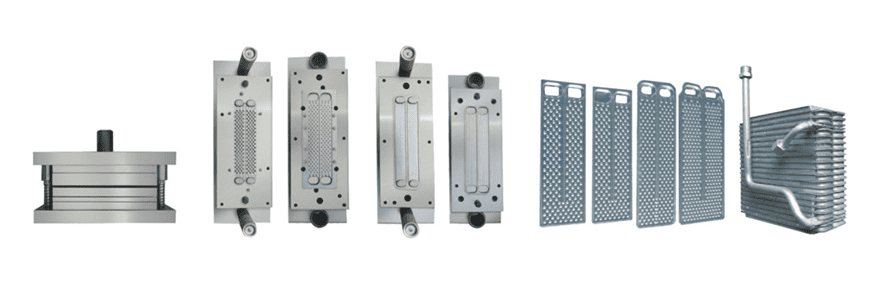

Heat Exchanger Punched Die

Laminated Evaporator Single-Progressive Die

Function

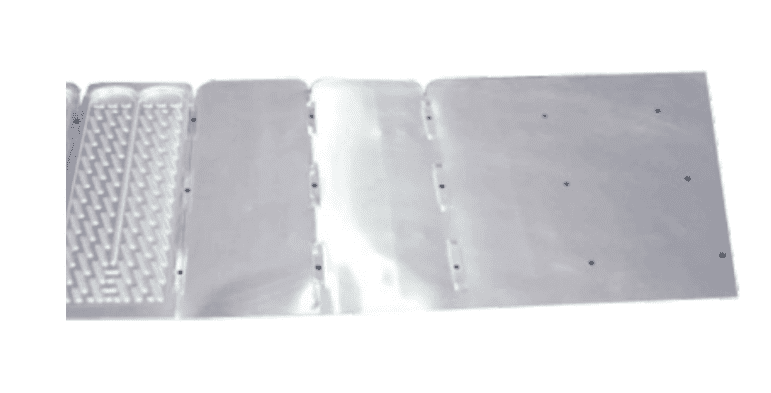

Precision one-hit stamping die that forms all critical features of a laminated evaporator plate—louvered louvers, refrigerant distribution channels, collar holes and locating notches—in a single press stroke.

Key Features

– Carbide (SKH-9 / MC53) inserts for 300 k-shot life

– ±0.01 mm blank accuracy, Ra ≤ 0.4 µm fin tip finish

– Quick-change cassette design; size swap < 10 min

– Compatible with 200–400 kN gap-frame or servo presses

– Optional in-die tapping & part marking station

Applications

Automotive HVAC laminated evaporators, battery chiller cold plates, R1234yf / CO₂ heat-pump micro-channel cores.

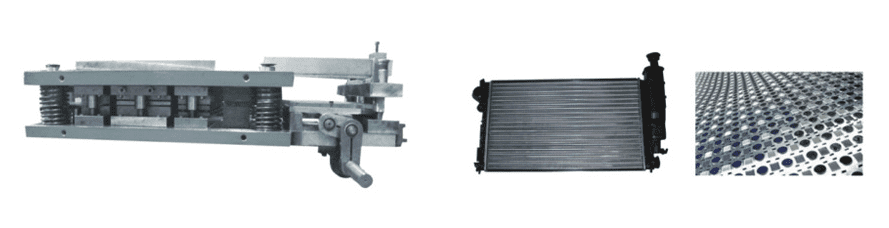

Continuous Fin-forming Progressive Die for Fin-and-Tube Heat Exchangers

Tool type

High-speed progressive stamping die

Strip width: 60–120 mm, thickness 0.08–0.30 mm (Al, Cu, Ni-coat Cu)

Pitch accuracy: ±0.02 mm, fin height deviation ≤ 0.03 mm

Speed: 200–300 SPM on 60–200 kN servo press; up to 7 lanes in one die

Key modules

1. Double-axis servofeed, 1–4 hole pitch step distance

2. Multi-stage louver, louvers breaking boundary layer, increasing air-side heat transfer ≈12 %

3. Micro-radius collar forming (R ≤ 0.2 mm) to maximise tube contact area

4. In-die oiling & vacuum scrap removal for burr-free edge

5. Quick-change cartridge for fin pattern swap < 10 min

Application

Condensers, evaporators, charge-air coolers, battery cold-plates for ICE & EV HVAC systems.

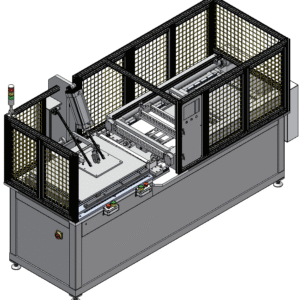

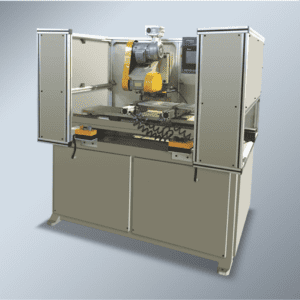

Car Heat Exchanger Punched Die for Sale

Precision Progressive & Single-Hit Tooling Application: Automotive HVAC laminated evaporators, battery chiller cold plates, R1234yf / CO₂ heat-pump micro-channel cores.Condensers, evaporators, charge-air coolers, battery cold-plates for ICE & EV HVAC systems. Designed & built by DAG Tech Shenzhen—fully custom, cost-effective, global delivery.

Product SKU: 20

Product Brand: DAG

5

Reviews

There are no reviews yet.