Aluminum Micro-channel Tube Supplier

We are an ISO9001-2001 certified company with a large inventory of different types of microchannel tubes, including radiator aluminum flat tubes, microchannel parallel flow aluminum flat tubes, microchannel tubes for heat exchangers, microchannel condenser aluminum flat tubes, and many more.

◎ One-stop Design & Manufacturing Solutions

◎ Advanced Manufacturing Capabilities

◎ Free Samples are Available to Help You Check the Quality

◎ Customizable Sizes to Meet Your Needs

◎ Standard Existing Sizes to Save Your Initial Cost

◎ Fast Delivery of Standard Aluminum Tube Sizes

◎ We Can Accommodate Your Needs, No Matter How Big or Small Your Orders

◎ Affordable Price, Welcome to Buy

What is a microchannel tube?

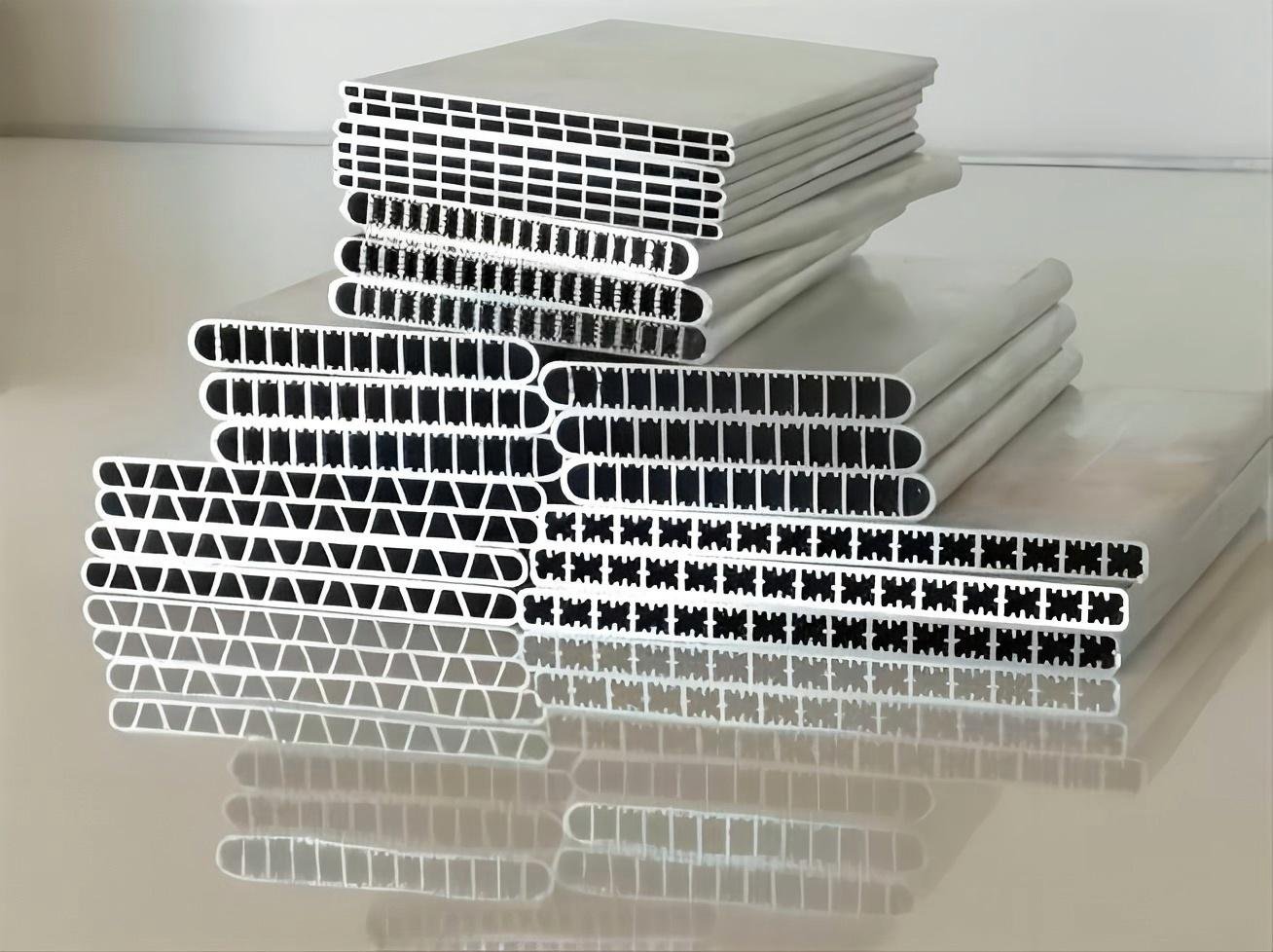

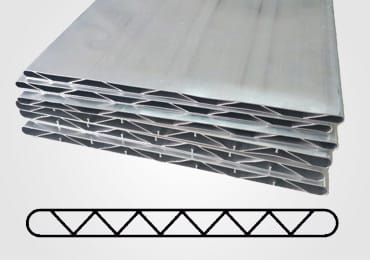

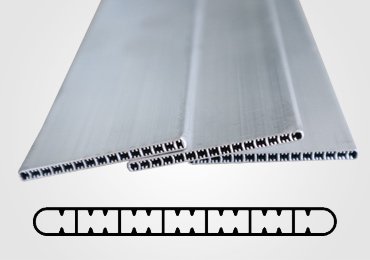

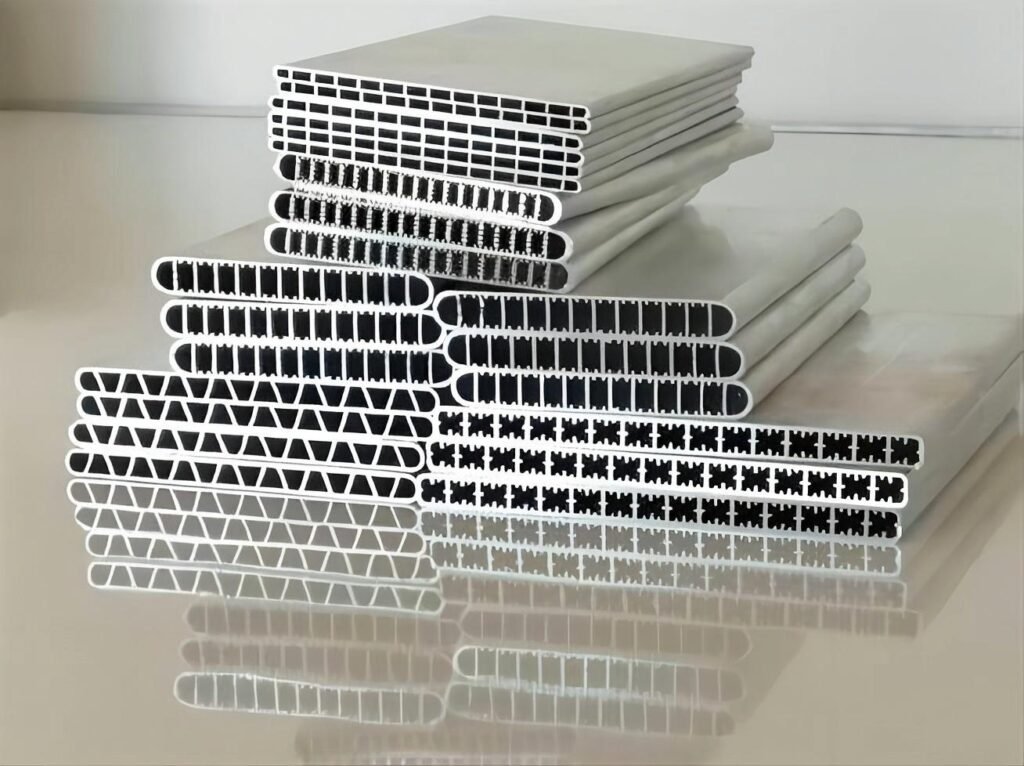

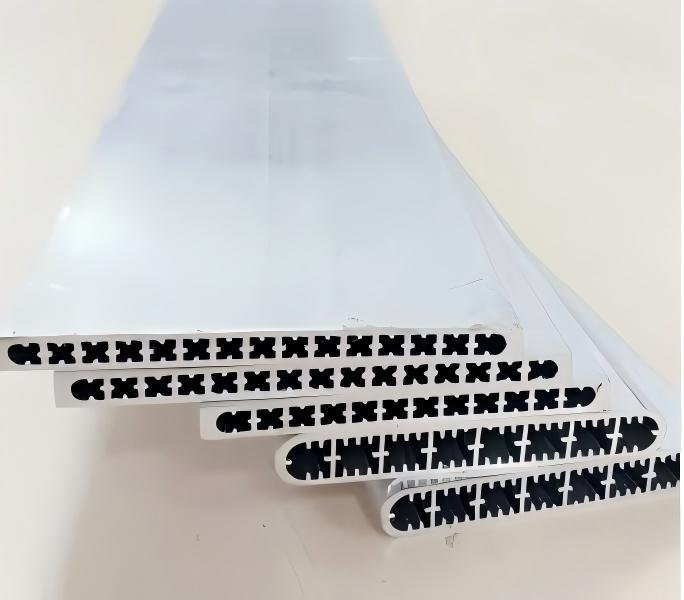

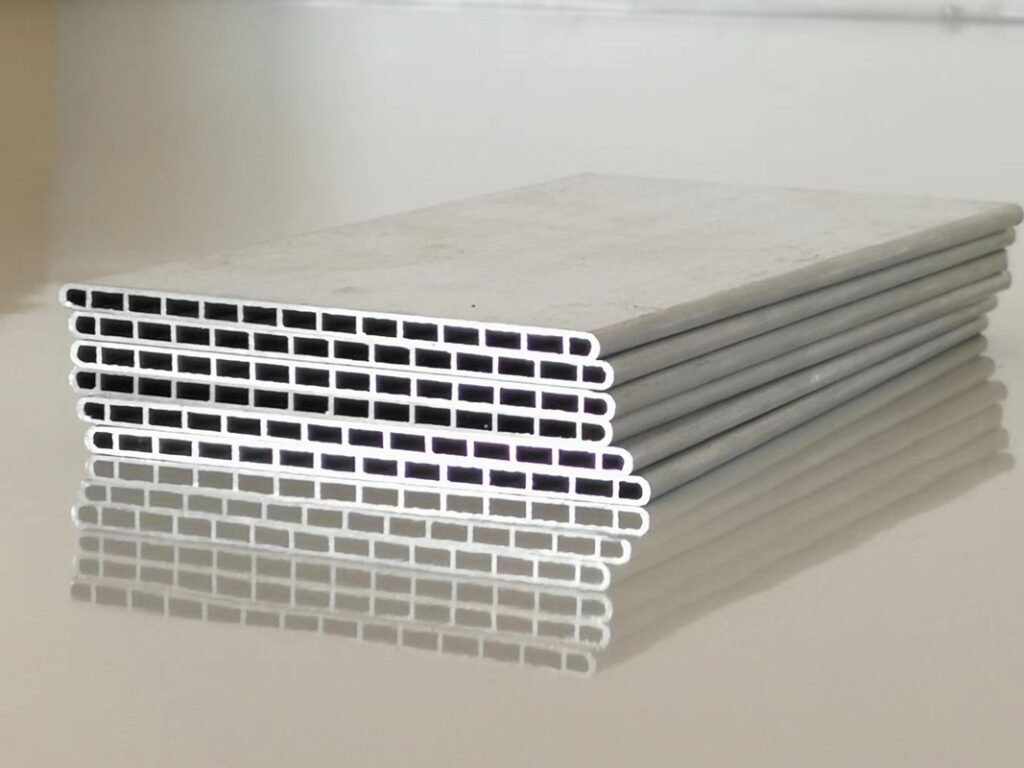

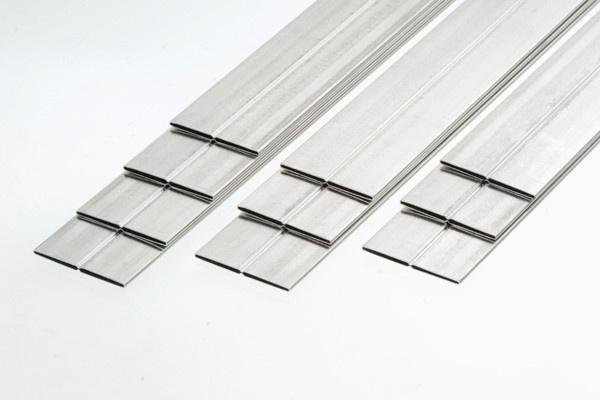

Microchannel aluminum flat tube (also known as “parallel flow aluminum flat tube or porous extruded tube”) is a thin-walled porous flat tubular material made of refined aluminum rods, through hot extrusion, and surface zinc spraying anti-corrosion treatment. Microchannel tubes are flat, rectangular and contain multiple channels. Since these channels have a higher surface area to volume ratio, they increase the heat transfer rate. Microchannel tubes are made in various sizes and aluminum alloys to ensure that they have the right characteristics for the application.

Microchannel tubes are mainly used in refrigerators, air conditioners, condensers, freezers, evaporators, gas stoves, automotive radiators, heat exchangers, HVAC and refrigeration systems, infrared detectors, microelectronics, power and process industries, aerospace, bioengineering, and powerful laser reflectors.

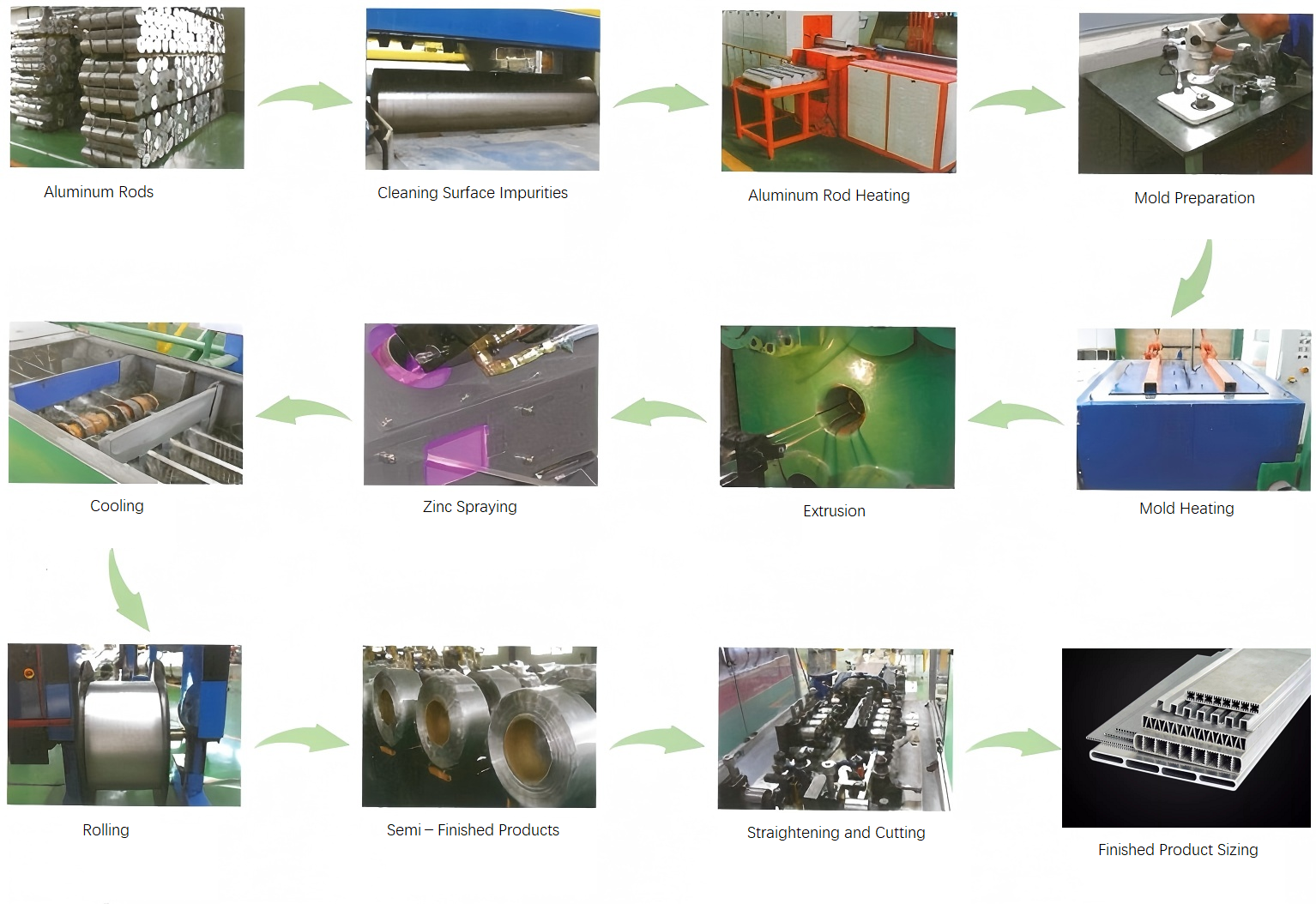

How Do You Manufacture Aluminum Microchannel Tube?

The aluminum parallel flow micro channel flat tube manufacturing process includes the following:

1. Collecting Aluminum Rods

In this stage, you will collect all the aluminum metal and then start the manufacturing process.

2. Cleaning Surface Impurities

Once you have enough aluminum, you need to clean it to remove any impurities that are stuck to the surface.

This will ensure the quality of the final product.

3. Heating Aluminum Rods

In this stage, aluminum undergoes thermal expansion because heat increases the vibration of atoms inside the metal.

This causes the aluminum to expand, increasing its length, volume, and surface area.

In addition, this process allows you to mold the aluminum into the desired shape.

4. Die Preparation and Heating

This process is required to make the aluminum ductile so that it is ready for the extrusion process.

In addition, this process allows the aluminum to be formed without breaking or cracking.

5. Extrusion

In this stage, you will extrude the aluminum alloy through a die.

The die has a specific cross-sectional profile that allows the aluminum to take the shape of the die.

6. Arc Zinc Spraying

This process helps you to coat the aluminum with zinc, which enhances its rust and corrosion resistance.

7. Cooling and Rewinding

In this stage, you will arrange and wind the wire on the aluminum to prepare it for the next stage.

8. Semi-finished Products

In this stage, the microchannel tube is still in its raw state and needs to be cut to specific sizes.

9. Straightening and Cutting

In this stage, you need to ensure that the microchannel tube is straight before cutting it to the required size.

10. Finished Product Shaping

In this stage, you need to ensure that the final product has the correct size and specifications before shipping.

11. Packaging

After the final product passes the inspection, you will package it and prepare it for shipping.

Finished Product Parameters

Microchannel tubing is typically made from 1000 series aluminum alloys. However, 2000, 3000, 5000, 6000, and 7000 series aluminum alloys are also available. We will customize microchannel tubing to your specific alloy requirements.

Products You May Be Looking for

Benefits of choosing our products

Features

Strong corrosion resistance, light weight, good thermal conductivity, good bending performance, strong forming ability, suitable pressure resistance, and narrow tolerance range.

Customization

We have highly trained engineers, years of manufacturing experience, cost-effective solutions, and first-class service to manufacture microchannel tubing to your specifications.

Quality Assurance

We always provide pre-production microchannel tube samples so that you can check the quality before mass production, and we always do a final inspection before shipping.

Delivery Time

If the microchannel tube size is in stock, it only takes 5-7 days to complete your order. For custom aluminum extruded microchannel tubes, it usually takes 25-30 days to complete production.

What Are The Benefits Of Microchannel Aluminum Tubes?

There are several benefits to using microchannel tubes in your applications:

1. Improved Heat Transfer Efficiency

Microchannel tubes have a high surface area to volume ratio.

This difference increases their efficiency in transferring heat from a heat source.

2. Low Material Cost

Aluminum is a readily available material that costs less than other types of metals.

This makes the cost of manufacturing microchannel tubes more reasonable than other competing materials.

3. Lightweight

Aluminum is lightweight compared to steel or other metals.

This allows you to use microchannel tubes in a variety of applications, as they do not significantly increase the overall weight of the product.

Microchannel tubes can be installed within the available space without making the product heavy.

4. Corrosion Resistance

Aluminum is corrosion resistant, making it ideal for manufacturing microchannel tubes.

This property makes it last for years and is a great value for money.

5. High Precision

Microchannel tubes have precise shapes and configurations that effectively dissipate heat.

6. High Surface Finish

Microchannel tubes are available in a variety of surface finishes to enhance the appearance and protective properties of your product.

Finished Product Display

.jpg)