegraphic Transfer)

- Typical payment terms:

- 50% down payment

- 50% before delivery

- Delivery time: About 30 days

- Secure packaging: Wooden cases

These payment rules help factories plan their spending. Most suppliers do not give loans or credit, so factories need to pay before the machine ships.

Comparing Brands

Picking the right radiator making machine is about more than just price. DAG sells machines straight from the factory, so prices are lower. They let factories add their own brand or special features. DAG gives free samples, technical help, and promises to deliver on time.

| Feature | DAG Radiator Core Builder Machines | Other Leading Brands |

|---|---|---|

| Pricing | Competitive, factory direct | Not always direct |

| Customization Options | OEM/ODM, branding, special features | Varies by brand |

| Automation & Precision | Advanced, fast, high precision | Good, but details differ |

| Technical Support | 24/7, free samples, training | Good, but may not offer samples |

| Delivery & Quality Guarantee | On-time, 100% qualified | Varies |

| Adaptability | Works with many core sizes and materials | Usually flexible |

DAG’s machine is easy to change and comes with strong support. Other brands may have similar machines, but DAG lets factories choose more options and get better value.

Note: Managers should look at features, support, and long-term value before picking a radiator making machine.

Safety and Compliance

Safety Features

Factory managers need to keep workers safe. New radiator core builder machines have special safety systems. These systems help stop accidents and make the work area safer.

- Photoelectric light curtains use sensors to watch the work zone. If someone steps in, the machine stops right away.

- Two-hand push buttons make the worker use both hands to start the machine. This keeps hands away from moving parts and stops mistakes.

These safety systems help everyone stay safe at work. Managers should check for these features before buying any radiator machine.

Certifications

Certifications show that a radiator core builder machine is safe and high quality. These approvals help factories sell in more places and gain trust. The table below lists the most important certifications for radiator machines:

| Certification | Purpose/Proof | Impact on Market Access |

|---|---|---|

| ISO 9001 | Shows a strong quality management system and consistent performance | Builds trust and supports sales in many countries |

| CE | Confirms compliance with European safety and health standards | Allows legal sales and safe operation in Europe |

| Other Local Certifications | Meets country-specific legal and market requirements | Enables legal sales and operation in local markets |

These certifications help factories follow rules and reach more buyers. Machines with these approvals show the maker cares about safety and quality. When picking a radiator core builder machine, managers should always ask to see these certifications.

Picking the right radiator core builder machine takes some thought. Factory managers need to look at what their factory needs now and later. They should check the machine’s features and support. The checklist in this guide can help compare machines. Talking to trusted companies like DAG is a good idea. This makes sure the machine is right for the factory. Managers should think about their needs and ask experts before buying.

FAQ

What types of radiator cores can DAG’s machine assemble?

DAG’s machine can build many radiator core types. It works with different sizes and fin shapes. The machine uses materials like aluminum and copper. It can make tube-and-fin, plate-and-fin, and multi-row designs.

How long does installation and training take?

Most setups finish in just a few days. DAG’s team comes to help and teach workers. Workers learn how to use and care for the machine fast.

Can the machine integrate with existing production lines?

Yes, it can. DAG makes machines that fit with other equipment. The machine connects easily and fits most factory layouts.

What maintenance does the machine require?

The machine needs regular cleaning and checks. Workers should look at moving parts and change worn pieces. DAG gives spare parts and helps with repairs.

Does DAG offer customization for special radiator designs?

DAG offers OEM and ODM services for factories. The team can change machines for special core sizes or fin types.

What safety features come with the machine?

The machine has photoelectric light curtains and two-hand push buttons. These features help keep workers safe and stop accidents.

How does DAG support customers after purchase?

DAG gives 24/7 technical support and quick spare parts. The company helps fix problems and gives free advice.

What certifications do DAG radiator core builder machines have?

DAG machines have ISO 9001 and CE certifications. These show the machines are safe and high quality.