Product Introduction

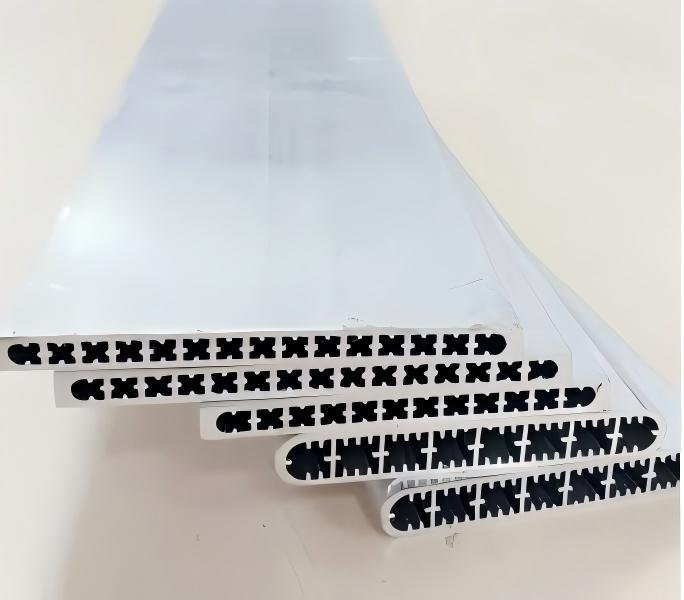

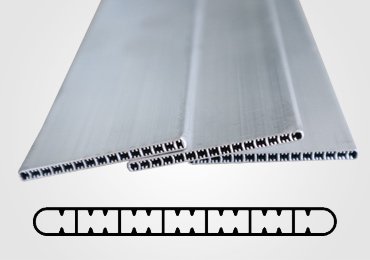

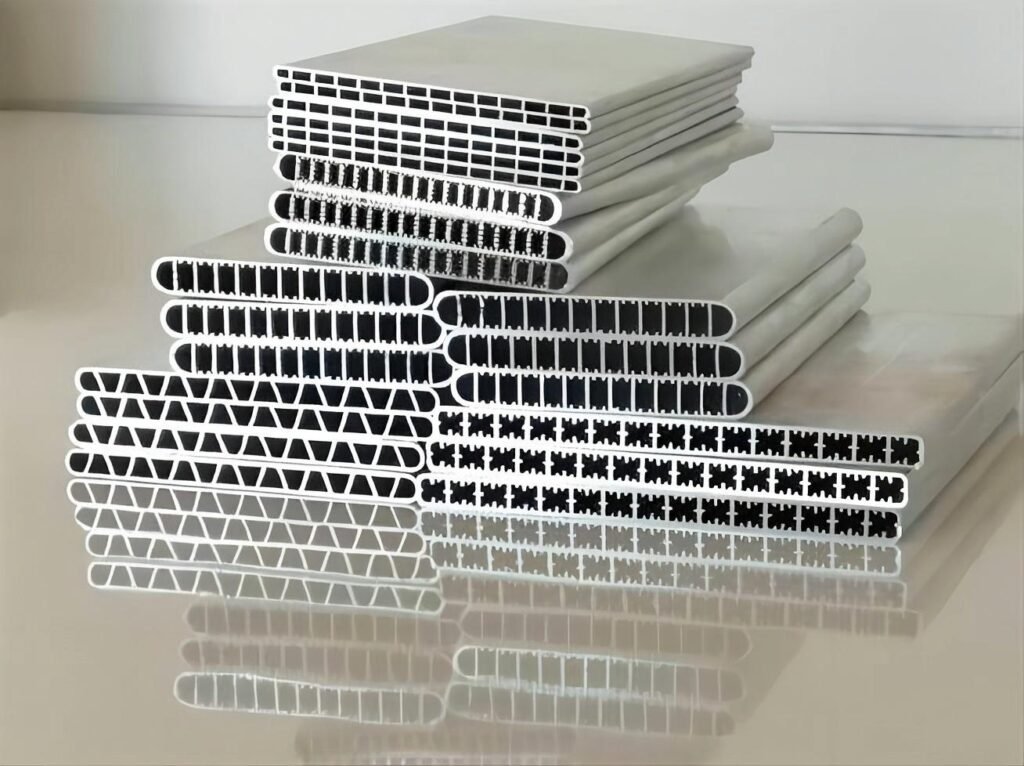

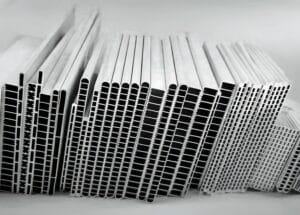

Aluminum Extrusion Micro Channel Tube

1. Aluminum extruded microchannel tubes are an alternative solution to copper tubes and welded aluminum manifolds, improving efficiency and reducing overall costs.

2. Can reduce system refrigerant charge by up to 35%.

3. Can improve energy efficiency/coefficient of performance by up to 10%.

4. Can reduce raw material consumption by more than 40%.

5. Can reduce manufacturing costs compared to aluminum and copper heat exchangers.

6. Can be easily recycled.

Product Advantages

Compared with traditional aluminum tubes, aluminum extruded microchannel tubes have greater advantages on the surface:

1. Improve quality and strengthen brazing, ensuring brazing quality is 100% corrosion-resistant and environmentally friendly.

2. Reduce costs: Cheap fin materials replace composite fin materials, thickness can be reduced by 30%, cost is greatly reduced, solder consumption is reduced, and defects are reduced.

3. Improve working conditions: No flux particles are contained in the air, reducing the emission of wastewater and harmful gases.

Product Applications

1. Heat transfer in the automotive market

2. Heat transfer in the HVAC&R (heating, ventilation, air conditioning and refrigeration) market

3. Air conditioning installation

4. Industrial production

5. Solar thermal utilization

Customizable Aluminum Extrusion Micro Channel Tube

Efficient heat exchange: Multiple holes increase the contact area between the fluid and the pipe wall, improving the heat exchange efficiency. Uniform fluid distribution: The porous structure can evenly distribute the fluid and reduce flow resistance. Lightweight design: Aluminum alloy material makes the pipe lighter and easier to install and maintain. Corrosion resistance: Through surface treatment, the corrosion resistance of the pipe is improved and the service life is extended. Fully customizable, affordable price, global shipping.Welcome to Place Your Professional Order!

Product SKU: 99999

Product Brand: DAG

5