DAG Radiator Header Plate stands out in 2025 by using advanced aluminum alloys that provide excellent cooling performance and can be customized to fit various needs. Choosing the right radiator header plate is essential for vehicles handling heat and heavy-duty work. Studies show that quality radiator header plates protect engines and improve their efficiency. Tests confirm that the radiator header plate prevents breaks at tube joints, helping engines avoid overheating. As a trusted radiator header plate supplier, DAG ensures vehicles stay safe and perform reliably today.

Key Takeaways

- DAG Radiator Header Plate uses three special aluminum alloys. These alloys help control heat and last a long time.

- DAG makes custom sizes for a tight fit. This stops leaks and works with many radiator types.

- The anodized finish on DAG plates keeps out rust and damage. This makes the plates last longer.

- DAG gives extra help like machines, training, and fast spare parts. This helps both factories and users.

- Picking the right header plate means you check fit, material, thickness, and if it resists rust.

- Good steps during installation stop leaks. They also keep the engine cool and safe.

- Spending more on good plates like DAG saves money later. You will have fewer repairs and lose less coolant.

- Other brands like Mishimoto, Denso, and Spectra Premium are simpler or cheaper. But they do not have as many features.

Comparison Table

Key Specs

The table below lists the main specs for four top radiator header plates in 2025. Each brand uses its own materials and designs. These choices change how well the plates work in cars.

| Brand | Material (Main Alloy) | Thickness (mm) | Fitment Options | Corrosion Resistance | Heat Dissipation | Price Range ($) | Standout Winner |

|---|---|---|---|---|---|---|---|

| DAG | 4343/3003/7072 Aluminum | 1.5 (custom) | Customizable | Excellent | Superior | 45-70 | 🏆 Yes |

| Mishimoto | 3003 Aluminum | 1.2-1.5 | Standard | Good | High | 40-65 | |

| Denso | 3003 Aluminum | 1.2 | OEM Fit | Good | Moderate | 38-60 | |

| Spectra Premium | 3003 Aluminum | 1.2 | Standard | Moderate | Moderate | 35-55 |

DAG is special because it uses several aluminum alloys, lets you pick the size, and has great corrosion resistance. The table shows DAG gives the best mix of strength, fit, and lasting power.

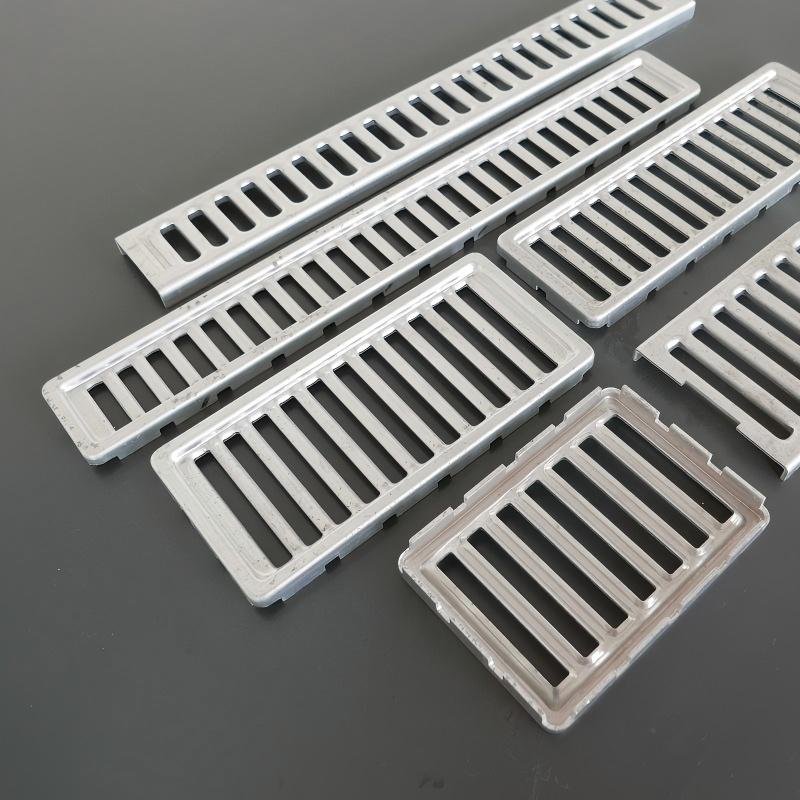

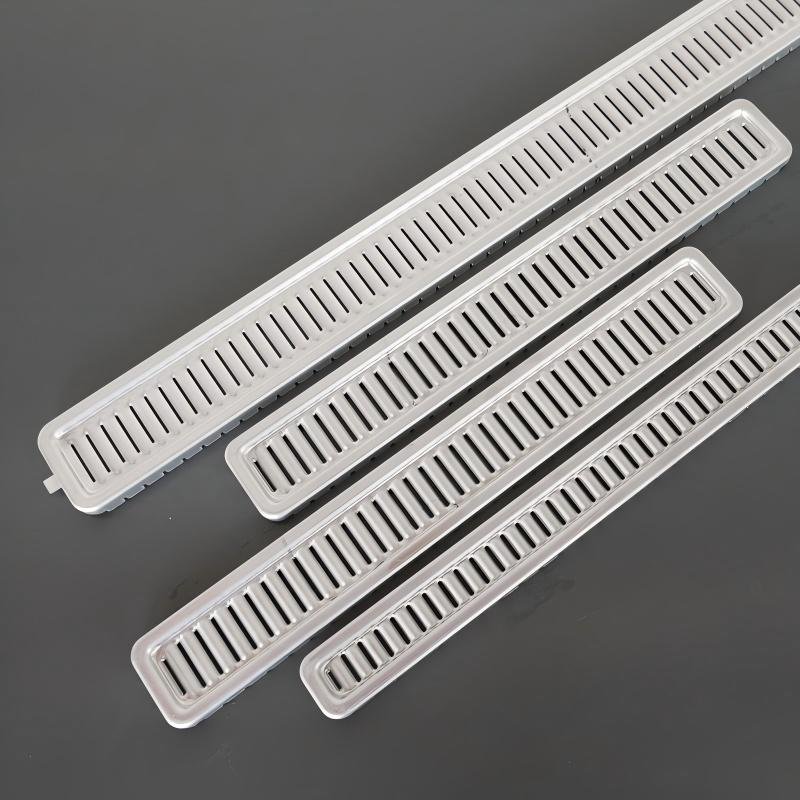

Standout Features

- DAG uses a blend of 4343, 3003, and 7072 aluminum alloys. This blend helps the radiator header plate handle heat and last longer. The plates come in different sizes and thicknesses. DAG adds an anodized layer to stop rust and damage.

- Mishimoto uses 3003 aluminum. Their header plates fit most regular radiators. They move heat well and are simple to put in.

- Denso makes plates for OEM fit. Their header plates use 3003 aluminum and work best as factory replacements. They have average heat dissipation.

- Spectra Premium sells header plates at lower prices. They use 3003 aluminum and fit many cars. Their corrosion resistance is not as high as others.

Lab tests show polymeric hollow fiber radiator header plates can reach up to 93% thermal efficiency. Aluminum radiators, like DAG’s, can reach up to 84%. Polymeric plates are best at moving heat, but DAG’s aluminum header plates still work well and are reliable for most cars.

DAG’s header plates also help radiator factories by giving extra machines and quick customer service. This help makes sure users get the right fit and good performance.

Why It Stands Out

Material and Build

DAG uses three types of aluminum alloys in its radiator header plate. Each alloy has a special job. The 7072 alloy is strong and can handle high heat, even up to 150°C. The 4343 alloy helps the plate move heat fast and stops rust. The 3003 alloy makes it easy to shape the plate. When these alloys are mixed, the plate becomes tough and steady. The anodized layer gives extra protection. This helps the plate last longer and not wear out fast.

- 7072 alloy stays strong in hot places.

- 4343 alloy moves heat fast and stops rust.

- 3003 alloy is easy to shape for many designs.

- Anodized finish keeps the plate safe and strong.

DAG lets you pick the size you need for your header plate. This means the plate fits tightly in the engine bay. A tight fit stops leaks and keeps air from getting out. Custom sizes also fit many radiator types, like crossflow or downflow. This makes the plate work well in lots of vehicles.

Performance

DAG’s radiator header plate works well in hot and tough places. The strong alloys stop the plate from bending or breaking. The plate’s shape helps move heat away from the engine. This keeps the engine cool and safe. Good radiators work better with this plate.

Custom sizes help the plate fit better. A good fit means no leaks and better cooling. The plate can fit many radiator cores, like multi-row or thick-core aluminum radiators. This makes it a smart pick for cars and trucks.

DAG helps radiator factories too. The company gives machines and tools for easy setup and making plates. They also give training, advice, and send spare parts fast.

Note: DAG’s team helps set up machines, trains workers, and fixes problems fast. This makes it easy to install and saves time.

Durability

DAG makes its header plates to last a long time. The strong alloys and anodized layer stop rust and damage. The plate keeps its shape and strength for years. Custom sizes help the plate fit well, so it does not get damaged easily.

| Support Option | Description |

|---|---|

| Installation Guidance | On-site help for setting up machines |

| Training Programs | Hands-on lessons for workers and technicians |

| Technical Consulting | Expert advice for better operations |

| Spare Parts Supply | Fast delivery of replacement parts |

| Upgrade Options | New features and machine updates available |

DAG gives a warranty for parts, labor, and help. The company fixes problems fast. This helps radiator factories grow and keep working well.

Radiator Header Plate Reviews

DAG Radiator Header Plate

Pros and Cons

- Uses three aluminum alloys for strength and heat control.

- You can pick the size and thickness you need.

- The anodized surface helps stop rust and damage.

- It is easy to install because holes and TABs are even.

- Works well in hot places, up to 150°C.

- DAG gives extra help to factories, like machines and training.

- It costs more than some other choices.

Best For

DAG Radiator Header Plate works for many things. It is good for car radiators, oil coolers, and air conditioning parts. Factories use it for both normal and special radiator designs. The plate fits many core sizes, from small cars to big trucks. Big factories and small shops both like its flexibility and easy setup. Experts say DAG’s header plate is great for people who need strong cooling in big trucks and tough vehicles.

Mishimoto Radiator Header Plate

Pros and Cons

- Made from 3003 aluminum, which is used a lot.

- Fits many cars with its standard size.

- Moves heat away well.

- Most people can install it easily.

- It costs less than some custom plates.

- You cannot change it much for special radiators.

- It might not fit all thick or multi-row radiators.

Best For

Mishimoto Radiator Header Plate is good for daily cars and light trucks. It is best for people who want a simple part to replace. Many car owners pick Mishimoto because it fits well and works in most cars. It may not work for custom cars or ones that need special cooling.

Denso Radiator Header Plate

Pros and Cons

- Uses 3003 aluminum for okay strength and heat transfer.

- Made to fit just like the factory part.

- Good for replacing old factory plates.

- Stops rust a little but not as much as others.

- Not the best for custom or high-performance cars.

- Does not have many choices for multi-row radiators.

Best For

Denso Radiator Header Plate is for people who want a part just like the original. It works well in regular cars and light trucks. Denso’s plate is good for people who want to keep their car close to how it was made. It may not be right for people who want special features or sizes.

Spectra Premium Radiator Header Plate

Pros and Cons

Spectra Premium makes radiator header plates from 3003 aluminum alloy. This alloy keeps the plate strong but not heavy. Many people pick Spectra Premium because the plates fit lots of cars. The company makes these plates for normal radiator swaps. Most plates are 1.2 mm thick, which works for most daily cars.

Pros:

- Affordable Price: Spectra Premium header plates cost less than most brands. This helps people who want to save money.

- Wide Compatibility: The plates fit many car models. Mechanics use them for fast swaps.

- Lightweight Design: The 3003 aluminum alloy keeps the plate light. This makes it easy to handle when putting it in.

- Simple Installation: The holes and tabs match most factory radiators. This makes repairs faster.

- Availability: Many auto parts stores sell Spectra Premium. Drivers can find new plates quickly.

Cons:

- Moderate Corrosion Resistance: The 3003 aluminum alloy does not stop rust as well as some alloys. People who drive on salty roads may see more rust over time.

- Standard Thickness Only: Spectra Premium usually has just one thickness. This means fewer choices for custom or special cars.

- Average Heat Dissipation: The plate moves heat away, but not as well as thicker or special alloy plates.

- Limited Trend Features: Spectra Premium does not have dark finishes or multi-row use as standard. Some people may want these new features.

Note: Spectra Premium header plates are best for normal cars. They may not work for high-performance or custom radiator systems.

Best For

Spectra Premium radiator header plates are good for drivers who want a cheap and reliable fix. Mechanics use these plates for daily cars and older vehicles. Fleet managers pick them for cars and trucks that need regular care. The simple design fits most factory radiators, so repairs are quick and easy.

Spectra Premium plates are not for high-performance cars. They work best in cars that do not get very hot or carry heavy loads. Owners of sedans, small cars, and light trucks get the most from these plates. The standard thickness and fit help keep costs down.

Fleet operators and repair shops like how easy it is to get Spectra Premium parts. The brand’s wide reach means cars spend less time waiting for repairs. Drivers who need a fast fix for a leaking radiator often choose Spectra Premium.

Tip: If you want new styles, like dark finishes or multi-row use, other brands may have more choices. Spectra Premium is best for value and everyday use.

Choosing the Right Radiator Header Plate

Compatibility

Picking the right radiator header plate means checking if it fits. Every car is different and needs a certain plate. The plate must match the car’s model and engine. Mechanics look at the car’s make, model, and year first. They also check the radiator’s size and weight. If the plate fits well, it stops leaks and is easier to put in.

- Always see if the plate fits your car.

- Make sure the radiator cools enough for your car.

- Aluminum plates move heat well and are lighter.

- Check if the plate fits the engine right.

- OEM or real parts work best and last longer.

- The radiator should be made for your car by the maker.

- Aluminum cores that fight rust last longer.

- Look at the size and weight before buying.

A good fit keeps leaks away and makes fixing easier. Mechanics like OEM parts because they fit just right. When the plate fits well, it keeps coolant in and stops leaks at the joints.

Budget

How much you spend matters when picking a radiator header plate. Some people want the cheapest one, but others want one that lasts. Plates made with better aluminum cost more but last longer and stop leaks. Cheaper plates might save money now but can cause more repairs later.

Drivers should look at prices and think about all costs. Spending more on a good plate means fewer repairs and less coolant to buy. Mechanics say it’s smart to get a plate that stops leaks and keeps the system working. This saves money on repairs and coolant over time.

Features to Consider

Some things make a radiator header plate better. The material is very important. Aluminum alloys move heat well and don’t rust easily. How thick the plate is changes how strong it is and how it fits. Plates that come in different thicknesses fit more radiators.

Other good things are:

- Anodized finishes help stop rust.

- Holes that are spaced out make it easy to put in.

- Custom sizes fit special radiator shapes.

- Some plates work with multi-row radiators for better cooling.

- Dark finishes look cool and some people like them.

Mechanics like plates that make leaks easy to find. Plates with clear marks or bright surfaces help spot leaks fast. This makes repairs quicker and keeps coolant from leaking out. Picking a plate with these things helps stop leaks, makes repairs faster, and keeps the system safe.

Tip: Always look for plates that help you find and fix leaks. A good plate keeps coolant in and stops leaks that cost a lot to fix.

Installation Tips

Installing a radiator header plate requires careful steps. A good installation helps the radiator work well and keeps the engine safe. Many people can do this job with basic tools and some patience. These tips help users avoid mistakes and get the best results.

- Prepare the Work Area

Start by parking the vehicle on a flat surface. Let the engine cool down before starting. Hot parts can cause burns. Gather all needed tools, such as wrenches, screwdrivers, and safety gloves. - Drain the Coolant

Place a drain pan under the radiator. Open the drain valve and let the coolant flow out. This step prevents spills and keeps the work area clean. Save the coolant if it is still good, or plan to use new coolant after the repair. - Remove the Old Header Plate

Disconnect any hoses or wires attached to the radiator. Remove the bolts or clips holding the old header plate. Lift the plate off carefully. Check for any signs of a leak or damage. If you see a leak, clean the area before moving on. - Clean the Surface

Use a clean cloth to wipe the radiator core and the area where the new plate will sit. Remove any dirt, old gasket material, or debris. A clean surface helps the new plate seal well and prevents leaks. - Install the New Header Plate

Place the new header plate onto the radiator core. Make sure the holes line up with the tabs and mounting points. Use the correct bolts or clips to secure the plate. Tighten them evenly to avoid bending the plate. - Check for Proper Fit

Inspect the installation. The plate should sit flat with no gaps. A tight fit helps stop leaks and keeps the radiator strong. If the plate does not fit, do not force it. Check the size and shape again. - Reconnect Hoses and Wires

Attach all hoses and wires back to their places. Make sure each connection is tight. Loose hoses can cause leaks or make the radiator work poorly. - Refill the Coolant

Pour coolant back into the radiator. Use a funnel to avoid spills. Fill to the recommended level. Start the engine and let it run for a few minutes. Watch for leaks around the new header plate. - Inspect and Test

After the engine warms up, turn it off and check the area again. Look for any signs of a leak. If you find one, tighten the bolts or check the fit. If everything looks good, the repair is complete.

Tip: Always use the right type of coolant for your vehicle. Check the owner’s manual if you are not sure. A good repair keeps the radiator working well and helps the engine stay cool.

Regular checks after installation help spot leaks early. Quick action can prevent bigger problems and save money on future repair jobs.

DAG Radiator Header Plate is the top pick in 2025. It uses strong aluminum alloys and can be made in different sizes. This makes it work well for many people. The comparison and reviews help readers find what they need. If you want to learn more, you can check out technical blogs, videos, and guides.

- Research & Development pages

- Coil Selection Software

- Technical blogs

- Videos and Webinars

- Infographics and Guides

DAG is a good choice for drivers and radiator experts.

FAQ

What is a radiator header plate?

A radiator header plate links the radiator tubes to the tank. It keeps coolant inside so it does not leak out. The plate also helps hold the radiator together. It moves heat away from the engine to keep it cool.

Why does material choice matter for header plates?

The material changes how strong the plate is. It also affects how well it moves heat and fights rust. Aluminum alloys like 4343, 3003, and 7072 make the plate last longer. These alloys help the plate work well in hot engines.

How do I know if a header plate fits my vehicle?

First, check your car’s make, model, and year. Measure the size of your radiator. Then look at the product’s details and compare them. Plates that can be changed, like DAG’s, fit many radiator types.

Can I install a radiator header plate myself?

Most people can put in a header plate with simple tools. Follow the steps in the guide to help you. Always check for leaks after you finish. If you are not sure, ask a mechanic for help.

What makes DAG’s header plate different?

DAG uses three aluminum alloys for extra strength and heat control. The company lets you pick custom sizes and adds an anodized finish. These things help the plate last longer and fit more cars.

How often should I check my radiator header plate?

Look at your radiator and header plate every few months. Check for leaks, rust, or any damage. Checking early helps stop big problems and keeps your engine safe.

Do dark finishes or multi-row compatibility matter?

Dark finishes can look nice and hide dirt better. Multi-row compatibility means the plate fits thicker radiators. These features help with cooling and style for some cars.

Where can I buy a DAG radiator header plate?

You can buy DAG radiator header plates from official dealers or the website. Contact DAG’s customer service if you need help or have questions.