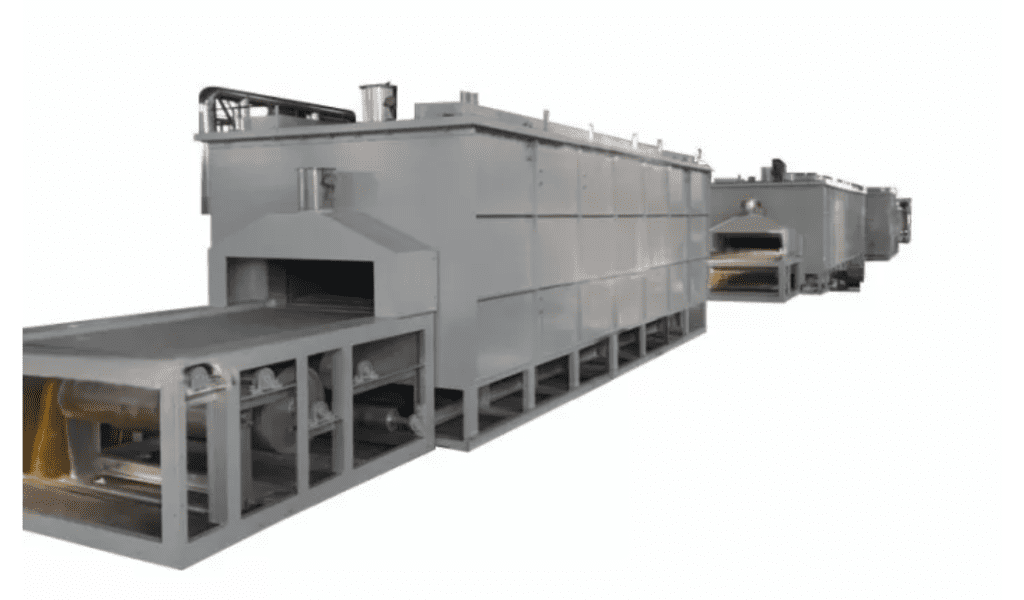

Continuous Aluminum Brazing Furnace of Brazing Radiator Intercooler Condenser

An aluminum brazing furnace system with a controllable atmosphere is mainly used for continuous brazing of aluminum car water tanks, oil coolers, intercoolers, warm air, tubular condensers, evaporators, parallel flow condensers, cascade evaporators, air coolers of power stations under nitrogen protection atmosphere.

Single-Chamber Vacuum Carrier Gas Brazing Furnace

Vacuum Carrier Gas Heating Aluminum Brazing Furnaces Are Mainly Used For Vacuum Carrier Gas Brazing Furnaces For Plate-Fin Heat Exchangers Such As Construction Machinery Heat Exchangers, Hydraulic Pump Station Heat Exchangers, And Automobile Heat Exchangers.

Aluminum Brazing Technology Overview

Brashing Definition

A welding method that uses a metal with a lower melting point than the base metal as a brazing filler metal. The liquid filler metal wets the base metal, fills the gap between the workpieces, and diffuses into the base metal.

During brazing, only the filler metal melts while the base metal remains solid. This requires the filler metal’s melting point to be lower than that of the base metal, and its composition also varies. The molten filler metal is drawn into and retained within the gap between the base metals through wetting and capillary action. The diffusion between the liquid filler metal and the solid base metal forms a metallurgical bond.

Generally speaking, brazing requires the use of solder and flux. Solders with a melting point below 450°C are called solder (an alloy of tin and lead), while those with a temperature above this are called brazing. Furthermore, joining using a polymer medium is called welding, which is distinct from brazing.

Introduction to Aluminum Brazing

Aluminum brazing began in the early 1930s. Today, many different brazing techniques are used. Atmosphere furnace brazing, vacuum brazing, and immersion brazing account for the majority of brazing equipment.

Features of Aluminum Brazing

For successful brazing, the surfaces must be clean and free of oxidation at brazing temperatures. Aluminum oxidizes easily in air and during the welding process.

The resulting aluminum oxide (Al2O3) has a high melting point, is very stable, and is difficult to remove. (At temperatures exceeding 250°C, high-temperature oxides form on the aluminum surface, which are difficult to remove with Noclok flux.) This oxide film hinders the melting and fusion of the brazing filler metal.

Aluminum’s high specific gravity makes surface preparation difficult, making defects such as slag inclusions, lack of fusion, and incomplete penetration more likely to occur.

The surface oxide film on aluminum, along with the high amount of moisture it absorbs, can easily lead to porosity in the weld.

This surface oxide film should be removed during welding. (The flux reacts with the oxide and displaces it, preventing the weld from coming into contact with the furnace air. This allows the filler metal to melt and be drawn into the weld by capillary action.)

DaG Custom Aluminum Brazing Furnace

Aluminum Brazing Furnace: it is used for brazing of air conditioners, oil coolers, radiators, air conditioner evaporators, condensers, radar network antennas, waveguides, and various plate-warped or tube-fin heat exchangers for automotive environmental protection products. It can also vacuum braze aluminum water-cooled plates and air-cooled boxes for electrical components in industries such as high-speed rail and new energy vehicles. It can also braze air separation products.

DAG specializes in standard and custom brazing furnaces, including Single-Chamber Vacuum Aluminum Brazing Furnaces, Giant Single-Chamber Vacuum Aluminum Brazing Furnaces, Single-Chamber Vacuum Carrier Gas Brazing Furnaces, Continuous Aluminium Radiator Brazing Furnaces, and Electric and gas Aluminum Brazing Furnaces.

The equipment size can be customized according to customer needs; detailed solutions are provided according to different product specifications, and high-precision equipment is designed.

What is the difference between vacuum brazing and continuous brazing?

The main differences between a vacuum brazing furnace and a continuous brazing furnace are working principle, application scenario, production capacity and product quality.

Working principle

Vacuum brazing furnace: Brazing is carried out in a vacuum environment. The furnace is evacuated to a high vacuum state (usually pressure ≤10^-3Pa) by a mechanical vacuum pump and a diffusion pump to avoid oxidation of the base material and the brazing material. No brazing flux is required, and the weld is pure. The heating system heats the parts and melts the brazing material to complete the brazing of the parts. The whole process is automatically controlled by the temperature controller.

Continuous brazing furnace: usually, a controlled atmosphere is used, such as protective gases, such as hydrogen and nitrogen, to reduce the risk of oxidation. The conveyor belt continuously feeds the workpiece into the furnace for brazing, which is suitable for mass production. Its working principle is to feed the workpieces into the furnace one by one through a conveyor belt for brazing treatment, which is suitable for large-scale production.

Application scenario

Vacuum brazing furnace: suitable for precision parts that require high cleanliness, high strength and high airtightness, such as electronic components, optical devices, aerospace, medical equipment, high-temperature alloy materials, etc. It is particularly suitable for the connection of complex structural parts and dissimilar materials, such as ceramic-metal, copper-stainless steel, etc.

Continuous brazing furnace: Suitable for standardised and large-scale production needs, such as automotive parts, home appliances, etc. Due to its efficient production capacity, it is suitable for large-scale

industrial production.

Production capacity and product quality

Vacuum brazing furnace: Low production capacity, but high product quality. Because it is carried out in a vacuum environment, oxidation and pollution are avoided, the weld is pure, the joint strength is close to the parent material, and the air tightness and corrosion resistance are excellent. Suitable for occasions with high requirements for product quality.

Continuous brazing furnace: High production capacity, suitable for large-scale production. Although the product quality is also high, it may be slightly insufficient in cleanliness and joint strength compared with the vacuum brazing furnace.

Equipment structure

Vacuum brazing furnace: Mainly composed of vacuum furnace body, heating system, vacuum system, cooling system, control system, etc., the furnace body needs to have good sealing and pressure resistance.

Continuous brazing furnace: It is mainly composed of a heating zone, an insulation zone, a cooling zone, a conveyor belt, a control system, etc. The length and temperature of the heating zone and cooling zone can be adjusted according to the process requirements.

Cost and maintenance

Vacuum brazing furnace: The equipment cost is relatively high, but since no brazing flux is required, the production cost and environmental pollution are reduced. The equipment maintenance cost is also relatively low because the structure inside the furnace is simple, which reduces the need for maintenance.

Continuous brazing furnace: The equipment cost is low, but the maintenance cost is high due to the need to frequently replace the conveyor belt and clean the residue in the furnace.

Aluminum Brazing Furnace For Sale

Giant vacuum aluminum brazing furnace: The vacuum system is a three-stage high vacuum system composed of a diffusion pump, a roots pump, and a mechanical backing pump. The size of the effective area can be customized according to customer needs.

Vacuum carrier gas heating aluminum brazing furnaces are mainly used for plate-fin heat exchangers, such as construction machinery and automobile heat exchangers. The power consumption of a Single furnace is about 450 KWh (800-1200C for high vacuum aluminum brazing), and the energy consumption is monitored in real-time.

The vacuum aluminum brazing furnace’s heating chamber is heated by nickel-chromium strips and the composite heat insulation structure of the multi-layer 1Cr18Ni9Ti reflective screen. The size of the effective area can be customized according to Customer needs and the computer control system.

It consists of a mesh belt conveyor system, a heating system, a cooling system, and an electronic control system. It can be brazed on aluminum heat exchangers such as radiators, intercoolers, condensers, evaporators, and heaters.

Electric & Gas Aluminium Brazing Furnace:Energy: Gas And Electric; Normal working temperature:200~250℃; Burner max power: 340kw; Natural gas consumption: 27M3/H.

Round Fluxer Aluminium Continuous Brazing Furnace:Brazing oven effective size:L6000×W1200×H250mm;

Total production line length:36.7M; Total power Electric power: 270KW;99.999%; Nitrogen supply:200m3/h (actual consumption: 90-120m3/h).

150-600mm/Min Aluminium Radiator Brazing Furnace is mainly used for brazing aluminum parts in a protective atmosphere. Normal operating temperature:600~650℃; Effective working size:1000mm(Mesh belt width)×250mm(Height of mesh belt); Speed:150~600mm/min; Length of heating zone:6M.

The aluminum radiator brazing furnace uses non-erosive brazing material under the nitrogen-protective atmosphere. Brazing Muffle Length:16M; Mesh Belt Speed:200-1400mm Depending On Furnace Size; Rated Working Temperature:650 Degrees Celcius

700KW Continuous Aluminium Radiator Brazing Furnace: Heating Method: resistance heating; Energy medium: electricity; Power (kW):700; Muffle length:10m; Rated working temperature:650 degree celcius

Continuous nitrogen brazing furnace: loading workpiece → flux spraying → drying → going through front curtain room (with nitrogen) → brazing (with nitrogen) → slag removing (nitrogen pre-heating) → going through static cooling room → going through rear curtain room (with nitrogen) → going through compulsive air cooling room → manual taking off cores from the belt.

Continuous Brazing Furnace 10 Meters Section: Length Of Brazing Furnace:6000mm; Width Of Brazing Furnace:1000mm; Height Of Brazing Furnace:250mm; Working Station Size:1000mm×250mm; Speed:150~600mm/min; maximum service temperature:700℃.

The flux used is NOCOLOK flux.

The drying oven is an essential part of the aluminum radiator brazing furnace.

The drying oven well dries the parts, and the dried parts are an essential precondition of a high-quality brazing process.

The drying oven works with gas to save operational costs for the overall CAB brazing furnace line.

Our air conditioner condenser brazing furnace is a core piece of equipment for air conditioner heat exchanger manufacturing. It achieves precise connections between aluminum and copper condenser components through high-temperature brazing.

This brazing furnace operates under nitrogen atmosphere protection, utilizing non-corrosive flux to continuously braze aluminum heat exchanger products including radiators, oil coolers, intercoolers, heater cores, tube-and-fin condensers, evaporators, parallel-flow condensers, stacked evaporators, and power plant air coolers.

This brazing furnace is an industrial heat treatment equipment designed for the mass production of aluminum alloy heat exchangers (such as automotive radiators and condensers). It is used for brazing aluminum radiators. Its core process is to achieve precise metal-to-metal connections in a protective atmosphere.

Our continuous aluminum brazing furnaces are primarily used for continuous brazing heat treatment of automotive aluminum intercoolers, radiators, air conditioning condensers, evaporator heater tanks, and aluminum oil coolers.

We can customize our products to meet your needs and budget at competitive prices. Inquiries are welcome, and we look forward to long-term partnerships.

This brazing furnace utilizes high-performance refractory materials, ensuring superior thermal insulation and minimal no-load losses. The brazing furnace’s protective atmosphere distribution system and airtight protective curtain are meticulously designed and crafted to minimize high-purity nitrogen consumption, resulting in energy-efficient and gas-efficient equipment and lower production and operating costs.

The continuous controlled atmosphere aluminum brazing furnace is an industrial heat treatment equipment designed specifically for aluminum workpieces. It utilizes a nitrogen protective atmosphere to achieve non-oxidative melt penetration of the brazing material, forming high-strength joints. It is suitable for large-scale continuous production.

It can be customized according to your needs, with affordable price. Welcome to inquire.

The continuous high-temperature brazing furnace is an industrial equipment used for non-oxidation brazing and bright heat treatment of metal materials. It uses hydrogen decomposed by an ammonia decomposition device and a purified hydrogen-nitrogen mixed gas as a protective atmosphere for continuous brazing and bright annealing.

The natural gas brazing furnace is an industrial brazing equipment that uses natural gas as a heat source. It is mainly used for the precision connection and heat treatment of metal workpieces; welding of automotive parts (aluminum radiators, air-conditioning components) and household appliance metal parts, with an annual production capacity of over 500,000 pieces.

Copper/iron/stainless steel brazing furnaces are industrial furnaces designed specifically for brazing copper, iron, stainless steel workpieces, and copper alloys. They are primarily categorized into vacuum brazing furnaces and continuous protective atmosphere brazing furnaces based on process requirements.

A horizontal vacuum brazing furnace, combining both vacuum and inert gas shielding technologies, is an industrial device specifically designed for high-quality joining of precision metal components (such as aluminum heat exchangers and automotive radiators).

We look forward to establishing a long-term partnership with you.

The mesh belt continuous brazing furnace is a widely used industrial furnace. It is an automated industrial equipment suitable for brazing and bright heat treatment of large quantities of metal workpieces (such as tableware, knives, and hardware).

We can customize our products to suit your needs and budget at competitive prices.

The water-cooled plate brazing furnace is an industrial equipment specially used for manufacturing liquid cooling plates in the cooling systems of electronic equipment (such as server chassis and new energy battery packs). It achieves precise sealing connection of metal flow channel structures through high-temperature molten brazing material.

Benefits of DAG Aluminum Brazing Furnace

Temperature

Consistent temperature control: The oven has advanced temperature control systems, ensuring consistent and accurate temperature throughout brazing. This helps achieve uniform and reliable brazing results.

Economy

Time-saving and cost-effective: With its efficient heating capabilities and precise temperature control, the oven reduces brazing time and minimizes energy consumption, resulting in cost savings for the production process.

Application

Versatile application: The radiator brazing oven is designed to accommodate various radiator sizes and configurations, making it suitable for multiple radiator production needs.

Humanize

User-friendly operation: The oven is designed with user-friendly features, making it easy to operate and maintain. Its intuitive controls and safety features ensure a smooth and hassle-free brazing process.

DAG Custom Aluminum Brazing Furnace Capabilities

DAG is a customer-focused business providing one-stop manufacturing of custom aluminum brazing furnaces. Our equipment complies with industry standards and regulations, ensuring your manufacturing process meets all required guidelines and certifications. We’ve been known as your reliable source for custom brazing furnaces for decades.

Our equipment is engineered to minimize waste and optimize resource use, reducing energy consumption and helping you achieve greater sustainability and cost savings.

People Also Ask

Q: What is a vacuum brazing furnace?

A: The vacuum brazing furnace realizes metal material welding by providing a high-temperature heat source in a low-pressure environment.

Q: What is a continuous brazing furnace?

A: The continuous brazing furnace is special equipment for continuous brazing and light annealing. It uses ammonia decomposition equipment to decompose hydrogen and purify the hydrogen-nitrogen mixture.

Q: What are the advantages and disadvantages of a vacuum and continuous brazing furnace?

A: Vacuum brazing has the advantages of high weld strength, long life, and high sealing, but its cost is high, and production efficiency is low. The continuous furnace has the advantages of high processing efficiency, low cost, and high production efficiency. However, its heat transfer effect is poor and is prone to deformation and tension.

Q: Does the aluminum Brazing furnace machine use gas?

A: The aluminum Brazing furnace machine can use natural gas as a productive energy source.

Q: How do you know what kinds of aluminum brazing furnace machine specifications should be customized?

A: The customers provide the production plan, the core’s most significant size, and the production workshop’s dimensions. The engineer will provide the best cost-effective solution based on the information provided.

Q: What’s the spray style for the aluminum brazing furnace machine?

A: The aluminum Brazing furnace machine’s spray can be divided into dry electrostatic powder and aqueous solution.

Q: Is the aluminum brazing furnace machine customized or of a standard size?

A: Customers customize the aluminum Brazing furnace machine according to their respective capacity requirements and product series specifications.