Product Introduction

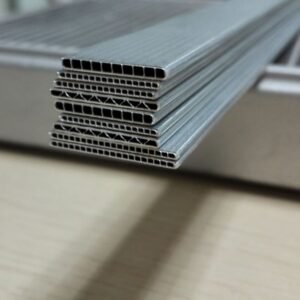

Aluminum Alloy Flat Tube For Automotive Radiator / Charge Air Cooler

Material: Aluminum Alloy 4343/3003/7072; 4343/3005/7072; 4343/3003; 4343/3003/4343; 4045/3003; 4045/3003/7072; 3003

Aluminum tubes are available in a wide range of sizes and alloys to ensure optimum performance for the required application.

Tubes are primarily clad in aluminum, enabling the combination of low melting point brazing alloys with high strength cores and the addition of corrosion resistant inner cladding as required. New high-strength, corrosion-resistant, long-life alloys are now in regular production, offering the possibility of cost and weight reductions.

Cores with brazing alloys on both the inner and outer surfaces can be used in pressurized air and oil cooler applications, allowing internal spoilers to be brazed to the tube wall, creating an uninterrupted heat flow medium from coolant to air.

High frequency welded aluminum alloy flat tube for automobile radiator

| Tube size(mm) | Wall thickness(mm) |

| 16 * 1.5 | 0.3 |

| 16 * 1.4 | 0.3 |

| 40 * 2.0 | 0.3 |

| 16 * 2.0 | 0.26 |

| 16 * 2.0 | 0.28 |

| 16 * 2.0 | 0.3 |

| 18 * 2.0 | 0.3 |

| 22 * 2.0 | 0.3 |

| 22.5 *1.5 | 0.3 |

| 26 * 2.0 | 0.3 |

| 26 * 2.0 | 0.32 |

| 32 * 2.0 | 0.3 |

| 32 * 2.0 | 0.32 |

| 32 * 2.0 | 0.35 |

High frequency welded aluminum alloy flat tube for automobile charge air cooler

| Tube size(mm) | Wall thickness(mm) |

| 64 * 8.08 | 0.5 |

| 64 * 7.6 | 0.45 |

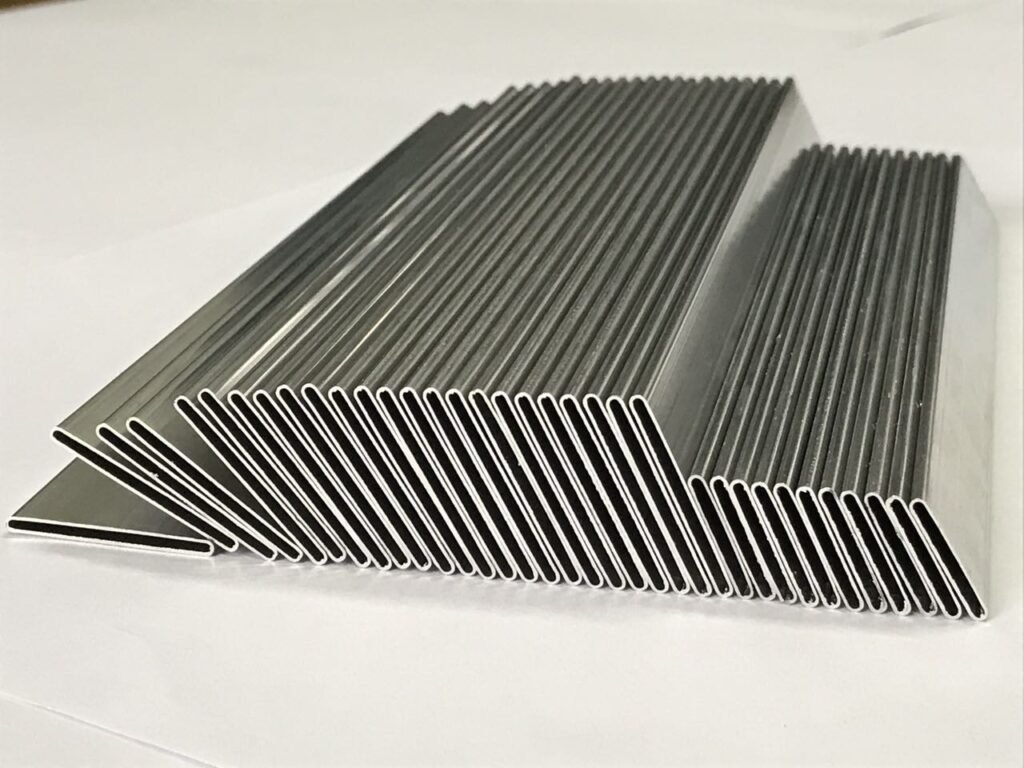

Product Features

Aluminum Alloy Flat Tube

1.High brightness, anti-corrosion, anti-oxidation.

2. Good straightness, no deformation.

3. High strength, good toughness.

4. Neat and smooth section, no burr.

5. High-frequency welding, precise specifications.

6.Flat tube size specification can be customized to meet your special requirements.

High Frequency Welded Aluminum Alloy Flat Tube

We use high quality aluminum alloy materials, we have advanced production equipment, strict requirements for production, and size specifications can be customized at affordable prices. The product application: automotive radiator/intercooler/supercharged air cooler, welcome to inquire and buy!

Product SKU: 99999

Product Brand: DAG

5