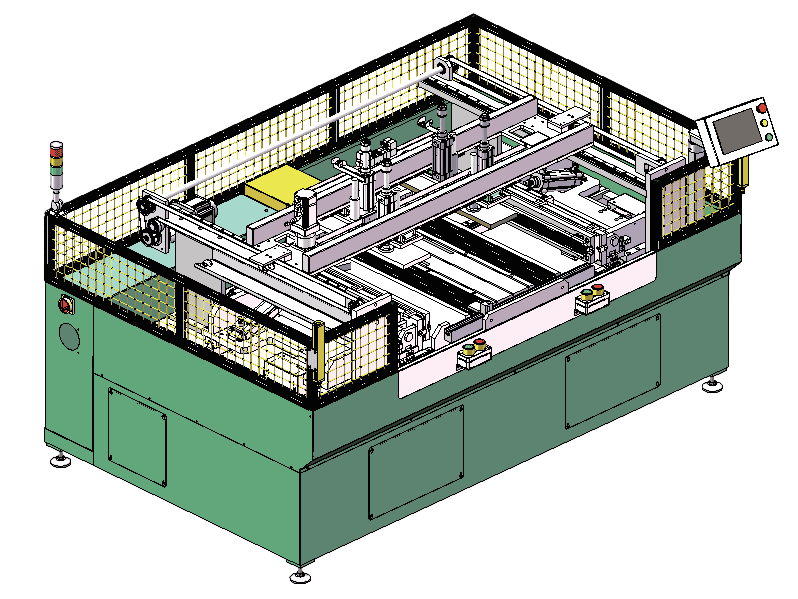

Machine Introduction

Servo Automobile Aluminum Radiator Core Builder Machine (Expansion Type)

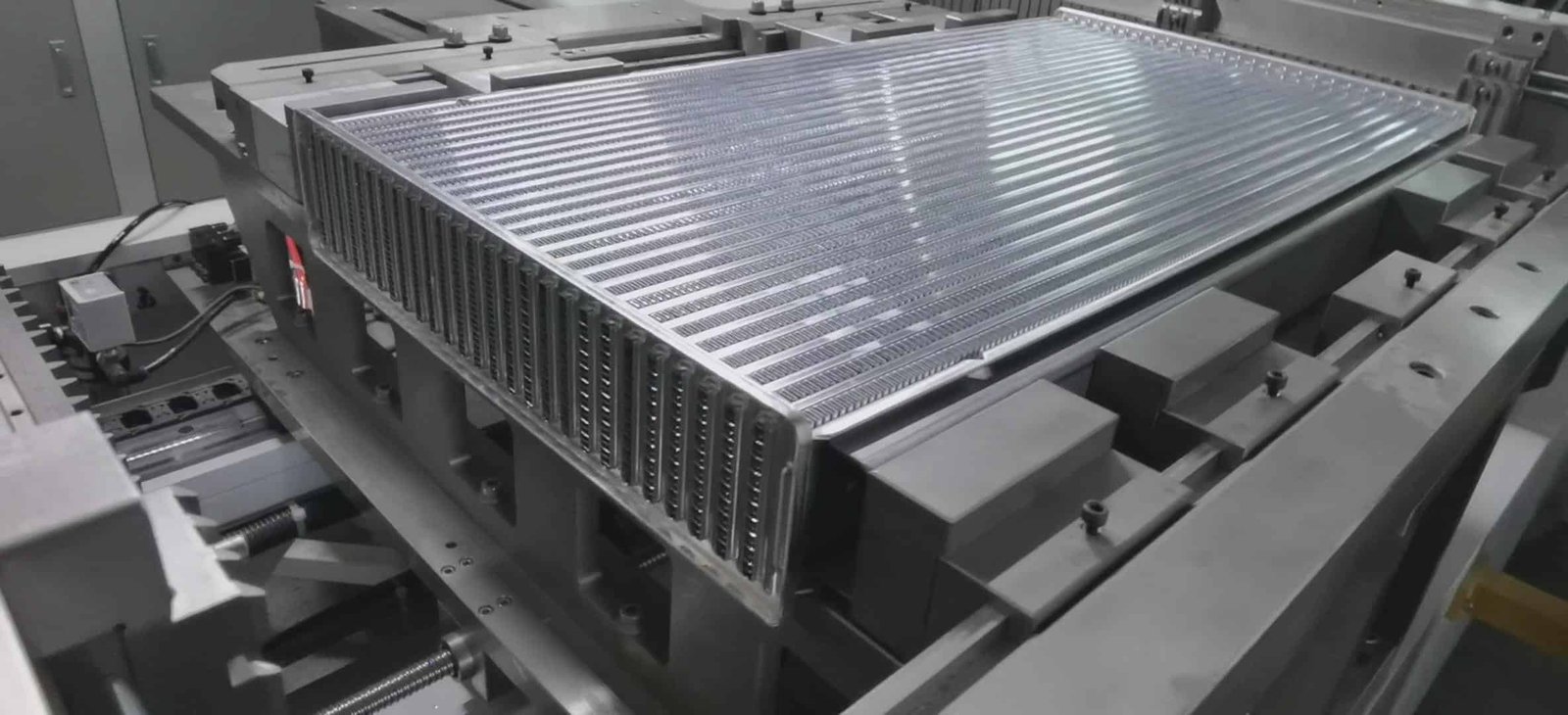

This specialized equipment is engineered for high-precision assembly of automotive aluminum radiator cores, integrating flat tubes, cooling fins, side plates, and header plates into a unified structure through controlled compression.

Advanced Technical Specifications

1. Servo Motor Pressing System: Utilizes precision servo motors to deliver consistent, programmable compression force.

2. Linear Guideway Mechanism: Incorporates high-precision linear guideways for smooth, accurate motion control.

3. Precision Aluminum Extrusion Platform: Features precision-machined aluminum profiles as the assembly bedplate.

4. Manual Domino-Style Tube Loading: Employs an efficient manual domino-pattern tube placement mechanism.

5. Chain Comb & Forming Pin Assembly: Integrates chain comb and forming pin configuration for precise tube and fin alignment.

6. Profile-Based Positioning: Utilizes shape-based positioning for accurate header plate location.

Enhanced Functional Capabilities

1. Flat Tube Expansion Function: Includes built-in tube expansion capability for secure joint formation.

2. Movable Press Cover: Equipped with a removable press cover for flexible operation and maintenance access.

Operational Performance Benefits

1. Intuitive operation with minimal training requirements.

2. Rapid die changeover system minimizes production downtime.

3. Reduced product changeover frequency enhances productivity.

4. Exceptional operational accuracy ensures consistent quality.

5. Stable, reliable performance for continuous production.

6. Multi-specification compatibility accommodates diverse radiator models and sizes.

Machine Parameters

Servo Automobile Aluminum Radiator Core Builder Machine

| Core height (distance between main boards) | 300mm~800mm |

| Core width (main board length) | 300mm~800mm |

| Core thickness | 16mm~32mm |

| Pipe thickness | 1.4mm-2.0 mm |

| Fin wave | 5mm~10mm |

| Raw No. | One or Two |

| Pressure of pneumatic system | 0.4Mpa-0.7Mpa |

| Power | 380 V、20A |

| Dimension(L×W×H) | 2400mm×1600mm×1500mm |

| Equipment weight | 2.2(T) |

Servo-driven radiator core builder machine (expansion type) for automotive heat exchanger production. Features quick-change worktables and stable servo drive. Cost-effective, low maintenance, multi-size compatible.

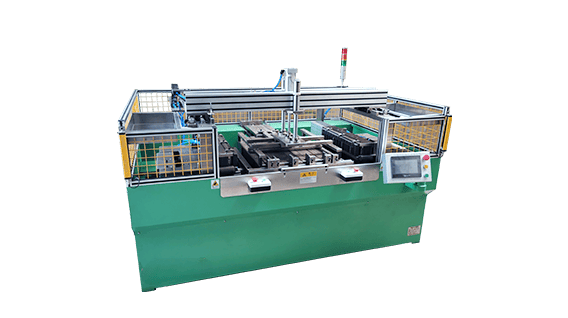

Servo Automobile Radiator Core Builder Machine (Expansion Type)

The equipment is equipped with special equipment for the automobile radiator core. The middle of the equipment is equipped with a base of a pipe working table. Through the replacement of the pipe working table, the assembly of different-sized cores is realized. The left and right sides are equipped with the main working slide, the servo motor is used to drive the auxiliary wire rod, and the automatic pipe mechanism is provided. The chain comb teeth and molding material needle combination, convenient and quick for replacement.. Cost-effective, low maintenance, multi-size compatible. For pricing and technical specifications, please submit your inquiry. Purchase orders welcome.

Product SKU: 3

Product Brand: DAG

5

Reviews

There are no reviews yet.