Aluminum brazing oven trends in 2025 bring big changes worldwide. Manufacturers and engineers notice how new technology in Aluminum Brazing Furnace can change furnace brazing services. These trends change how efficient, high-quality, and eco-friendly every market sector is.

- Automation and AI in aluminum furnace brazing services make things faster and better for cars and other industries.

- New flux materials and water-based fluxes help the market cut down on pollution and make furnace brazing services more eco-friendly.

- Advanced sensors and digital controls in aluminum brazing ovens give instant feedback, which makes products better and more reliable.

- Vacuum brazing technology helps the market make cleaner and stronger joints for cars, which makes furnace brazing services better and faster.

Companies in the market that use these aluminum upgrades get better furnace brazing services, higher product quality, and more efficiency.

Key Takeaways

- Automation and AI make aluminum brazing faster. They also help make car and plane parts safer and better.

- New green materials and energy-saving designs cut down on pollution. They also help save money.

- Digital monitoring and smart controls show data right away. This keeps brazing accurate and steady.

- Vacuum brazing ovens make cleaner and stronger joints. They do not need flux and are great for top-quality parts.

- Advanced materials like high-temp alloys and ceramic insulation help ovens last longer. They also use less energy.

- Industry 4.0 connectivity and simulation tools help companies improve brazing. These tools also help stop mistakes.

- Tough environmental and quality rules make companies use greener and smarter brazing ovens.

- Customizable ovens from makers like DAG give more choices. They also work better and make better products.

Aluminum Brazing Ovens in Modern Manufacturing

Essential Functions

Aluminum brazing ovens are very important in the market. They join aluminum parts together with strong bonds. These ovens use special air to stop oxides from forming on metals. This helps the filler metals move easily and make stronger joints. The ovens heat up aluminum parts and filler metals. The filler melts, but the base metals do not. This keeps the aluminum parts strong and in the right shape.

Brazing ovens give steady heat and a safe place for the process. This makes the brazing even and stops parts from bending. The market uses both continuous and vacuum brazing ovens. Continuous ovens are good for making lots of parts fast. Vacuum ovens stop oxidation and keep parts clean. These ovens help make strong, rust-proof aluminum joints for many uses, like cars and planes. Induction brazing ovens use electromagnetic fields to heat small areas. This is good for parts that cannot take much heat. The main benefits of aluminum brazing are steady quality, fast production, and strong joints.

Industry Applications

Aluminum brazing ovens are used in many industries. The car industry uses them for radiators, air conditioners, and coolers. The airplane industry needs them for heat exchangers, fuel systems, and frames. The defense industry uses them for radar, missiles, and armored vehicles. Power companies use brazing ovens for condensers and cooling systems. The HVAC market uses them for fridges and big machines. Medical and science fields use these ovens for MRI machines, lab tools, and surgery tools.

| Industry | Main Applications |

|---|---|

| Aerospace | Making heat exchangers, fuel systems, and frames |

| Defense | Radar, missile parts, and armored vehicles |

| Power Generation | Heat exchangers, condensers, and cooling systems |

| Commercial HVAC | HVAC systems, fridges, and machine heat exchangers |

| Automotive | Radiators, air conditioners, and coolers |

| Medical & Scientific | MRI machines, lab tools, and surgery tools |

The market likes aluminum brazing ovens because they join tricky parts with little bending and high trust. These ovens help car and plane makers meet tough safety and quality rules.

Key Challenges

People who make things with aluminum brazing ovens have some problems. They must keep ovens clean and fix issues early to avoid delays. Workers need to control the air and heat in the furnace very carefully. Skilled people and regular checks are needed for good brazing.

Some problems come from oil or dirt left on aluminum parts. These can stop the brazing from working right. Sometimes, customer designs are not good for brazing. This can mean parts need to be fixed or thrown away. The market also has trouble with matching materials and keeping surfaces clean. Induction brazing machines can be hard to use and cost a lot. They need skilled workers. The process must be watched closely to stop oxidation and loss of metal.

Tip: Working closely with suppliers and customers helps make sure parts are ready for brazing and fit the design.

These problems can hurt brazing quality, slow down work, and make furnace brazing services less successful in cars and planes.

Aluminum Brazing Oven Trends

Automation

Automation is a big trend for aluminum brazing ovens in 2025. More companies want automated systems for both continuous and vacuum ovens. Automated handling systems move aluminum parts quickly and with care. These systems use sensors and give feedback right away to keep things steady. Car and airplane makers use automation to meet tough rules and make more products.

Induction heating is important for automation in furnace brazing services. It heats aluminum parts fast and exactly, which helps stop mistakes and saves energy. Automated ovens can work twice as fast as old ovens. This helps companies make more heat exchangers, radiators, and car parts. Automation also makes things safer by removing open flames and needing fewer skilled workers. Companies waste less, make better joints, and use resources better.

Automation in aluminum brazing ovens helps companies work smarter and change with the market.

Digital Monitoring

Digital monitoring is changing how companies control the aluminum brazing process. New ovens use temperature profiling systems that go through the oven with the product. These systems record temperature data as it happens. Many thermocouples check the temperature at different spots on the aluminum part. The data logger saves this information so engineers can study and improve the process.

This technology gives companies more control over brazing. It makes sure the filler metal melts at the right time and the aluminum stays strong. Digital monitoring helps car and airplane makers keep high quality and follow strict rules. The data helps make furnace brazing services better, cut down on mistakes, and make products more reliable. Companies like this technology because it helps prove the process works and get certified.

Energy Efficiency

Energy efficiency is very important for companies in 2025. More people want eco-friendly aluminum brazing ovens, especially where there are strict rules. Both continuous and vacuum ovens now use better insulation, closed-loop cooling, and heat recovery. These features save energy and lower costs.

Companies are also using Industry 4.0 technologies. Real-time monitoring and predictive maintenance help stop surprise breakdowns and save energy. Modular furnace designs let companies grow and work better. Car and airplane makers benefit by lowering pollution and meeting green goals.

The table below shows how different aluminum brazing ovens compare. It shows how technology and energy use are different for continuous and vacuum ovens:

| Feature / Furnace Type | Radiation CAB Furnace | Combination Convection/Radiation CAB Furnace | Full Convection CAB Furnace | Vacuum Brazing Systems |

|---|---|---|---|---|

| Atmosphere | Nitrogen, oxygen-free | Nitrogen, oxygen-free | Nitrogen, oxygen-free | Vacuum (no atmosphere) |

| Heating Method | Radiation via heated muffle | Convection preheating + radiation brazing | Pure convection heat transfer | Vacuum heating |

| Temperature Control | Several independently heated zones | Independently controlled zones | ±3°C uniformity via recirculated nitrogen | Not detailed |

| Investment Cost | Low | Medium | Not specified | Not specified |

| Nitrogen Consumption | Efficient | Not specified | Not specified | Not applicable |

| Maintenance | Low | Not specified | Not specified | Not specified |

| Flexibility | Best for similar-size products in continuous flow | Handles different product masses and sizes, forgiving for intermittent production | Processes widest variety of products, shortest cycle time | Not detailed |

| Footprint | Not specified | Smaller footprint than radiation-only | More compact than other types with similar volume | Not detailed |

| Application Focus | High-volume production, e-mobility (EV battery coolers) | Flexible production, automotive industry | Automotive, heavy-duty, off-road heat exchangers | Not detailed |

| Environmental Impact | Supports green electromobility by reducing emissions | Not specified | Not specified | Not specified |

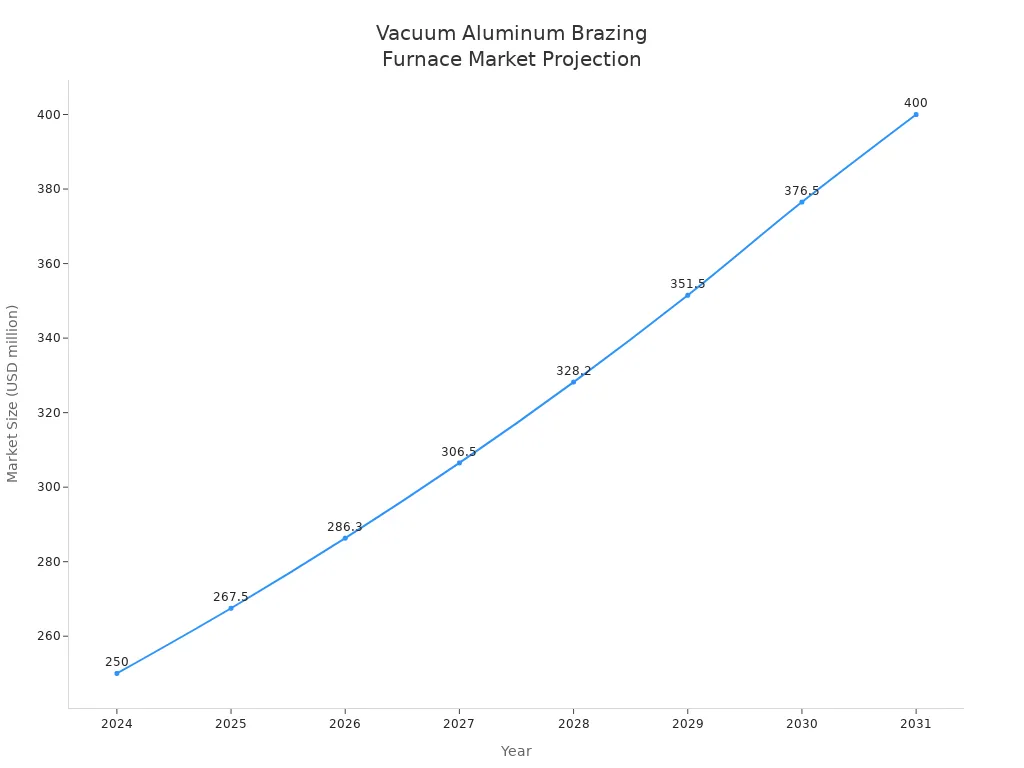

The market for vacuum aluminum brazing furnaces is growing quickly. The chart below shows how the market size is expected to grow from 2024 to 2031:

Vacuum systems have many good points for aluminum brazing. They control temperature well, heat evenly, and join different metals. Companies like these features for strong, reliable joints in cars and planes. Vacuum brazing also cuts down on waste and helps meet green goals.

Note: More people want vacuum aluminum brazing furnaces because of stricter rules and the need for better quality in new manufacturing.

In the future, aluminum brazing technology will keep focusing on automation, digital monitoring, and saving energy. Companies think these trends will make furnace brazing services, product quality, and green efforts better for cars and planes.

Advanced Materials

The market for aluminum brazing ovens is always changing. New materials are making a big difference now. Companies want their furnace brazing services to work better. They look for materials that can take high heat and not rust. These materials also need to last a long time.

Engineers use special alloys in these ovens. These alloys let ovens get hotter. They also help oven parts last longer. Many people want these strong alloys. They make furnace brazing services more dependable. Using better alloys gives stronger joints in aluminum parts. This helps companies follow strict quality rules.

Ceramic insulation is another key material. It keeps heat inside the oven and saves energy. Many furnace brazing services use ceramic fiber boards and blankets. These help ovens reach the right heat for aluminum brazing. They also keep the outside of the oven cooler. This protects workers from burns. The market likes these safety features.

Vacuum aluminum brazing ovens need good seals and gaskets. These parts keep air out during brazing. The market wants seals that can take high heat and chemicals. Good seals help make clean, strong joints in aluminum parts. This is very important for cars and planes.

Some companies use special coatings on oven parts. These coatings stop aluminum from sticking to the oven. They also protect against rust and chemical damage. The market likes these coatings because they make cleaning easier. Less cleaning means more time to make products.

Note: Advanced materials help companies save money and improve furnace brazing services. They also help companies save energy and make less waste.

The table below shows some advanced materials used in aluminum brazing ovens and their benefits for the market:

| Material Type | Main Use in Aluminum Brazing Ovens | Benefit for Market and Furnace Brazing Services |

|---|---|---|

| High-Temp Alloys | Oven structure, heating elements | Longer life, better heat control |

| Ceramic Insulation | Oven walls, doors | Energy savings, worker safety |

| Advanced Seals | Vacuum oven chambers | Clean joints, less contamination |

| Protective Coatings | Oven surfaces, conveyor belts | Less sticking, easier cleaning |

The market for aluminum brazing is getting bigger. Companies want furnace brazing services that use the best materials. They know advanced materials give better results in aluminum brazing. Both continuous and vacuum systems get better with these new materials. The market trusts these solutions for strong, clean, and reliable aluminum joints.

Aluminum brazing ovens with advanced materials help the market get better quality. Furnace brazing services become faster and cost less. The market will keep seeing new materials that make aluminum brazing technology even better.

Latest Trends in the Industry

Industry 4.0 Connectivity

Industry 4.0 connectivity is a big new trend. This technology changes how companies run aluminum brazing ovens. Smart controls and automation now use IoT and real-time monitoring. These tools help cut down on wasted time and save resources. Ovens can now send data all over the factory. This data shows how well ovens work, how much energy they use, and when they need fixing. Workers use this information to make furnace brazing services better and more efficient.

- Smart controls and automation use IoT for real-time checks.

- Ovens share data about performance and energy with the whole factory.

- AI helps ovens learn how they are used and change settings.

- Easy-to-use designs make ovens safer and help stop mistakes.

Here is an example of how this works. Large aluminum brazing ovens often have twelve big fans to keep heat even. Small sensors on each fan connect to IoT systems. These sensors watch the fans and warn workers before a fan breaks. In one case, data experts knew a fan would break 58 hours before it did. The repair team changed the fan in time and stopped a costly shutdown. This saves time and helps the market by keeping furnace brazing services running. Industry 4.0 also helps teams make quick choices and learn new skills.

The market wants more of these connected solutions. Companies want to grow and keep up with new brazing trends. Industry 4.0 technology helps them reach these goals.

Simulation and Modeling

Simulation and modeling tools are important for making aluminum brazing ovens work better. Many engineers use finite element modeling in programs like ANSYS Workbench. These tools let them test vacuum brazing and finish calculations faster. They also help fix problems with big, thin parts. The simulation shows real heating and cooling rates in a vacuum batch furnace. Engineers can move parts around in a virtual oven to try different setups.

This technology helps find what causes parts to bend or twist. For example, cooling too fast can cause stress. The right fixture design can lower temperature changes and stop bending. One study showed a new fixture design cut the biggest temperature difference from 141°C to 79°C. Bending during the process dropped from 275 µm to 31 µm, and final bending went from 14 µm to 8 µm. These results show how simulation helps make better joints.

Simulation tools also help set the best soaking time, cooling speed, and part spots. This leads to better furnace brazing services and helps the market grow. More companies want advanced modeling to improve quality and waste less. The market likes these tools because they help control and improve the process.

Regulatory Impacts

New rules are changing the industry’s latest trends. These rules focus on protecting the environment and saving energy. The 2024 IECC and other standards make companies build better ovens. Companies must use new technology to follow these rules. AI helps make brazing better and makes sure companies follow the law. This technology also helps ovens use less energy and make better products.

- Environmental rules and energy laws lead to new oven designs.

- Companies use new technology and AI to meet these rules.

- Following the rules means controlling the oven’s air and checking often.

- Groups like the EPA make sure companies follow the rules and use less energy.

- Companies pay a lot at first but save money and help the planet later.

- Research and new standards help companies stay ahead.

Now, companies use greener brazing methods to waste less and save energy. They also use eco-friendly materials in furnace brazing services. The market wants ovens that use less energy. Following new rules is very important for market growth and staying ahead. Companies that change fast do better in the market.

The aluminum brazing oven market grows when companies meet these new rules. Companies spend money on research to keep up with brazing trends. The market rewards those who focus on being green and making things better.

Future Trends in Aluminum Brazing Technology

The landscape of aluminum brazing is evolving rapidly, driven by a confluence of factors including stringent environmental regulations, the demand for higher performance components, and the relentless march of technological innovations in the industry.

These industrial brazing trends promise even greater efficiency, precision, and sustainability. Building on the foundational advancements in controlled atmosphere and vacuum brazing, the future of this critical manufacturing process highlights the key advantages of aluminum brazing: its ability to create lightweight, strong, and highly conductive joints, which are increasingly vital across various sectors.

One of the most significant overarching trends is the deep integration of Artificial Intelligence (AI) and Machine Learning (ML). While currently employed for compliance and basic optimization, AI’s role will expand dramatically.

Expect to see AI algorithms analyzing vast datasets from brazing cycles – temperature profiles, vacuum levels, gas compositions, and material properties – to predict optimal brazing parameters for new alloys or complex geometries.

This predictive capability will minimize trial-and-error, drastically reduce scrap rates, and ensure first-time-right brazing, leading to substantial cost savings and faster time-to-market for new products.

AI will also power predictive maintenance systems, identifying potential equipment failures before they occur, thereby maximizing oven uptime and operational efficiency. Real-time process adjustments, autonomously managed by AI, will become the norm, ensuring consistent quality even with variations in material batches.

Sustainability and “Green Brazing” will move beyond compliance to become a core competitive advantage. As regulatory bodies like the EPA impose stricter limits on emissions and energy consumption, brazing oven manufacturers will continue to showcase innovations in the industry.

This translates into the development of ultra-energy-efficient ovens that minimize heat loss, optimize energy source utilization (e.g., advanced electrical heating elements, improved insulation), and potentially integrate renewable energy sources.

Furthermore, research will focus on flux-less brazing techniques beyond vacuum brazing, such as active gas brazing, to completely eliminate the need for harsh chemical fluxes, which are often hazardous and require post-braze cleaning.

The industry will also explore methods to recycle and reclaim waste heat from brazing processes, further reducing the environmental footprint and operational costs.

The demand for eco-friendly filler materials and base alloys will also drive innovation, leading to the adoption of less toxic or more recyclable alternatives. These advancements reinforce the key advantages of aluminum brazing for environmentally conscious manufacturing.

The continuous drive for lightweighting and enhanced performance in industries like automotive, aerospace, and electronics means brazing technology must adapt to Advanced Materials Integration. This includes not only new generations of high-strength aluminum alloys but also dissimilar material joining.

Future brazing ovens and processes will need to precisely control thermal cycles to effectively join aluminum with materials like steel, copper, or even ceramics, opening up possibilities for novel component designs.

Hybrid brazing techniques, which combine elements of different methods (e.g., local induction heating within a controlled atmosphere, or laser-assisted vacuum brazing), will emerge to address these complex material combinations and intricate joint geometries. These are critical industrial brazing trends that expand the applicability of aluminum components.

Increased Automation and Robotics will elevate efficiency and safety to unprecedented levels.

Beyond simply conveying parts, robotic arms will be integrated for precise loading and unloading, even for complex or delicate assemblies.

Fully autonomous brazing cells, where parts are introduced and exit brazed with minimal human intervention, will become more common, especially in high-volume production environments.

This advanced automation will not only reduce labor costs but also improve repeatability and reduce the risk of human error, leading to consistently higher quality products.

These innovations in the industry directly contribute to the key advantages of aluminum brazing by ensuring consistent, high-quality output.

Process Miniaturization and Enhanced Precision will be crucial for the growing demand for smaller, more complex components in electronics, medical devices, and micro-electromechanical systems (MEMS).

This will necessitate brazing ovens capable of extremely fine temperature control and highly localized heating, potentially leveraging technologies like micro-laser brazing or highly focused induction heating.

The ability to braze tiny, intricate parts without compromising joint integrity will be a key differentiator.

Finally, the era of Industry 4.0 Connectivity and Digital Twins will profoundly impact brazing operations. Brazing ovens will be seamlessly integrated into broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

This connectivity will enable real-time data exchange, allowing for dynamic scheduling, material tracking, and comprehensive quality assurance.

Digital twins – virtual replicas of physical brazing ovens and processes – will enable manufacturers to simulate brazing cycles, test new parameters, and troubleshoot issues in a virtual environment before implementing changes on the actual equipment.

This will significantly reduce development time, optimize performance, and minimize costly downtime. The data generated will not only optimize current operations but also inform future design improvements for brazing ovens and components, driving continuous industrial brazing trends.

The future of aluminum brazing technology is bright, characterized by a relentless pursuit of efficiency, sustainability, and precision.

Companies that embrace these emerging industrial brazing trends through strategic investment in research, advanced technology, and skilled personnel will undoubtedly lead the market, further solidifying the key advantages of aluminum brazing for diverse industrial applications.

Brazing Oven Process Innovations

Controlled Atmosphere Brazing

Controlled atmosphere brazing ovens use nitrogen to keep aluminum safe. New ideas in the industry help furnace brazing services get better. Modern ovens have a stainless steel muffle. This keeps the nitrogen level steady inside the oven. The design helps heat spread out evenly to all parts. Proportional heat control lets the oven heat the muffle and products at the same speed. Fully automated systems move parts through the oven. Workers do not need to handle the parts much.

- Companies get better product quality and more reliable furnace brazing services.

- The process allows continuous furnace brazing, which helps make more products faster.

- Manufacturers use these new ideas to improve quality control for aluminum heat exchangers.

These changes help the market give steady results and meet strict rules for furnace brazing services.

Vacuum Brazing Technology

Vacuum brazing technology has changed how the market does brazing. This method takes away the aluminum oxide layer without using flux. The vacuum and magnesium vapor help the filler metal stick to the base metal. This makes strong joints, which are important for cars and planes.

The vacuum keeps the oven clean and dry. This stops oil and water from causing problems. It also lowers contamination and oxidation. Operators can control the temperature, holding time, vacuum level, and heating or cooling speeds. This control helps stop defects like corrosion or holes. The process heats parts evenly and helps metals mix better. The market gets more strong joints and higher production. Vacuum brazing helps meet the need for quality and speed in furnace brazing services.

Vacuum brazing ovens help the market get clean, strong, and reliable aluminum joints.

Conveyor and Continuous Processing

Continuous furnace brazing is now very important in the market. Conveyor systems move parts through each step without stopping. This cuts down on waiting and makes production faster. The market uses conveyor annealing furnaces for even heating and good temperature control.

| Advancement | Description | Impact on Throughput and Efficiency |

|---|---|---|

| Industry 4.0 Integration (AI, IoT) | Real-time monitoring and data analytics for process control | Reduces energy use by up to 20%, increases throughput |

| High-performance Insulation | Ceramics and aerogels minimize heat loss | Improves thermal efficiency, lowers operating costs by up to 30% |

| Conveyor Annealing Furnaces | Enables continuous processing, less downtime | Increases throughput, improves product consistency |

| Automation and Smart Manufacturing | Quick adjustments, seamless workflow | Enhances throughput and operational efficiency |

Continuous furnace brazing systems help the market make more products. These systems make the brazing process faster and more dependable. The market now wants strong joints and lower energy bills. Manufacturers can change schedules quickly and react to new orders. Continuous furnace brazing is a top pick for modern factories.

Conveyor and continuous processing help the market make more products and waste less in furnace brazing services.

Product Innovations: DAG Aluminum Brazing Furnaces

Continuous Brazing Ovens

DAG makes advanced continuous furnace brazing ovens for aluminum. These ovens use a conveyor belt and nitrogen gas to protect the parts. The design lets companies make lots of products quickly. This is great for making car radiators, oil coolers, and condensers. The process keeps the temperature steady and the air clean. This helps make strong and reliable joints in aluminum parts.

The ovens have heating, insulation, and cooling areas. Each area can be changed for different products. The smart control system lets workers change settings fast. This makes the process flexible and efficient. Companies like these ovens because they make many parts with steady quality. Car makers use them to meet strict rules and make lots of heat exchangers.

| Feature | Continuous Aluminum Brazing Furnace |

|---|---|

| Working Principle | Uses a controlled atmosphere (mainly nitrogen) with a conveyor belt for continuous brazing. |

| Application Scenario | Suitable for large-scale, standardized production such as automotive parts, home appliances. |

| Production Capacity | High throughput suitable for mass production. |

| Product Quality | High quality but slightly lower cleanliness and joint strength compared to vacuum brazing. |

| Equipment Structure | Composed of heating, insulation, cooling zones, conveyor belt, and control system; adjustable zones. |

| Cost and Maintenance | Lower equipment cost but higher maintenance due to conveyor belt replacement and residue cleaning. |

| Customization | Furnace size and process parameters adjustable to product specifications. |

| Atmosphere | Protective gases (nitrogen, hydrogen) to reduce oxidation risk. |

| Typical Products | Automotive radiators, oil coolers, condensers, evaporators, power station heat exchangers. |

DAG’s continuous furnace brazing ovens help companies save money and improve their services. The technology lets them make parts fast and keep the quality high.

Vacuum Brazing Ovens

DAG’s vacuum aluminum brazing ovens are used in aerospace and car making. These ovens create a strong vacuum that removes air and stops oxidation. The vacuum brazing process does not need flux, so the joints stay pure and strong. This is important for airplane parts, medical tools, and tricky assemblies.

Vacuum brazing ovens use automatic temperature controls. Workers can set the exact heat and cooling for each job. Companies trust vacuum furnace brazing for clean and strong joints. Airplane makers use these ovens for parts that must be airtight and not rust.

| Feature | Vacuum Aluminum Brazing Furnace |

|---|---|

| Working Principle | Operates in a high vacuum environment (pressure ≤10^-3Pa) to avoid oxidation; no brazing flux needed; automated temperature control. |

| Application Scenario | Ideal for precision parts requiring high cleanliness, strength, and airtightness, e.g., aerospace, medical, electronics. |

| Production Capacity | Lower production capacity but yields higher product quality with pure welds and strong joints. |

| Product Quality | Excellent weld purity, joint strength close to parent material, superior airtightness and corrosion resistance. |

| Equipment Structure | Includes vacuum furnace body, heating, vacuum, cooling, and control systems; requires good sealing and pressure resistance. |

| Cost and Maintenance | Higher equipment cost but lower maintenance; no flux needed reduces production cost and environmental pollution. |

| Customization | Custom sizes available; designed for high-precision brazing of complex parts like plate-fin heat exchangers. |

| Atmosphere | High vacuum environment to eliminate oxidation and contamination. |

| Typical Products | Aerospace components, medical devices, new energy vehicle parts, complex structural and dissimilar material joints. |

DAG’s vacuum furnace brazing helps companies meet the highest standards for aluminum parts. The technology makes sure joints are clean, strong, and reliable for important uses.

Customization and Flexibility

DAG designs aluminum brazing ovens that can be customized and are flexible. Companies can pick the oven size, type, and features they need. DAG offers both continuous and vacuum furnace brazing for cars and planes.

| Customization Aspect | Description | Benefit to End Users |

|---|---|---|

| Custom Manufacturing | Furnaces tailored to production plans, product sizes, and workshop dimensions | Ensures equipment fits specific production needs and space constraints |

| Equipment Size & Furnace Type | Options include vacuum, continuous, single-chamber, etc., with customizable size and effective area | Matches product specifications and production capacity, improving operational efficiency |

| Compliance & Design | Meets industry standards and regulations | Guarantees quality, safety, and regulatory compliance |

| Resource Optimization | Engineered to minimize waste and reduce energy consumption | Lowers operational costs and supports sustainability goals |

| Temperature Control | Advanced systems for consistent and precise temperature management | Achieves uniform brazing quality and reduces defects |

| User-Friendly Operation | Intuitive controls and safety features | Simplifies operation and maintenance, reducing downtime and training requirements |

DAG’s ovens use smart controls and full automation. These features help companies save time and make fewer mistakes. The ovens can run for long hours, so they save energy and last longer. OEM and ODM options let customers add their own brand. Companies get fast, flexible, and easy-to-use furnace brazing services.

Note: DAG’s focus on customization, efficiency, and smart controls helps companies get better results in aluminum brazing for cars and planes.

Implementation and Case Studies

Industry Adoption

Many companies now use advanced aluminum brazing ovens. The market is growing fast because of new technology and changing needs in cars and planes. Many things affect how quickly companies start using new furnace brazing services and better brazing methods.

- The price and supply of raw materials can change how much it costs to make things.

- Strict quality rules and certifications help keep the brazing process safe and reliable.

- The supply chain for pure aluminum alloys and flux materials affects how steady the market is.

- Research and development help make brazing materials better and bring new ideas.

- More people want lighter car and plane parts, so the market grows.

- Not enough skilled workers and expensive equipment can slow down new changes in some places.

- Rules that support saving energy and being green push the market to use eco-friendly furnace brazing services.

- Automated brazing makes production faster and more steady.

- The need to save fuel and cut pollution in cars and planes makes aluminum brazing more popular.

- Government rules that support lighter vehicles and green factories help the market grow.

These trends help companies find ways to make the brazing process better and meet new needs. Car and plane makers depend on advanced furnace brazing services to make strong, light parts. Companies that buy new brazing ovens and use automation get better results and grow faster.

Real-World Results

Real-life examples show how advanced aluminum brazing ovens help factories. The brazing process now makes stronger and more reliable joints for cars and planes. One example is the Advanced Multi-Step Brazing (AMSB) method. This process helped make special heat removal parts for fusion reactors. It shows how modern furnace brazing services work well.

Engineers used the brazing process to join tough materials like GlidCop and stainless steel. They pressed the parts together during brazing to stop leaks. The bonding layer got thinner, which made the joints better. Tests showed the joints were strong and reliable. The process also let them make cooling channels with curved or square shapes. These are important for cars and planes.

The brazed parts stayed strong and worked well, even in high heat and stress. The process let engineers join tungsten armor to copper alloy heat sinks. This is very important for parts that get very hot in planes. These results show that advanced furnace brazing services and ovens help the market get better joints, more precision, and stronger parts.

Companies that use advanced brazing ovens get better product quality, higher efficiency, and strong market growth. The car and plane industries are leading the way in using these new furnace brazing services and process improvements.

Practical Considerations

Selecting a Brazing Oven

People who make cars and planes need to pick the right brazing oven. The oven they choose affects how well furnace brazing services work. It also changes product quality and how fast the market grows. Companies want ovens that can make lots of car parts and also do careful work for planes. The table below lists what to look for when picking a brazing oven:

| Criteria | Description |

|---|---|

| Temperature Control | Precise ramp-up rate ( |

| Atmosphere Control | Use of inert gas (nitrogen) with very low oxygen (<2 ppm) and low moisture (dewpoint -20°F or better) to minimize oxidation |

| Furnace Customization | Furnaces should be customizable to meet specific production and process requirements, including muffle construction for high purity atmospheres |

| Uniform Heating & Cooling | Features like left-center-right trim for uniform part heating and controlled cooling of heavy loads ensure consistent brazing quality |

| Safety Compliance | Compliance with NFPA 86, NFPA-79, and UL508a standards for safe atmosphere operation |

| Material Quality & Reliability | Use of high-quality materials in furnace construction to ensure reliability and longevity |

People also think about how well the oven controls heat and air. They want ovens that can work with different metals. The market needs ovens for both continuous and vacuum brazing. The way parts are shaped and joined matters when picking an oven. Car and plane companies use these ideas to make sure their brazing is safe and high quality.

Evaluating ROI

Car and plane companies want to grow and get better furnace brazing services. They check if buying a new brazing oven is worth the money. They do a cost check to see how much they will spend and save. Some things they look at are:

- The price to buy new ovens.

- How much faster and better the ovens work, sometimes up to 30% better.

- If the ovens use less energy, which can be about 20% less.

- Lower bills for power and water, so they make more money.

- Making more car and plane parts in less time.

- Good things that last a long time, like helping the planet and beating other companies.

They also check if the oven maker is trusted and easy to work with. Talking to suppliers helps make sure the oven fits their needs. Reports show that buying energy-saving ovens pays off in three to five years. This helps the market grow and makes furnace brazing services better.

Tip: Ask experts for help when picking an oven. This helps companies get the best results and quality.

Compliance and Standards

Following rules is very important for car and plane companies. New rules change how brazing is done and what ovens to buy. Companies must use safe and green metals, like those without cadmium. Ovens must work with these new metals and ways of brazing.

Industry 4.0 brings smart controls and live checks to furnace brazing services. Buyers want ovens with these tools to keep quality high. Using induction and vacuum brazing helps make more parts and stops rust, which helps the market grow.

The table below shows some important rules and how they matter:

| Standard/Section | Key Requirements | Impact on Purchasing Decisions |

|---|---|---|

| AMS2750 (Class 2) | Requires ±10°F temperature uniformity in furnaces to prevent incipient melting in aluminum heat treating. | Buyers must select ovens capable of precise thermal control and instrumentation to meet this tolerance. |

| Nadcap AC7102/2 (Aluminum Heat Treat) | Contains 13 sections addressing furnace class, instrumentation, heating environment control, racks/fixtures, and quench systems. Includes requirements such as tracking rework cycles, controlling combustion products above 400°F, and ensuring proper part spacing and quench delay. | Purchasing decisions are influenced by the need for ovens that comply with these process controls and documentation requirements to ensure quality and compliance. |

Car and plane makers also think about changes in getting supplies and helping the planet. These things make them want better furnace brazing services. Quality is always the most important thing when buying an oven. This makes sure the brazing process gives strong and safe results.

The aluminum brazing oven market is changing quickly in 2025. Companies notice new trends like digital controls, automation, and better alloys. Energy efficiency and strong supply chains are now very important. Companies using advanced furnace brazing services, such as DAG, get better quality and lower costs. They also make products faster. To keep up, companies should check their aluminum processes and invest in new furnace brazing services. They should also pay attention to global trends. Next, companies can use automation, digital tools, and new alloys to become leaders in the market.

FAQ

What is the main benefit of using aluminum brazing ovens in the market?

Aluminum brazing ovens help make strong and clean joints. These ovens are used for car parts and heat exchangers. Companies use them to make products that last longer and work better.

How do furnace brazing services improve production efficiency?

Furnace brazing services use special ovens to join parts fast. This process helps companies waste less and save time. They can make more products in a shorter time, which helps them work better.

Why do companies choose vacuum aluminum brazing ovens?

Vacuum aluminum brazing ovens take out air and stop oxidation. These ovens make sure joints are clean and strong. Companies use them to meet tough rules for cars and planes.

What industries rely most on furnace brazing services?

Many industries use furnace brazing services, like cars, planes, HVAC, and power plants. They need strong joints for things like radiators and heat exchangers. These companies trust advanced ovens for the best results.

How does automation impact furnace brazing services?

Automation helps furnace brazing services by making work faster and easier. Machines move parts carefully and with great accuracy. This means companies get better and more steady results.

What makes DAG aluminum brazing ovens stand out in the market?

DAG aluminum brazing ovens can be changed to fit different needs. They use smart controls and save energy. Companies use them for both big jobs and careful, detailed work.

How do companies ensure quality in furnace brazing services?

Companies use strict temperature checks and digital tools. These steps help keep heating even and joints strong. Sensors and regular checks make the process safe and reliable.

Are furnace brazing services environmentally friendly?

Many furnace brazing services now use ovens that save energy. They also use materials that are better for the planet. Companies want to lower pollution and follow new rules.