Machine Description

| Machine Name: | Radiator Core Builder Machine | Efficiency: | About 3-3.5 Minutes One Core |

| Driving Force: | Hydraulic | Flat Tube Width: | 20-32mm |

| Radiator Layer: | 2 Layers | Overall Dimension: | 2800 X 2200 X 1800mm |

| High Light: | Radiator Core Builder Machine, Vehicle Radiator Core Builder Machine, Aluminum Car Radiator Core Assembly Machine | ||

2 Row Radiator Core Builder Machine Features

- The flat tubes are distributed through a servo tube distribution device. And the overall comb teeth structure could ensure the flat tube positioning accuracy.

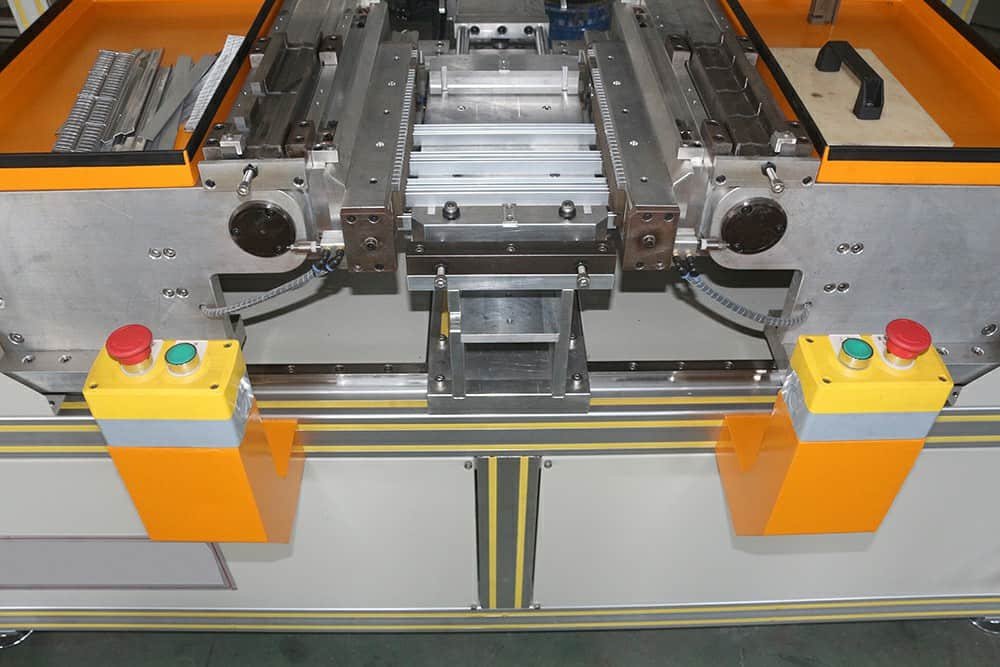

- The equipment is designed with 2-hand push buttons for safety operation.

- The equipment is accessible for operation, adjustment, and tooling replacement.

- The hydraulic cylinders control the left and right push mechanism and clamping mechanism.

- The flat tubes are distributed through a servo tube distribution device.

- The radiator core builder machine can be equipped with a header flaring mechanism, which is optional.

Machine Technical Parameters

| No. | Item | Specification | Unit |

| 1 | Flat tube length | 350—800 | mm |

| 2 | Flat tube width | Customer’s requirement | mm |

| 3 | Flat tube thickness | Customer’s requirement | |

| 4 | Flat tube quantity | Customer’s requirement | mm |

| 5 | Fin width | Customer’s requirement | mm |

| 6 | Fin height | Customer’s requirement | mm |

| 7 | Fin quantity | 80 | pcs |

| 8 | Layer | Two layers | |

| 9 | Center-to-center distance | Customer’s requirement | mm |

| 10 | Header installation method | Manually put into the header mold |

Power Supply of 2Row Radiator Core Builder Machine

| Wires: | 3-phase, 4-wire, 50Hz |

| Voltage: | 3AC 380V+/-5%, 50HZ |

| Rated power: | 6.5KW |

| Air source input pressure: | 0.6~0.8Mpa |

| Air consumption: | About 0.8m3/min |

| Working pressure: | 0.5Mpa |

| Electrical control system: | PLC and touchscreen |

2 Row Aluminum Automotive Radiator Core Builder Machine

Control: hybrid mechanical–pneumatic + PLC and color touchscreen. Operation: operator loads flat tubes, fins, side & header plates; hydraulic clamping guarantees OEM-level squareness and repeatability. Change-over: swap chains, comb inserts, header molds, clamp jaws—same-day conversion to any core in your range. Specs: fully customizable, factory-direct price, global shipping.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.