Machine Description

| Machine Name: | Radiator Core Builder Machine | Efficiency: | About 4-5 Minutes One Core |

| Flat Tube Width: | 20-32mm | Radiator Layer: | 4 Layers |

| Overall Dimension: | 2600*2500*1800mm | Warranty: | 1 Year |

| High Light: | Radiator Core Builder Machine, Vehicle Radiator Core Builder Machine, Aluminum Car Radiator Core Assembly Machine | ||

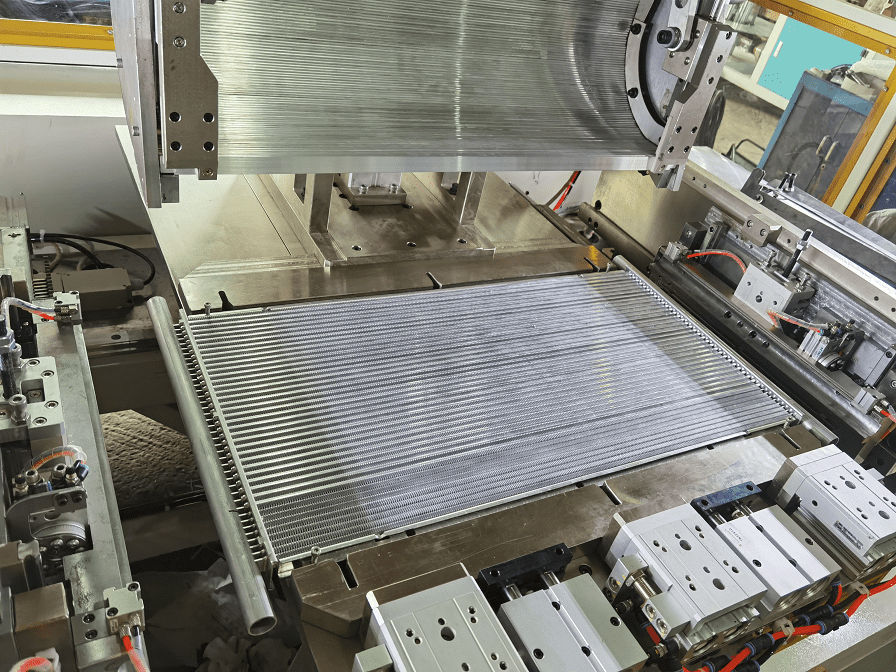

4 Row Aluminum Radiator Core Builder Machine

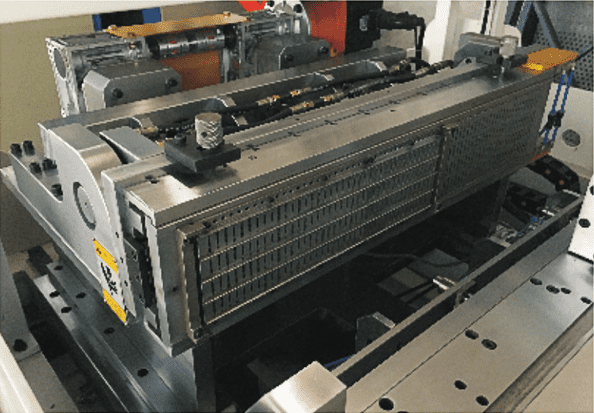

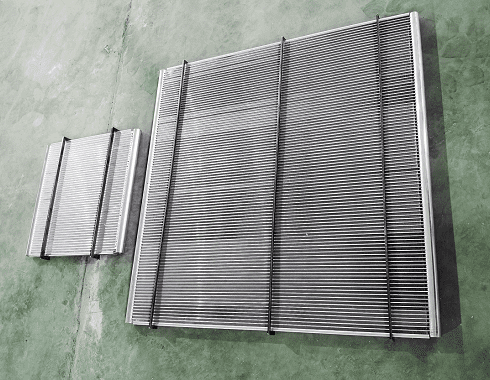

The radiator core builder machine has the advantages of stable and reliable working performance, easy operation, low noise, accurate positioning of flat tube center, and even distribution of fins. The assembled condenser core is highly accurate and has a good appearance, which ensures a better brazing effect in the brazing furnace.

Machine Technical Parameters

| Machine Name: 4-Row Semi-automatic Radiator Core Builder Machine |

| Radiator core assembled per time: 1 piece |

| Product: according to the customer’s drawing |

| Radiator fin height: 8.03mm |

| Core diagonal line tolerance:±1mm |

| Core height: ±1mm, core width: ±1.5mm |

| Distance between fin end and header plate: 2±1mm (could be adjusted through the positioning block). |

| Equipment mechanical movement time: 55s |

| According to the customer’s requirement, the assembly table is preserved with the aluminum fixture hole |

| Safety device: The radiator core builder is equipped with a photoelectric light curtain to protect the safety of the operator |

| Equipment power: 3P 5-wire, 380V 50Hz ≤13Kw |

| Equipment overall size: 2600*2500*1800mm |

| Compressed air: 0.6MPa 0.01m3/min |

| Equipment weight: about 3.5Ton |

Main Configuration

| Main Components | Item | Model/Brand |

| PLC | Mitsubishi | |

| Servo motor and servo amplifier | Mitsubishi | |

| Touch screen | Mitsubishi | |

| Low voltage components | Schneider | |

| Ball screw/linear rail | PMI | |

| Pneumatic components | Solenoid valve | AIRTAC |

| Pneumatic cylinder | AIRTAC | |

| Air and water separation | AIRTAC |

Custom Automotive Radiator Core Builder Machine

Aluminum Radiator Core Builder: automatically clamps header plates, side plates, fins and flat tubes into a rigid, furnace-ready core. Precise fit-up guarantees void-free CAB brazing and zero leak rates.

Product SKU: 6

Product Brand: DAG

5

Reviews

There are no reviews yet.