Introduction

When it comes to keeping your car’s engine cool, one crucial component plays a vital role—the automobile radiator. In this comprehensive guide, we will delve into the inner workings of a radiator, exploring its parts, operating principles, and how it helps maintain optimal engine temperature. Whether you’re a car enthusiast or simply curious about your vehicle’s cooling system, this article will provide you with all the essential information you need.

The Role of a Radiator in the Cooling System

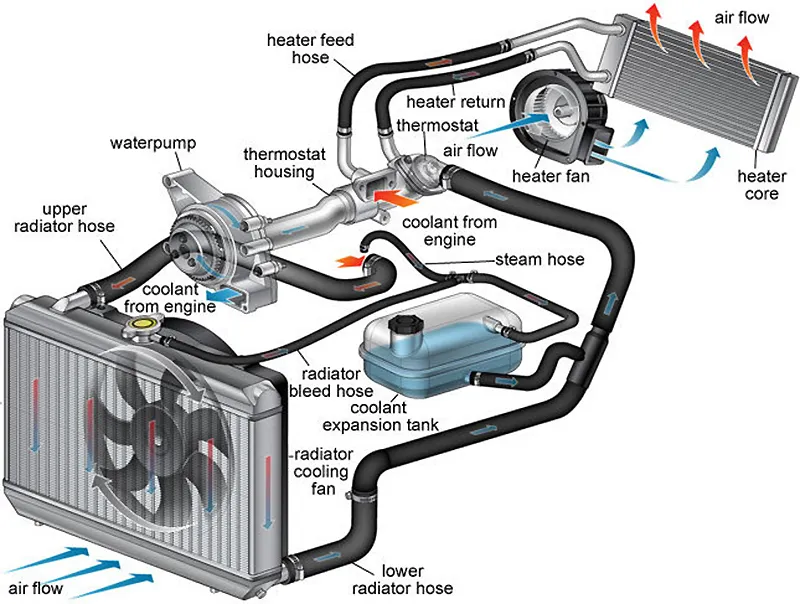

The radiator is at the heart of your car’s cooling system. Its primary function is to disperse a mixture of antifreeze and water throughout its fins, facilitating heat release from the engine. The radiator works with other components, such as the spur line, water pump, and fan clutch, to ensure the engine stays cool under various operating conditions.

The Spur Line and its Role

The spur line, an integral part of the cooling system, is crucial in aiding the radiator’s function. It dispatches warm coolant to the heater core, providing hot air when required. This feature allows you to adjust the temperature inside your vehicle, ensuring a comfortable driving experience regardless of the weather outside.

The Water Pump’s Contribution

Another critical component working in tandem with the radiator is the water pump. Its primary responsibility is circling the coolant throughout the engine, allowing for efficient heat transfer. Without the water pump, the coolant would not effectively flow through the engine, leading to overheating and potential damage.

The Fan Clutch’s Cooling Assistance

The radiator relies on the fan clutch to further enhance the cooling process. This component brings additional air into the radiator, reducing the antifreeze and water mixture’s temperature. By regulating the fan speed based on engine temperature, the fan clutch helps maintain optimal cooling efficiency.

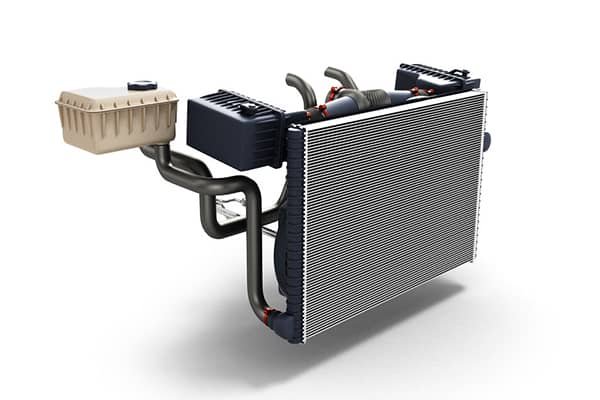

The Internal Components of a Radiator

To understand how a radiator functions, it’s essential to familiarize yourself with its internal components. The radiator consists of three main parts: the outlet and inlet tanks, the core, and the pressure cap. Each of these components serves a vital purpose in the cooling process.

The Inlet and Outlet Tanks

The inlet tank is crucial in guiding the hot coolant from the engine to the radiator for cooling. Once the coolant circulates through the radiator’s core, it exits through the outlet tank and returns to the engine. This continuous flow ensures that the engine remains at an appropriate operating temperature.

The Core: Cooling at its Core

At the heart of a radiator lies the core, a large metal plate with multiple rows of thin metal fins. As the hot coolant passes through the core, the fins facilitate heat dissipation, thus cooling down the coolant. This process allows efficient heat transfer from the engine to the surrounding air.

The Pressure Cap’s Importance

One often overlooked but crucial component of a radiator is the pressure cap. Its primary function is to seal the cooling system, maintaining the necessary pressure securely. If the pressure exceeds a certain point, the cap releases it, preventing potential damage or overheating. Without a functioning pressure cap, the radiator’s efficiency may be compromised.

How a Radiator Works: Step-by-Step Process

Let’s explore the step-by-step process of how a radiator works to gain a deeper understanding of its operation.

- Coolant Circulation Begins: The water pump starts circulating the coolant through the engine, absorbing heat along the way.

- Entering the Radiator: The hot coolant enters the radiator’s inlet tank, guided by the spur line.

- Cooling Down: As the coolant passes through the core, the metal fins facilitate heat dissipation, thus reducing the temperature.

- Please return to the Engine: Once the coolant reaches an appropriate temperature, it exits the radiator through the outlet tank and is ready to flow back into the engine.

- Continuous Flow: Coolant circulation and heat dissipation cycle continues, ensuring the engine remains cool even under demanding conditions.

Maintaining Radiator Efficiency: Tips and Best Practices

Following a few maintenance tips and best practices is crucial to ensure your radiator operates at peak efficiency. By incorporating these practices into your routine vehicle care, you can prolong the lifespan of your radiator and prevent potential issues.

Regular Coolant Checks and Flushes

Regularly checking the coolant level and quality is essential to maintain optimal radiator performance. Over time, coolant can become contaminated or lose its effectiveness. Flushing and replacing the coolant according to the manufacturer’s recommendations can prevent overheating and extend the radiator’s lifespan.

Inspecting Hoses and Belts

Inspecting the radiator hoses and belts for signs of wear or damage is crucial. Faulty hoses or belts can lead to coolant leaks or reduced coolant flow, negatively impacting the radiator’s efficiency. Regular inspections and timely replacements can help prevent these problems.

Cleaning the Radiator

Dirt, debris, and insects can accumulate on the radiator’s surface, obstructing airflow and hindering cooling efficiency. Regularly cleaning the radiator using a soft brush or compressed air can help maintain optimal performance.

Monitoring Temperature Gauges

An eye on your vehicle’s temperature gauges can provide early indications of radiator issues. If you notice consistent overheating or fluctuations in temperature, it’s essential to have your radiator and cooling system inspected by a professional.

Conclusion

The automobile radiator is critical to your car’s cooling system, ensuring your engine remains at an optimal operating temperature. Understanding its parts, operating principles, and maintenance requirements can help you take better care of your vehicle and prevent costly repairs. Following the tips and best practices outlined in this guide, you can keep your radiator in top shape, ensuring a smooth and efficient driving experience for years.

Remember, proactive maintenance and regular inspections are crucial to radiator longevity, so don’t overlook the importance of caring for this vital component of your vehicle.