Machine Introduction

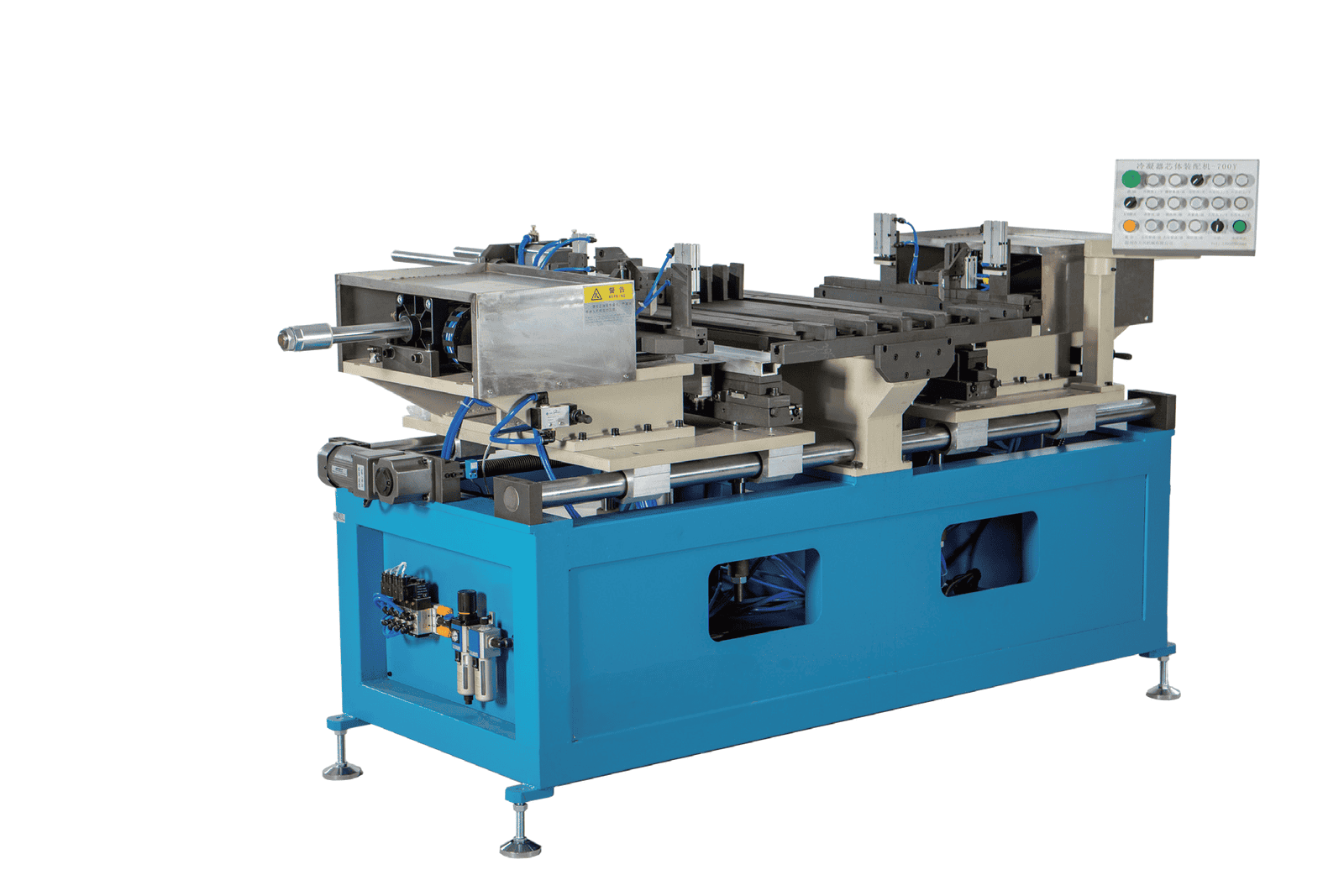

Pneumatic Car Aluminum Condenser Core Builder Machine

This specialized assembly machine is engineered for high-precision manufacturing of automotive condenser cores. It efficiently integrates header pipes, receiver driers, aluminum fins, and microchannel flat tubes into complete condenser assemblies for vehicle air conditioning systems.

Core Technical Features

1. Pneumatic Drive System: Utilizes advanced cylinder actuation for consistent, energy-efficient power transmission and reliable operation.

2. Precision Linear Guideways: Incorporates high-grade linear guides to ensure smooth, accurate movement and stable process control throughout the assembly cycle.

3. Hybrid Positioning System: Combines electrical sensors with precision mechanical fixtures for exceptional positioning accuracy and repeatability.

4. Superior Precision Standards: Delivers industry-leading process accuracy and component alignment tolerances.

5. Ergonomic Operation: Designed for simplified, rapid, and safe operation with minimal operator training required.

6. Multi-Product Flexibility: Easily adaptable for various condenser specifications, sizes, and production requirements.

Performance Advantages

The machine’s robust pneumatic control architecture and precision-engineered guide rail construction ensure exceptional durability and consistent production quality. Its integrated electrical-mechanical positioning technology guarantees critical component alignment within tight automotive industry specifications, making it ideal for both high-volume OEM and aftermarket condenser production.

Machine Parameters

Pneumatic Car Aluminum Condenser Core Builder Machine

| Core height (distance between main boards) | 280mm-800mm |

| Core width (main board length) | 200mm-700mm |

| Core thickness | 16mm-26mm |

| Pressure of pneumatic system | 0.4Mpa-0.7Mpa |

| Raw No. | One |

| Power | Single phase 220 (V) |

| Dimension | 1.2(T) |

| Equipment weight(L×W×H) | 2300mm× 1800mm×1200mm |

Aluminum Condenser Core Builder Machine

This machine is special equipment for assembling the core of an automobile condenser. It is used to assemble the manifold, harmonica tube, fin tube and flat tube together to form the automobile condenser. This machine has the advantages of high processing accuracy, high positioning accuracy, simple and fast operation, safety and reliability, etc.It is suitable for products of different sizes. Simple operation, fast, safe, reliable, and suitable. For detailed specifications, customization options, and competitive quotations, please submit your inquiry. Our technical sales team welcomes your consultation and stands ready to support your production requirements.

Product SKU: 5

Product Brand: DAG

5

Reviews

There are no reviews yet.